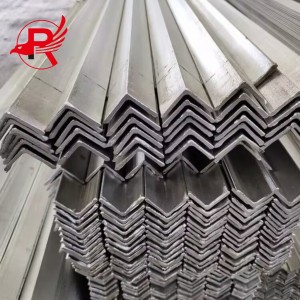

Factory Price 40x40x4mm Q235B Galvanized Angle Steel For Structure L Shape Angle Bar

In general, Angle Steel Bar, as an important construction steel, has a wide range of application prospects and market prospects. With the continuous progress of science and technology and the constant change of market demand, the production process and performance of galvanized Angle steel will continue to be improved and improved.

1, low treatment costs: the cost of hot dip Carbon Steel Angle Bar prevention is lower than the cost of other paint coatings;

2, durable: hot-dip galvanized Angle steel has the characteristics of surface luster, uniform zinc layer, no leakage plating, no drip, strong adhesion, strong corrosion resistance, in the suburban environment, the standard hot-dip galvanized rust prevention thickness can be maintained for more than 50 years without repair; In urban or offshore areas, the standard hot-dip galvanized anti-rust layer can be maintained for 20 years without repair;

3, good reliability: galvanized steel angle bar and steel is metallurgical combination, become a part of the steel surface, so the durability of the coating is more reliable;

4, the toughness of the coating is strong: the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use;

5, comprehensive protection: every part of the plating can be plated with zinc, even in the depression, sharp corners and hidden places can be fully protected;

6, save time and effort: the galvanizing process is faster than other coating construction methods, and the time required for painting on the site after installation can be avoided.

In the bending link, the bending machine can be used to bend the steel to the required Angle; In the welding process, the steel can be welded into the required structure by arc welding or gas shielded welding.

| Product name | Angle Bar |

| Grade | Q235B, SS400, ST37, SS41, A36 etc |

| Type | GB Standard, European Standard |

| Length | Standard 6m and 12m or as customer requirement |

| Technique | Hot Rolled |

| Application | Wide used in curtain wall materials, shelf construction, railways etc. |

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.