-

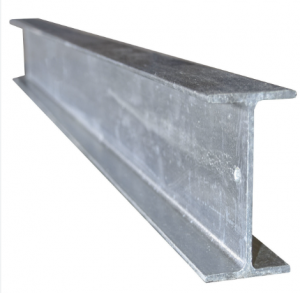

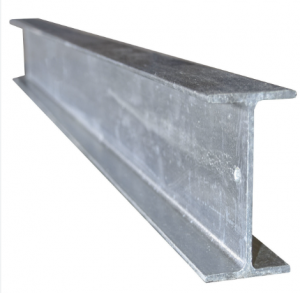

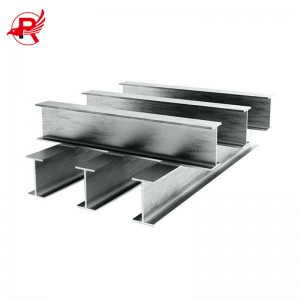

Large Stock 254*146 Cold Rolled ASTM A36 IPE Flange Profile Galvanised Steel I Beam

Galvanized I-beam is a kind of steel used in construction. Hot-dip galvanizing refers to a surface anti-corrosion process made by immersing high-quality low-carbon structural steel or low-alloy structural steel in molten zinc at about 500°C. Due to the advantages of low cost, convenient construction and good durability, it is widely used in the field of construction steel structure engineering.

-

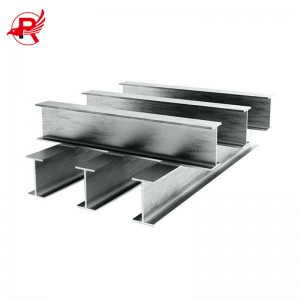

Cold Rolled ST37 Galvanised Steel H HEA Beam Zinc Coating

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

GI Pipe Galvanized Steel Pipe Galvanized Tube For Greenhouse Frame

Galvanized seamless pipes is a galvanized steel pipe. Its main feature is to form a layer of zinc on the surface of the steel pipe to improve the corrosion resistance of the steel pipe. The production process of galvanized pipe is usually to immerse the steel pipe in molten zinc so that its surface is evenly covered with a layer of zinc. This treatment method makes the galvanized pipe have better corrosion resistance and can be used for a long time in humid and corrosive environments.

-

Hot Dipped Galvanized Steel Pipe

Galvanized seamless pipes are an essential component in various industries such as construction, infrastructure, and transportation. These pipes are created by coating them with a protective layer of zinc, making them highly resistant to corrosion and suitable for outdoor applications. If you’re searching for high-quality galvanized seamless pipes, it’s crucial to choose reputable galvanized pipes manufacturers. With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients. We will support you well along the whole process with our professional knowledge and prime quality goods. Stock Sample is Free & Avaliable! Welcome your inquiry!

-

Greenhouse Pre Galvanized Round Steel Pipe/Tube

Galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

-

Factory Direct Supply Greenhouse Pre Galvanized Round Steel Pipe/Tube

Galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

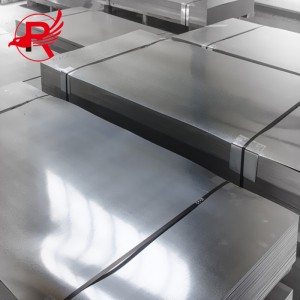

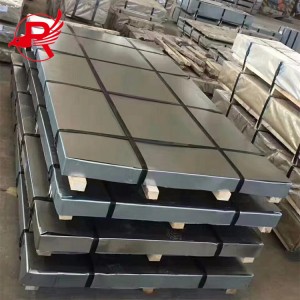

Astm A36 S335 3mm Thick Hot Dip Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets to improve the corrosion resistance of the steel sheets. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance.

Galvanized sheets are widely used in construction, furniture, automobile manufacturing, electricity, communications and other fields. In the construction field, galvanized sheets are often used to make roofs, walls, pipes, doors and windows, etc., because their corrosion resistance can effectively extend their service life. In furniture manufacturing, galvanized sheets can be used to make the metal frame and shell of furniture to improve the durability of the product. In automobile manufacturing, galvanized sheets can be used in the manufacture of automobile body panels to improve the durability of the automobile. In the fields of power and communications, galvanized sheets can be used to make cable sheaths, communication equipment casings, etc., because their corrosion resistance can ensure the safe operation of equipment.

In general, galvanized sheets have become one of the indispensable materials in various industrial fields due to their excellent corrosion resistance and wide range of applications.

-

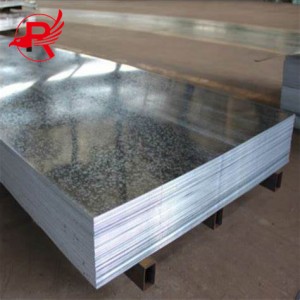

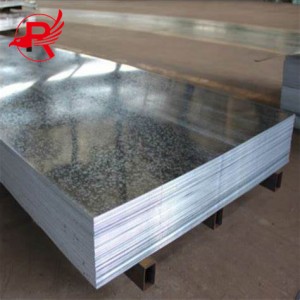

ASTM A653M-06a Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets. The purpose of galvanizing is to improve the corrosion resistance of steel plates, because zinc has good anti-corrosion properties. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance. The production process of galvanized sheets includes multiple steps such as raw material preparation, smelting zinc liquid, hot-dip galvanizing, and surface treatment. The characteristics of galvanized sheets include excellent corrosion resistance, wear resistance, good processing performance, smooth and beautiful surface, and good electrical conductivity. Galvanized sheets are widely used in construction, machinery, electricity, communications and other fields, and are often used in building structures, drainage systems, industrial equipment, agricultural machinery, transportation and other fields. Its corrosion resistance makes it one of the indispensable materials in various industries.

