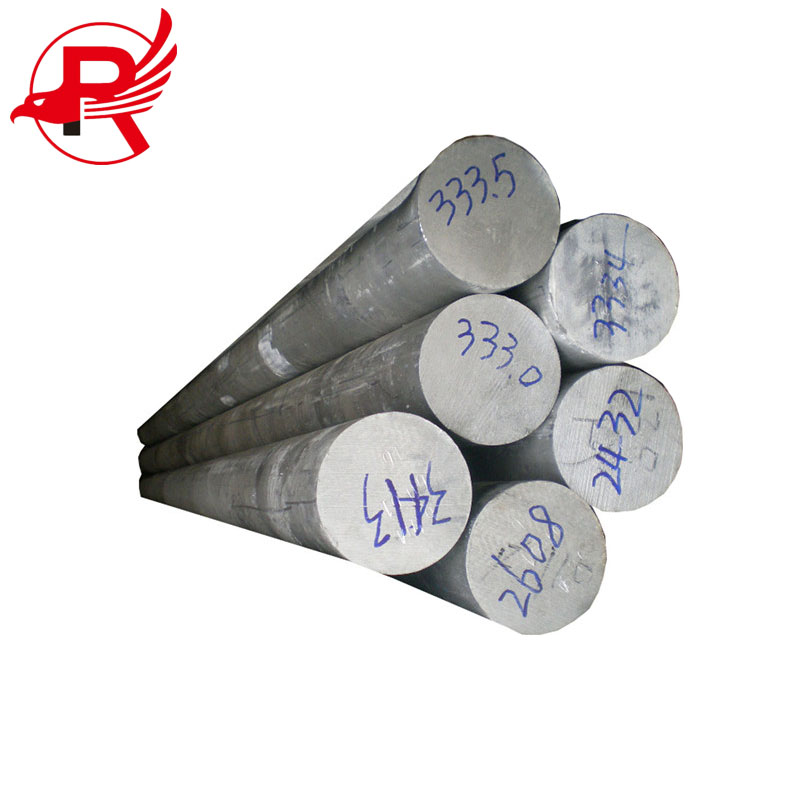

China Factory 5083 Aluminum Rod Bar

|

Product Name |

ASTM B211,ASTM B221, ASTM B531 ETC | |

|

Material |

Aluminum, aluminum alloy 3003 aluminum bar2000 Series: 2014A, 2014, 2017, 2024, 2219, 2017, 2017A, 2218

5000 Series: 5052, 5056, 5154, 5015, 5082, 5754, 5456, 5086, 5182 6000 Series: 6061, 6060, 6063, 6070, 6181, 6082 7000 Series: 7005, 7020, 7022, 7050, 7075 8000 Series: 8011, 8090 |

|

|

Processing |

Extrusion | |

|

Shape |

Round, Square, Hex, etc. | |

|

Size |

Diameter (mm) | Length (mm) |

| 5mm-50mm | 1000mm-6000mm | |

| 50mm-650mm | 500mm-6000mm | |

|

Packing |

Standard export packingPlastic bag or waterproof paper

Wooden case (custom suffocating free) Pallet |

|

|

Property |

Aluminum has a special chemical physical characteristic, not only light weight, firm texture, but have good ductility, electrical conductivity, thermal conductivity, heat resistance and radiation | |

Aluminum rod is a common metal material, usually made of high-purity aluminum alloy. Aluminum rods come in a variety of specifications and sizes and can be customized according to different needs. During production and use, some details need to be paid attention to.

First of all, for the storage and transportation of aluminum rods, collisions and friction should be avoided to avoid damaging the surface. When handling and stacking, handle with care to avoid deformation or damage caused by excessive force.

Secondly, for the processing and use of aluminum rods, appropriate tools and methods should be selected. During cutting, drilling, welding and other processing processes, appropriate tools and processes should be used to avoid damage to the aluminum rods. During use, contact with chemicals such as acids and alkalis should be avoided to avoid affecting the surface quality of the aluminum rod.

In addition, for the cleaning and maintenance of aluminum rods, dirt and impurities on the surface should be removed regularly to maintain their good appearance and performance. You can use detergent and a soft cloth to clean, avoid using hard objects to scratch the surface.

Finally, care should be taken to avoid use in high temperature environments to avoid affecting the performance of the aluminum rods. In high-temperature environments, the strength and hardness of aluminum rods may change, so selection and use need to be based on specific conditions.

Overall, proper storage, processing, cleaning and maintenance are key to ensuring the long-term stable performance of aluminum rods. Reasonable use and maintenance can extend the service life of aluminum rods and ensure their application results in various fields.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Process of production

The production process of martensitic stainless steel is as follows: hot rolling roil - annealing - alkali immersion - rinsing - pickling - coating - wire drawing - decoating - finished product inspection - packaging

Austenitic stainless steel wire production process: hot rolling coil - solution treatment - alkali immersion - rinsing - pickling - coating - wire drawing - decoating - neutralization - finished product inspection - packaging

product Inspection

aluminum alloy bar is a commonly used manufacturing material and is widely used. In order to ensure the quality of aluminum products, it is necessary to test the quality of aluminum rods. Below we will introduce the quality inspection standards of aluminum rods.

1. Appearance requirements: aluminum round bar should have no cracks, bubbles, inclusions, defects and other defects. The surface should be flat, with a good finish and no obvious scratches allowed.

2. Size requirements: the diameter, length, curvature and other dimensions of the aluminum rod should meet the standard. Diameter tolerance and length tolerance should not exceed the national standards.

3. Chemical composition requirements: The chemical composition of the aluminum rod should meet the standards stipulated by the state, and the standard chemical composition should be consistent with the chemical composition of the trust in the aluminum rod quality inspection certificate.

1. Appearance detection method: Place the aluminum rod under the light source and observe whether there are defects and scratches on the surface.

2. Size detection method: The diameter measuring instrument and the length measuring instrument are used to measure the aluminum rod. The measurement of curvature should be carried out on special testing equipment.

3. Chemical composition detection method: The method of chemical analysis is used to detect the aluminum rod.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.