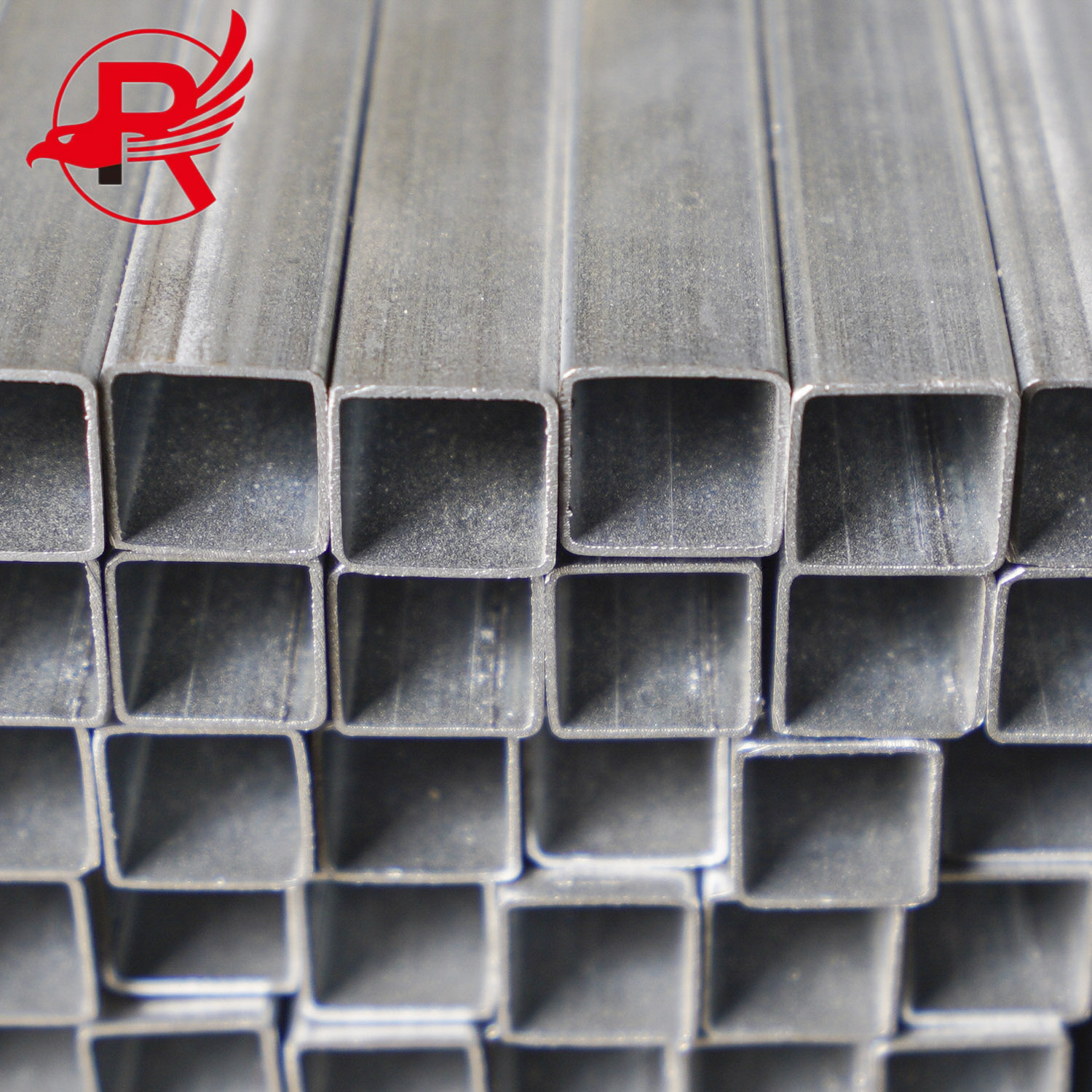

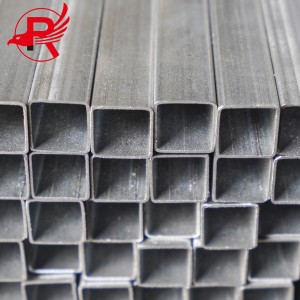

Factory Best Quality Hot Sale Hot-dipped Galvanized Square Rectangular Steel Pipes

