Z Dimension Cold Formed Steel Sheet Pile

|

Product Name

|

sheet pile z type |

|

Technique

|

cold rolled / hot rolled

|

|

Shape

|

Z Type / L Type / S Type / Straight

|

|

Standard

|

GB/JIS/DIN/ASTM/AISI/EN ect.

|

|

Material

|

Q234B/Q345B

|

|

JIS A5523/ SYW295,JISA5528/SY295,SYW390,SY390 ect.

|

|

|

Application

|

Cofferdam /River flood diversion and control/

|

|

Water treatment system fence/Flood protection /Wall/

|

|

|

Protective embankment/Coastal berm/Tunnel cuts and tunnel bunkers/

|

|

|

Breakwater/Weir Wall/ Fixed slope/ Baffle wall

|

|

|

Length

|

6m,9m,12m,15m or customized

|

|

Max.24m

|

|

|

Diameter

|

406.4mm-2032.0mm

|

|

Thickness

|

6-25mm

|

|

Sample

|

Paid provided

|

|

Lead time

|

7 to 25 working days after the receipt of 30% deposit

|

|

Payment terms

|

30%TT for deposit, 70% balance before shipment

|

|

Packing

|

Standard export packing or according to customer's request

|

|

MOQ

|

1 Ton

|

|

Package

|

Bundled

|

|

Size

|

Customer's Requst

|

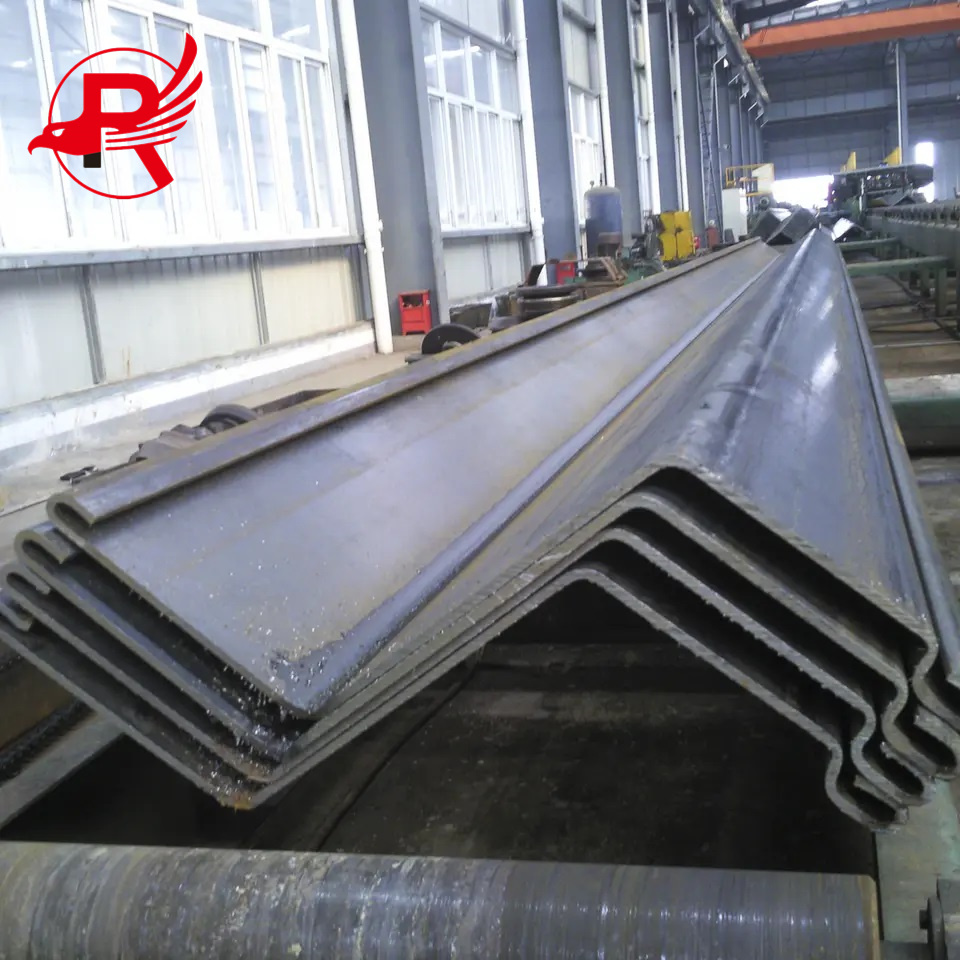

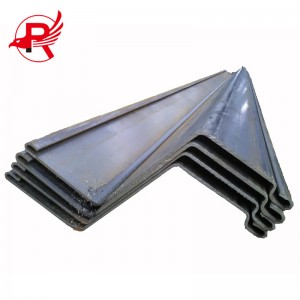

There are two types of cold-formed steel sheet piles: non-biting cold-formed steel sheet piles (also called channel plates) and biting cold-formed steel sheet piles (consisting of L-shaped, S-shaped, U-shaped and Z-shaped plates). Process: The thin plate (normal thickness 8mm ~ 14mm) is rolled and shaped continuously at the cold forming machine. Advantages: less investment of production line, lower cost of production, more flexible control of product size.Cons: the thickness of the pile is equal throughout, no optimization of the cross section is possible leading to increase in amount of steel used, it is difficult to control the shape of the lock part, the buckle is not strict, water could not stop and the pile is easily torn during the use.

