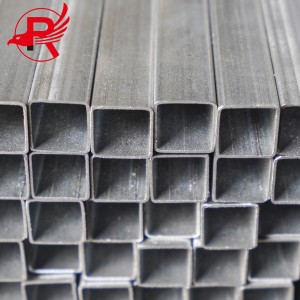

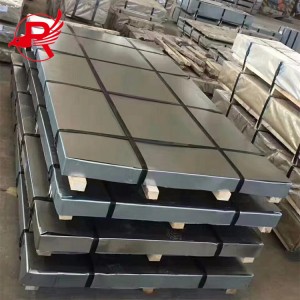

Factory 2×2 Galvanized Hollow Section 14 Gauge Tubing Iron Square Steel Pipes

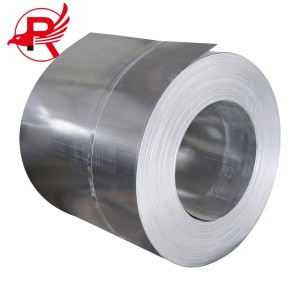

Galvanized square pipe is a kind of hollow square cross section steel pipe with square section shape and size made of hot rolled or cold rolled galvanized strip steel or galvanized coil as blank through cold bending processing and then through high frequency welding, or the cold formed hollow steel pipe made in advance and then through hot dip galvanized square pipe

1. Corrosion resistance: Galvanizing is an economic and effective rust prevention method that is often used. About half of the world's zinc output is used in this process. Not only does zinc form a dense protective layer on the steel surface, but it also has a cathodic protection effect. When the zinc coating is damaged, it can still prevent the corrosion of the iron base material by cathodic protection.

2. Good cold bending and welding performance: mainly used low carbon steel grade, the requirements have good cold bending and welding performance, as well as a certain stamping performance

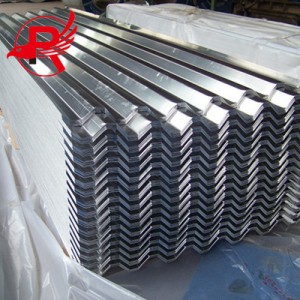

3. Reflectivity: It has high reflectivity, making it a barrier against heat

4, the coating toughness is strong, galvanized layer forms a special metallurgical structure, this structure can withstand mechanical damage in transport and use.

Application

Because galvanized square pipe is galvanized on the square pipe, so the application range of galvanized square pipe has been greatly expanded than square pipe. It is mainly used in curtain wall, construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation bracket, steel structure engineering, power engineering, power plant, agriculture and chemical machinery, glass curtain wall, automobile chassis, airport and so on.

|

Product Name

|

Galvanized Square Steel Pipe

|

|||

|

Zinc Coating

|

35μm-200μm

|

|||

|

Wall Thickness

|

1-5MM

|

|||

|

Surface

|

Pre-galvanized, Hot dipped galvanized, Electro galvanized, Black, Painted, Threaded, Engraved, Socket.

|

|||

|

Grade

|

Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D

|

|||

|

Tolerance

|

±1%

|

|||

|

Oiled or Non-Oiled

|

Non-Oiled

|

|||

|

Delivery Time

|

3-15 days (according to the actual tonnage) | |||

|

Usage

|

Civil engineering, architecture, steel towers, shipyard, scaffoldings, struts, piles for suppression of landslide and other

structures |

|||

|

Package

|

In bundles with steel strip or in loose, non-woven fabrics packings or as per customers' request

|

|||

|

MOQ

|

1 ton

|

|||

|

Payment Term

|

T/T LC DP

|

|||

|

Trade Term

|

FOB,CFR,CIF ,DDP,EXW

|

|||

Details

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.