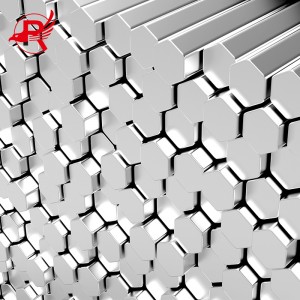

201 304 304L 316 316L 2205 2507 310S 316Ti Stainless Steel Bars

|

Product name |

Stainless Steel bar |

|

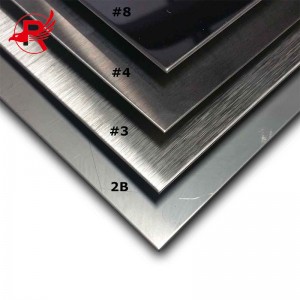

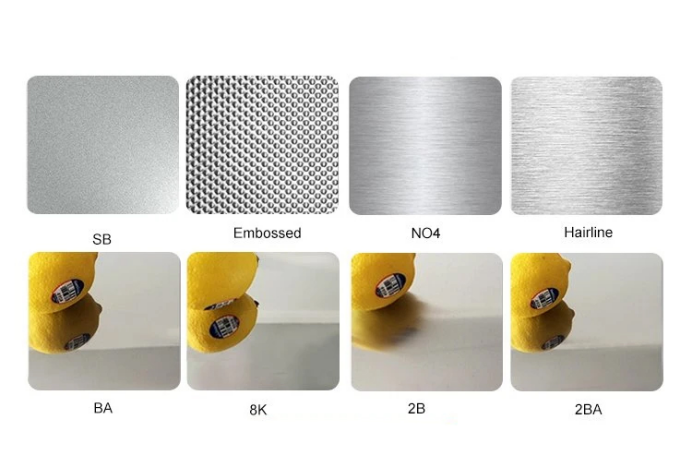

Surface |

2B, 2D, No.1, No.4, BA, HL, 6K, 8K ,etc |

|

Standard |

ASTM, AISI, DIN, EN, GB, JIS, etc |

|

Specifications

|

Diameter: 1-1500 mm |

| Length: 1m or as Customized | |

|

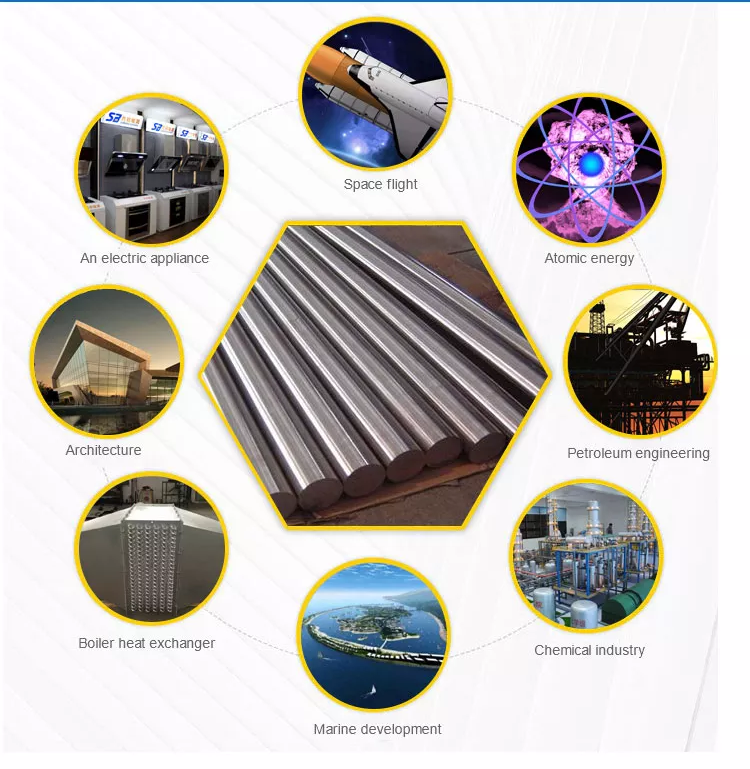

Applications |

Petroleum, electronics, chemical industry, medicine, light textile, food, machinery, construction, nuclear power,

