-

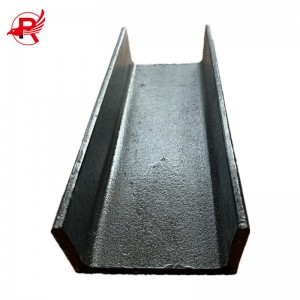

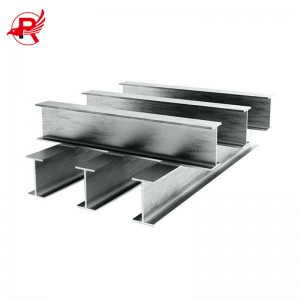

Steel Manufacturer Q235B Q355B C Profile Galvanised Steel U Channel

Plated U-shaped steel, a kind of galvanized steel, is characterized by its shape, like the English capital letter U, so it is named “U-shaped steel”.

U-shaped steel is processed by hot coil and cold bending. It has thin wall, light weight, excellent section performance and high strength. Compared with traditional channel steel, it can save 30% of materials with the same strength.

-

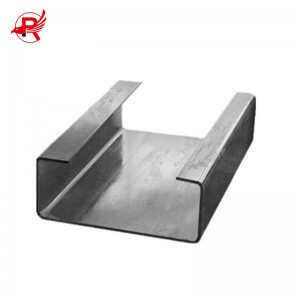

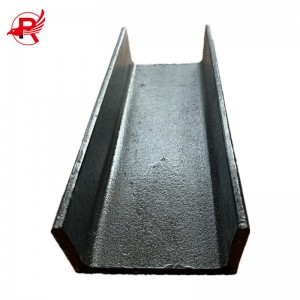

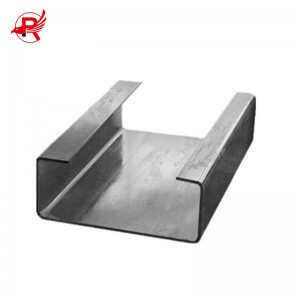

Hot Sale High quality New Design Galvanized C Steel Channel Profile

Galvanized C-shaped steel is a new type of steel made of high-strength steel plate, then cold-bent and roll-formed. Compared with traditional hot-rolled steel, the same strength can save 30% of the material. When making it, the given C-shaped steel size is used. C-shaped steel The forming machine automatically processes and forms.

Compared with ordinary U-shaped steel, galvanized C-shaped steel can not only be preserved for a long time without changing its material, but also has relatively strong corrosion resistance, but its weight is also slightly heavier than the accompanying C-shaped steel. It also has a uniform zinc layer, smooth surface, strong adhesion, and high dimensional accuracy. All surfaces are covered by a zinc layer, and the zinc content on the surface is usually 120-275g/㎡, which can be said to be a super protective one. -

Manufacture Cold Rolled Galvanized C Channel Steel

Galvanized C-shaped steel is a new type of steel made of high-strength steel plate, then cold-bent and roll-formed. Compared with traditional hot-rolled steel, the same strength can save 30% of the material. When making it, the given C-shaped steel size is used. C-shaped steel The forming machine automatically processes and forms.

Compared with ordinary U-shaped steel, galvanized C-shaped steel can not only be preserved for a long time without changing its material, but also has relatively strong corrosion resistance, but its weight is also slightly heavier than the accompanying C-shaped steel. It also has a uniform zinc layer, smooth surface, strong adhesion, and high dimensional accuracy. All surfaces are covered by a zinc layer, and the zinc content on the surface is usually 120-275g/㎡, which can be said to be a super protective one. -

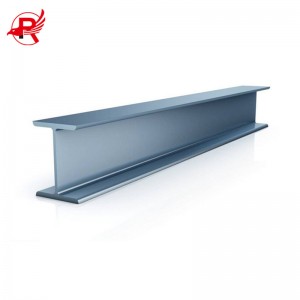

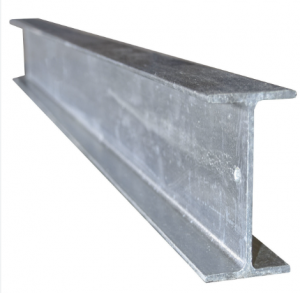

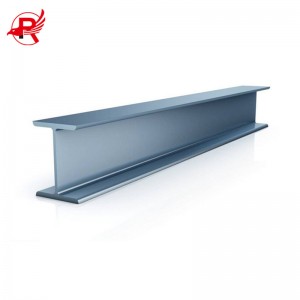

High Grade Q345B Carbon Steel Welded Galvanized Carbon Steel H Beam

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

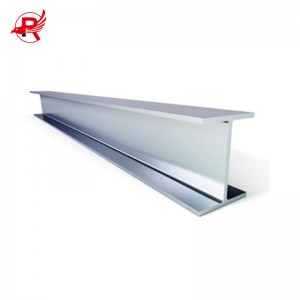

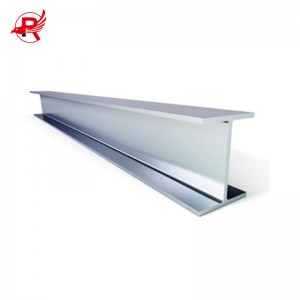

High Quality W14 W16 W12 W21 H Section Galvanized Steel H Shape Beam

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

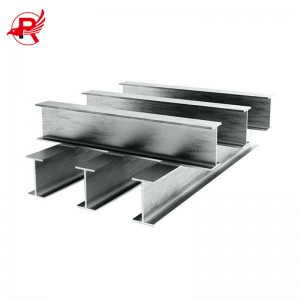

Cold Rolled Galvanised Steel H HEA Beam Zinc Coating

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

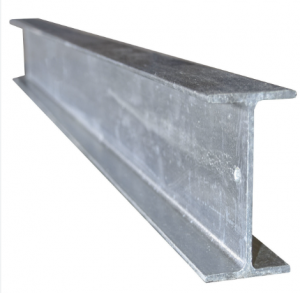

Large Stock 254*146 Cold Rolled A36 S235 IPE Flange Profile Galvanised Steel I Beam

Galvanized I-beam is a kind of steel used in construction. Hot-dip galvanizing refers to a surface anti-corrosion process made by immersing high-quality low-carbon structural steel or low-alloy structural steel in molten zinc at about 500°C. Due to the advantages of low cost, convenient construction and good durability, it is widely used in the field of construction steel structure engineering.

-

SPCC DC01 DC02 DC03 Cold-Rolled CR Carbon Steel Sheets for Corrugated Roofing

Cold rolled sheet is a product made of hot rolled coil rolled under the recrystallization temperature at room temperature. It is widely used in automobile manufacturing and electrical products. Cold rolling is rolling at recrystallization temperature, but is generally understood as rolling using normal temperature rolled materials.