Galvanized square steel pipes offer enhanced protection and corrosion resistance. Their entire structure is composed of zinc, forming dense quaternary crystals that form a barrier on the steel plate, effectively preventing corrosion from penetrating. This corrosion resistance stems from the zinc's strong barrier layer. When zinc acts as a sacrificial barrier on cut edges, scratches, and plating abrasions, it forms an insoluble oxide layer, fulfilling its barrier function.

Hot-dip galvanized square carbon pipes are made by welding steel sheets or strips that have been rolled into a square tube. These square tubes are then placed in a hot-dip galvanizing bath and undergo a series of chemical reactions to form a new square tube. The production process for hot-dip galvanized square tubes is relatively simple, yet highly efficient. Available in a wide variety of sizes, these tubes require minimal equipment and capital, making them suitable for small galvanized square tube manufacturers.

Because galvanized square pipe is galvanized on the square pipe, so the application range of galvanized square pipe has been greatly expanded than square pipe.

Building and Structure Applications: Used in building frames, fences, stair railings, and more, providing stable support and durable protection.

Machinery and Equipment: Used in manufacturing machinery supports and structural components, suitable for high-intensity operating environments.

Furniture and Decoration: Widely used in table and chair frames, shelves, decorative brackets, and more, combining durability and aesthetics.

Transportation Facilities: Suitable for guardrails, streetlight poles, and parking lot fences, providing long-term protection against the effects of harsh weather.

Advertising Applications: Suitable for billboards and sign frames, ensuring structural stability and resisting rust and deformation.

Door Frames and Railings: Widely used in door frames, balcony railings, and fence guardrails, ensuring stability and safety, suitable for residential and commercial buildings.

|

Product Name

|

Galvanized Square Rectangular Steel Pipe

|

|||

|

Zinc Coating

|

30g-550g ,G30,G60, G90

|

|||

|

Wall Thickness

|

1-5MM

|

|||

|

Surface

|

Pre-galvanized, Hot dipped galvanized, Electro galvanized, Black, Painted, Threaded, Engraved, Socket.

|

|||

|

Grade

|

Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D

|

|||

|

Tolerance

|

±1%

|

|||

|

Oiled or Non-Oiled

|

Non-Oiled

|

|||

|

Delivery Time

|

3-15 days (according to the actual tonnage) | |||

|

Usage

|

Civil engineering, architecture, steel towers, shipyard, scaffoldings, struts, piles for suppression of landslide and other

structures |

|||

|

Length

|

Fixed or random, according to customer's requirements

|

|||

|

Processing

|

Plain weave (can be threaded, punched, shrunk, stretched...)

|

|||

|

Package

|

In bundles with steel strip or in loose, non-woven fabrics packings or as per customers' request

|

|||

|

Payment Term

|

T/T

|

|||

|

Trade Term

|

FOB,CFR,CIF ,DDP,EXW

|

|||

| GB | Q195/Q215/Q235/Q345 |

| ASTM | ASTM A53/ASTM A500/ASTM A106 |

| EN | S235JR/S355JR/EN 10210-1/EN 39/EN 1123-1:1999 |

| Grade | Chemical Composition | Mechanical properties | ||||||

| C | Mn | Si | S | P | surrender | stretch | Longati | |

| strength-Mpa | strength-Mpa | percentage | ||||||

| Q195 | 0.06-0.12 | 0.25-0.50 | ≤0.30 | ≤0.045 | ≤0.05 | ≥195 | 315-430 | ≥33 |

| Q235 | 0.12-0.20 | 0.30-0.67 | ≤0.30 | ≤0.045 | ≤0.04 | ≥235 | 375-500 | ≥26 |

| Q345 | ≤0.20 | 1.00-1.60 | ≤0.55 | ≤0.04 | ≤0.04 | ≥345 | 470-630 | ≥22 |

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.