-

Manufacture Q345 Cold Rolled Galvanized C Channel Steel

Galvanized C-shaped steel is a new type of steel made of high-strength steel plate, then cold-bent and roll-formed. Compared with traditional hot-rolled steel, the same strength can save 30% of the material. When making it, the given C-shaped steel size is used. C-shaped steel The forming machine automatically processes and forms.

Compared with ordinary U-shaped steel, galvanized C-shaped steel can not only be preserved for a long time without changing its material, but also has relatively strong corrosion resistance, but its weight is also slightly heavier than the accompanying C-shaped steel. It also has a uniform zinc layer, smooth surface, strong adhesion, and high dimensional accuracy. All surfaces are covered by a zinc layer, and the zinc content on the surface is usually 120-275g/㎡, which can be said to be a super protective one. -

Hot Selling 10# Galvanized U Beam Steel C Channel U Channel Price

The performance of galvanized channel steel is more stable, reliable and safe. In addition to the characteristics introduced above, galvanized channel steel still has many advantages. For example, it will not rust after galvanizing and has a long service life, so that the construction unit can use it in a certain way. To a certain extent, costs are reduced and expenses are saved. Galvanized channel steel has been widely used due to its outstanding characteristics and can be found in various constructions.

-

China Supplier Galvanized ASTM A53 Iron Structural U/C Steel Channel for Construction

Construction engineering: Galvanized channel steel can be used for building structures, roof trusses, stairs and other components, and has good corrosion resistance and strength. Bridge engineering: Galvanized channel steel can be used as supporting components, guardrails, etc. of bridges. It can withstand large loads and is corrosion-resistant. Automobile manufacturing industry: Galvanized channel steel is widely used in body structures, chassis, wheels and other components during the automobile manufacturing process, improving the overall strength and corrosion resistance of the automobile.

-

Galvanized Steel Channel Q235

Strong anti-corrosion ability: Galvanized channel steel is treated with galvanizing to form a zinc layer on the surface, which can effectively prevent oxidative corrosion and extend the service life of the channel steel. High strength: After cold-bending and hot-dip galvanizing, galvanized channel steel has high strength and can withstand larger loads. Good weldability: Galvanized steel is not prone to cracks and deformation during the welding process, and the welded joints are strong and reliable.Beautiful appearance: The surface of galvanized channel steel is smooth and bright, with good decorative effect. .

-

High Quality 20# Galvanized C Beam Steel Structural Steel C Channel

With the continuous improvement of urban construction and transportation network, galvanized channel steel has also been widely used in railways, highways, bridges and other projects. Its excellent anti-corrosion, pressure resistance and wear resistance provide a strong guarantee for the safety and long-term durability of transportation facilities.

-

Q355 Galvanized Carbon Hot Rolled U Beam Steel C Channel U Shaped Steel Channel

Galvanized channel steel made in China is widely used in structural support of houses, stair handrails, ventilation ducts, ceilings, etc. Its excellent corrosion resistance, stable quality and simple construction make it an indispensable material in construction projects.

-

Q235B Galvanized Channel Steel Low Alloy U-Shape Steel Construction Project Steel Structure Profile Light Steel Channel Steel

Among various coating methods for protecting steel substrates, hot dip galvanizing is an excellent one. It is when zinc is in a liquid state, and after a very complex physical and chemical reaction, the steel is not only plated with a thicker layer of pure zinc, but also a zinc-iron alloy layer is formed. This plating method not only has the corrosion resistance characteristics of electroplated zinc, but also has a zinc-iron alloy layer. It also has strong corrosion resistance that cannot be compared with electroplated zinc. Therefore, this plating method is particularly suitable for various strong corrosive environments such as strong acid and alkali mist.

-

Hot Selling Stainless Q215 Carbon Galvanized U Beam Steel C Channel U Channel Price

Hot-dip galvanized channel steel can be divided into hot-dip galvanized channel steel and hot-blown galvanized channel steel according to different galvanizing processes. The rust-removed steel parts are immersed in molten zinc liquid at about 440~460°C to make the steel A zinc layer is attached to the surface of the component to prevent corrosion.

-

Galvanized Structural U Beam Profile St37 C Steel Channel

Galvanized channel steel has the following characteristics:

1. Good corrosion resistance: The surface of galvanized channel steel is covered with a layer of zinc, which can effectively prevent corrosion by moisture, oxygen, carbon dioxide and other chemical substances, greatly extending the service life of galvanized channel steel.

2. Good plasticity: Galvanized channel steel has good plasticity and can be easily processed into profiles of various specifications. It can also be used for deep processing such as bending, cutting, and punching.

3. High strength: Galvanized channel steel has high strength and good load-bearing capacity. It is usually used in situations where it can withstand huge pressure.

4. Good wear resistance: The surface hardness of galvanized channel steel is high, which can effectively resist friction, wear, scratches and other external damage, and has a long service life.

5. Good corrosion resistance: Since the surface of galvanized channel steel is covered with a layer of zinc, it can avoid direct contact of the steel with corrosive media such as atmosphere and water, thereby improving the corrosion resistance of the steel. -

Ss400 Galvanized U Channel Steel Channel

Galvanized channel steel is a type of steel made from cold-rolled strip steel. Galvanized channel steel is usually rectangular or trapezoidal in cross-section. Because of its excellent anti-corrosion properties and high strength, it can be widely used in construction, ships, automobiles, bridges, machinery manufacturing and other fields. The specific uses are as follows:

-

Hot Dip Q235 Galvanized Steel Metal Beam Highway Guardrail Crash Barrier

A metal barrier is any type of physical structure or barricade made of metal designed to prevent or control access to a particular area or property. Some common types of metal barriers include:Fence, Bollards, Guardrails

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

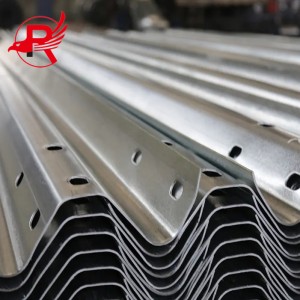

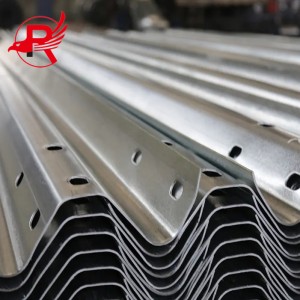

High Quality Crash Barrier Corrugated W Beam Guardrail for Sale

A metal barrier is any type of physical structure or barricade made of metal designed to prevent or control access to a particular area or property. Some common types of metal barriers include:Fence, Bollards, Guardrails

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur