-

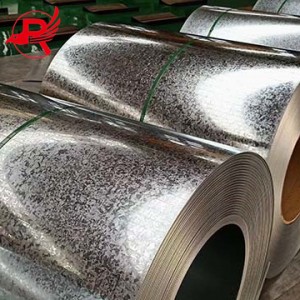

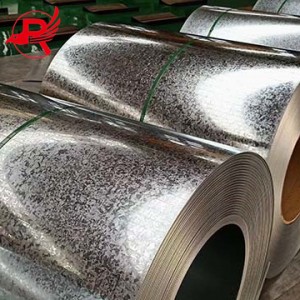

Big Spangle Galvanized Cold Rolled Q235 Carbon Steel Coil Suppliers

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

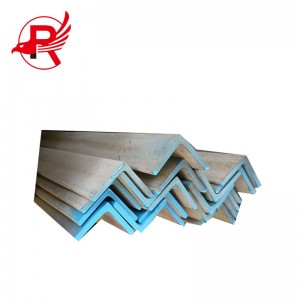

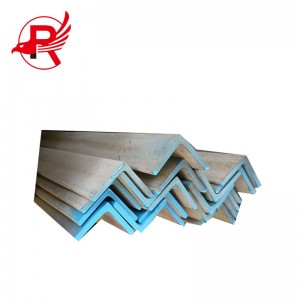

China Factory Hot Rolled Mild Carbon Galvanized Steel Angle Bar for Construction

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold-dip galvanized angle steel. Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. The cold-dip galvanized coating mainly ensures the full contact between the zinc powder and the steel through the electrochemical principle, and generates an electrode potential difference for anti-corrosion.

-

Hot Dipped Galvanized GI Hot Rolled Equal Steel Angle Bar

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold-dip galvanized angle steel. Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. The cold-dip galvanized coating mainly ensures the full contact between the zinc powder and the steel through the electrochemical principle, and generates an electrode potential difference for anti-corrosion.

-

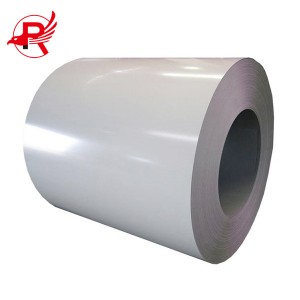

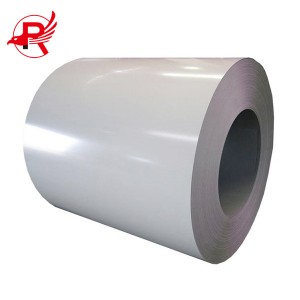

Dx51D Dx52D Dx53D RAL9003 0.6mm Hot Rolled Prepainted PPGI Color Coated Galvanized Steel Coil For Sale

PPGI is made of hot galvanized steel sheet and hot dipped aluminum zinc plate as substrate.After the surface pre treatment,they will be covered a layer or layers of organic coating ,then baking and curing to production.Have also been coated with a variety of different colors of organic coating color steel plate, referred to as “painted coil” .They are mainly used in both inside and outside the building materials, house hold appliances and other fields.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

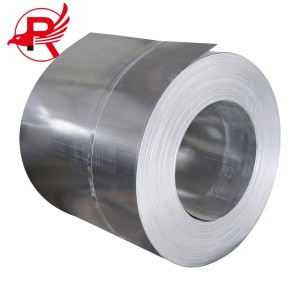

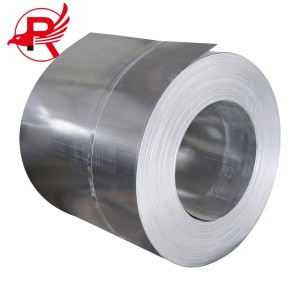

Hot Dipped Dx51d Dx52d Z275 Cold Rolled Galvanized GI Carbon Steel Coil for Sales

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Cold Rolled Galvanized / Galvanised Steel Coils for PPGI

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

DX51D Z275 Z350 Hot Dipped Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Hot Sales DX51D Z275 Zinc Coated Cold Rolled Hot Dipped Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Cold Rolled DX51 Hot Dipped Galvanized Steel GI Coil Prices

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Factory Hot Dipped Cold Rolled JIS ASTM DX51D SGCC Galvanized Steel Coil

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

-

Hot Sales DX51D Z275 Zinc Coated Cold Rolled Hot Dipped Galvanized Steel Coil for Building

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

Construction Material High Quality Hot Dipped Galvanized Steel Coils z275

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!