aerospace,military and other industries |

|

Advantages

|

High-quality surface, clean, smooth; |

| Good corrosion resistance and durability | |

| Good welding performance, etc | |

|

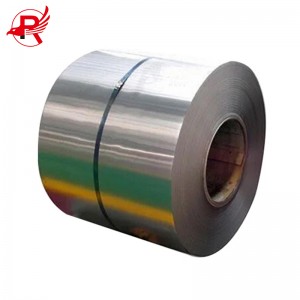

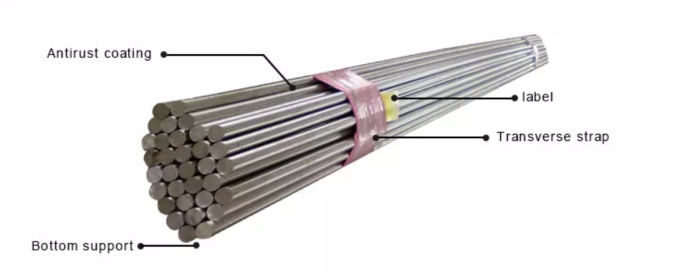

Package |

Standard seaworthy packing(plastic&wooden) or according to customers' requests |

|

Payment |

T/T, L/C 30%deposit+70% Balance |

|

Product name |

Stainless Steel bar |

|

Surface |

2B, 2D, No.1, No.4, BA, HL, 6K, 8K ,etc |

|

Standard |

ASTM, AISI, DIN, EN, GB, JIS, etc |

|

Specifications |

Diameter: 1-1500 mm |

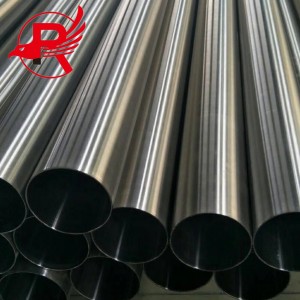

Stainless steel rods have broad application prospects and are widely used in hardware kitchen utensils, shipbuilding, petrochemical, machinery, medicine, food, electric power, energy, construction and decoration, nuclear power, aerospace, military and other industries!. Equipment used in seawater, chemical, dye, paper, oxalic acid, fertilizer and other production equipment; food industry, facilities in coastal areas, ropes, CD rods, bolts, nuts.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The chemical components of stainless steel bar is summarized in the following table:

|

Stainless Steel Round Bar(2-3Cr13 、1Cr18Ni9Ti) |

|||

|

Diameter mm |

weight (kg/m) |

Diameter mm |

weight (kg/m) |

|

8 |

0.399 |

65 |

26.322 |

|

10 |

0.623 |

70 |

30.527 |

|

12 |

0.897 |

75 |

35.044 |

|

14 |

1.221 |

80 |

39.827 |

|

16 |

1.595 |

85 |

45.012 |

|

18 |

2.019 |

90 |

50.463 |

|

20 |

2.492 |

95 |

56.226 |

|

22 |

3.015 |

100 |

62.300 |

|

25 |

3.894 |

105 |

68.686 |

|

28 |

4.884 |

110 |

75.383 |

|

30 |

5.607 |

120 |

89.712 |

|

32 |

6.380 |

130 |

105.287 |

|

35 |

7.632 |

140 |

122.108 |

|

36 |

8.074 |

150 |

140.175 |

|

38 |

8.996 |

160 |

159.488 |

|

40 |

9.968 |

170 |

180.047 |

|

42 |

10.990 |

180 |

201.852 |

|

45 |

12.616 |

200 |

249.200 |

|

50 |

15.575 |

220 |

301.532 |

|

55 |

18.846 |

250 |

389.395 |

Through different processing methods of cold rolling and surface reprocessing after rolling, the surface finish of stainless steel bars can have different types.

There are six kinds of stainless steel surface treatment, respectively mirror treatment, sandblasting treatment, chemical treatment, surface coloring, surface drawing treatment, spraying.

1 mirror processing: the outer layer of stainless steel polishing, can be divided into physical and chemical two methods, can also do local polishing in the surface, so that it can make stainless steel more concise high-grade, fashion advanced.

2. Sandblasting treatment: mainly using the force of air compression, high-speed spray material to be applied to the outer layer, it can make the shape of the outer layer change.

3. Chemical treatment: It is mainly used with chemistry and electricity, so that the outer layer of stainless steel forms a layer of stable compounds, like the most common electroplating is the type of chemical treatment.

4 surface coloring: through coloring technology to change the color of stainless steel, make the color more diverse, and not only can increase the color, but also can make it wear resistance, corrosion resistance become good.

5. Surface drawing treatment: It is a very common decorative technique in our daily life. It can form a lot of patterns, such as threads, ripples and spiral patterns.

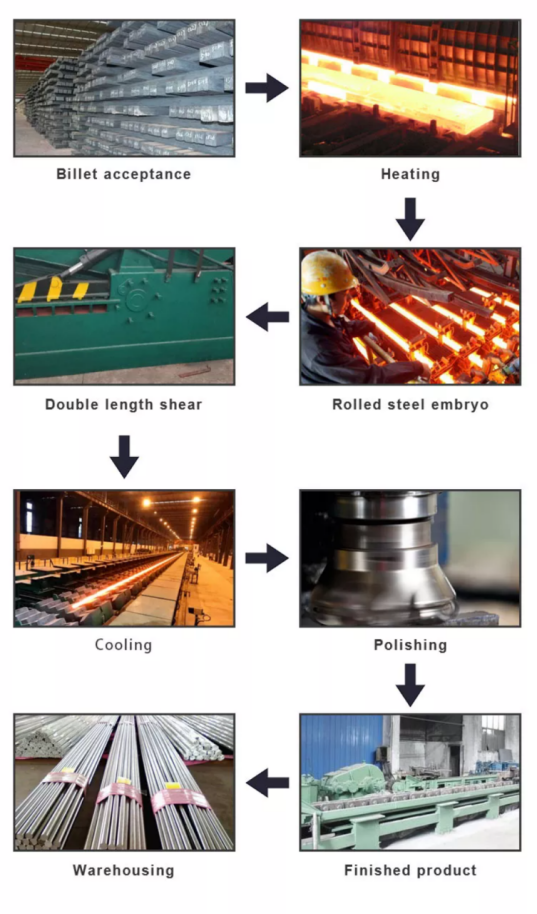

the standard sea packaging of stainless steel bar

Standard export sea packaging:

Woven Bag + Binding + Wooden Case;

Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

Other special packaging will be designed as customer’s request;

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.