Foundation Engineering: Ideal for deep excavation support, retaining walls, and foundation stabilization, ensuring robust and safe structures.

Marine Projects: Perfect for docks, bridges, and coastal protection, providing excellent durability in marine environments.

Water Conservancy: Supports dams, levees, and river regulation projects with reliable structural strength.

Railway Infrastructure: Efficiently reinforces embankments, tunnels, and bridge foundations, combining high strength with quick installation.

Mining Operations: Applied in mining areas and tailings storage facilities to stabilize slopes and foundations effectively.

Durable, strong, and versatile — Z-shaped steel sheet piles are the preferred solution for a wide range of construction projects.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Production line of Steel sheet pile rolling line

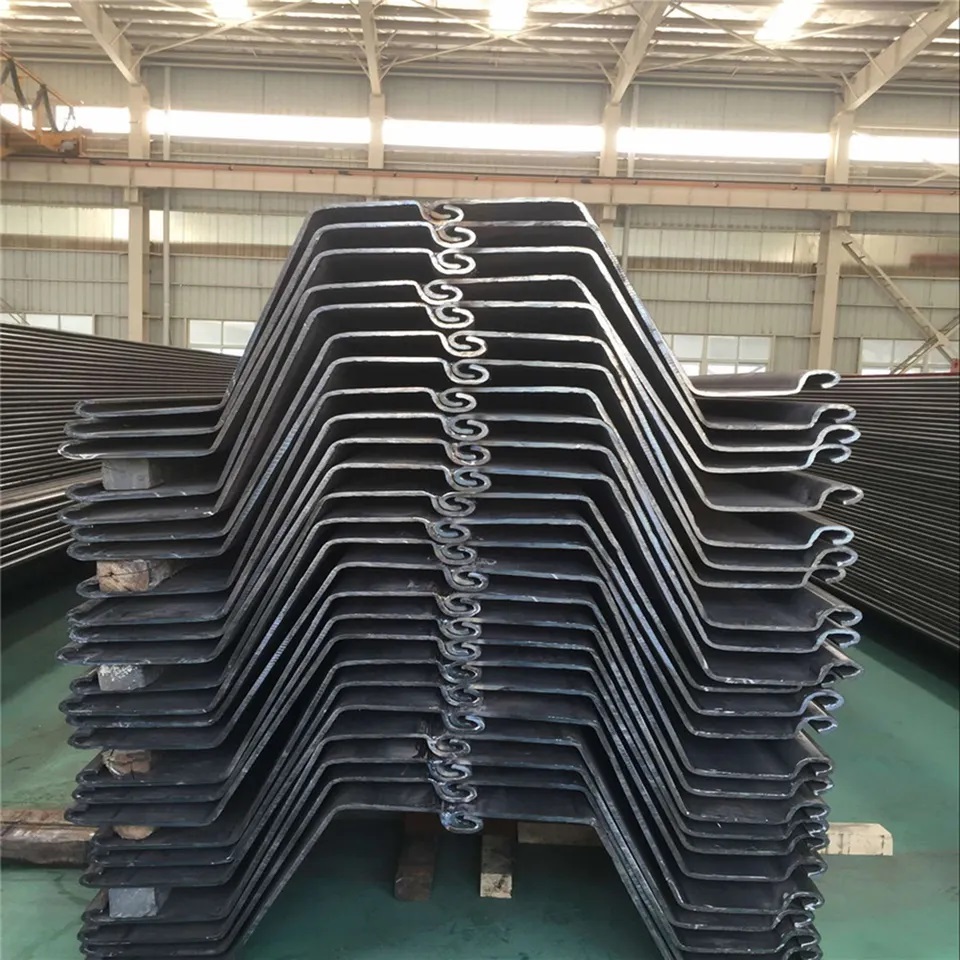

z shaped sheet pile production is a manufacturing process that involves the creation of Z-shaped steel sheets with interlocking edges. The process begins with the selection of high-quality steel and the cutting of the sheets to the required dimensions. The sheets are then shaped into the distinctive Z-shape using a series of rollers and bending machines. The edges are then interlocked to create a continuous wall of sheet pile. Quality control measures are put in place throughout the production process to ensure the final product meets the necessary standards.

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.