-

High Quality Building Materials 0.12-4.0mm SPCC Cold Rolled Galvanized Steel Sheet

Galvanized sheet is a product that is coated with a layer of zinc on the surface of ordinary steel sheets. The purpose of galvanizing is to improve the corrosion resistance of steel plates, because zinc has good anti-corrosion properties. Galvanized sheets usually use a hot-dip galvanizing process, which involves immersing the steel sheet in molten zinc liquid to form a uniform and dense zinc layer. This treatment gives galvanized sheets excellent corrosion resistance, wear resistance and weather resistance. The production process of galvanized sheets includes multiple steps such as raw material preparation, smelting zinc liquid, hot-dip galvanizing, and surface treatment. The characteristics of galvanized sheets include excellent corrosion resistance, wear resistance, good processing performance, smooth and beautiful surface, and good electrical conductivity. Galvanized sheets are widely used in construction, machinery, electricity, communications and other fields, and are often used in building structures, drainage systems, industrial equipment, agricultural machinery, transportation and other fields. Its corrosion resistance makes it one of the indispensable materials in various industries.

-

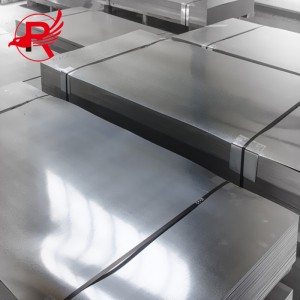

High Quality Dx51d Galvanized Steel Plate Price

The zinc layer of Galvanized sheet refers to a layer of zinc coating formed on the surface of ordinary steel sheets. The formation of this layer of zinc coating is achieved through the hot-dip galvanizing process, which involves immersing the steel plate in molten zinc liquid so that the surface of the steel plate is evenly covered with a layer of zinc. This zinc layer is dense and uniform, and can effectively block the erosion of the steel plate by atmosphere, water and chemical substances, thus improving the corrosion resistance of the steel plate. The zinc layer also has good wear resistance and can protect the surface of the steel plate from friction and wear. In addition, the zinc layer also provides good weather resistance and can maintain stable performance under harsh climate conditions. In addition, the formation of the zinc layer also makes the galvanized sheet have good processing performance, and can be processed by bending, stamping, welding, etc., and is suitable for the manufacturing of various complex shapes. In general, the zinc layer of galvanized sheets is the key to its excellent corrosion resistance, wear resistance, weather resistance and other characteristics, making galvanized sheets widely used in construction, machinery, electricity, communications and other fields.

-

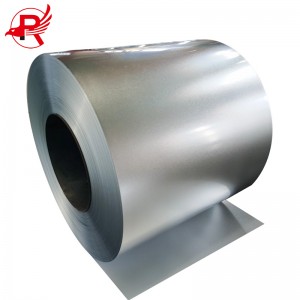

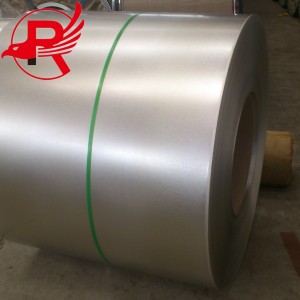

ASTIM A792 G550 Aluzinc GL Galvalume Steel Coil

aluminum zinc plated steel coil is a product made of cold-rolled low-carbon steel coil as the base material and hot-dip aluminum-zinc alloy coating. Galvalume coils have excellent corrosion resistance and weather resistance and are widely used in construction, home appliances, transportation and other fields.

The coating of galvalume coils is mainly composed of aluminum, zinc and silicon, forming a dense oxide layer, which effectively blocks oxygen, water and carbon dioxide in the atmosphere and provides good anti-corrosion protection. At the same time, galvanized coils also have excellent heat reflection properties and high temperature resistance, which can effectively reduce the energy consumption of buildings and extend their service life.

In the construction field, galvanized coils are often used in roofs, walls, rainwater systems and other parts to provide beautiful and durable protection. In the field of home appliances, galvanized coils are often used to make the casings of refrigerators, air conditioners and other products, with good decorative effects and corrosion resistance. In the field of transportation, galvanized coils are often used to make vehicle shells, body parts, etc., providing lightweight and high-strength protection.

In short, galvalume coils have become an ideal choice in many fields with their excellent anti-corrosion properties, weather resistance and decorative properties.

-

High Quality Hdgi Galvalume Steel Coil Z40-275

aluminum zinc plated steel coil is a product made of cold-rolled low-carbon steel coil as the base material and hot-dip aluminum-zinc alloy coating. This coating is mainly composed of aluminum, zinc and silicon, forming a dense oxide layer that effectively blocks oxygen, water and carbon dioxide in the atmosphere and provides good anti-corrosion protection. Galvalume coil has excellent corrosion resistance, weather resistance and heat reflection properties, and is suitable for use in a variety of environmental conditions. It also has high strength and plasticity and is easy to be processed into various shapes, so it is widely used in construction, home appliances, transportation and other fields. In short, galvalume coil has become an important metal material with its excellent anti-corrosion performance and diversified application fields.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur