Q235 Q355 H Section Steel Structure for Heavy Duty Galvanized Workshop

Structural steel is a type of steel building structures material with a specific shape and chemical composition to suit the applicable project specifications.

Depending on the applicable specifications of each project, structural steel may come in a variety of shapes, sizes, and specifications. Some are hot-rolled or cold-rolled, while others are welded from flat or bent plates. Common structural steel shapes include I-beams, high-speed steel, channels, angles, and plates.

International Standards for steel Frame Structure

GB 50017 (China): Chinese national standard, covering design loads, construction details, durability, and safety requirements.

AISC (USA): North America's largest authoritative handbook, covering load standards, structural design, and connections.

BS 5950 (UK): Emphasizes a balance between safety, economy, and structural efficiency.

EN 1993 – Eurocode 3 (EU): A unified European design system for steel structures.

| Standard | National Standard | American Standard | European Standard | |

| Introduction | It takes national standards(GB) as the main part and industry standards as supplement, and highlights the overall control of design, construction and acceptance. | In the context of the ASTM material standards and AISC design specifications, we strive to harmonise market-based independent certifications with industry standards. | EN series of standards (European standards) | |

| Core Standards | Design standards | GB 50017-2017 | AISC(AISC 360-16) | EN 1993 |

| Material standards | GB/T 700-2006、GB/T 1591-2018 | ASTM Internationa | EN 10025 series developed by CEN | |

| Construction and acceptance standards | GB 50205-2020 | AWS D1.1 | EN 1011 series | |

| Industry-specific standards | For example, JT/T 722-2023 in the field of bridges, JGJ 99-2015 in the field of construction | |||

| Required Certificates | Steel structure engineering professional contracting qualification (Special Grade, Grade I, Grade II, Grade III) | AISC Certification | CE Mark, German DIN Certification, UK CARES Certification |

|

| Certificate of classification from the China Classification Society (CCS); Qualification certificate of the steel structure processing enterprise. | FRA certification | |||

| Property of the material, mechanical properties, quality of weld, etc. issued by the third party testing agency. | ASME | |||

|

Specifications:

|

|

|

Main Steel Frame

|

H-section steel beam and columns, painted or galvanized, galvanized C-section or steel pipe, etc.

|

|

Secondary Frame

|

hot dip galvanized C-purlin, steel bracing, tie bar, knee brace, edge cover, etc.

|

|

Roof Panel

|

EPS sandwich panel, glass fiber sandwich panel, Rockwool sandwich panel, and PU sandwich

panel or steel plate, etc. |

|

Wall Panel

|

sandwich panel or corrugated steel sheet, etc.

|

|

Tie Rod

|

circular steel tube

|

|

Brace

|

round bar

|

|

Knee Brace

|

angle steel

|

|

Drawings & Quotation:

|

|

|

(1) Customized design is welcomed.

|

|

|

(2) In order to give you an exact quotation and drawings, please let us know the length, width, eave height, and local weather. We

will quote for you promptly. |

|

Steel Structure Sections

Available sections are described in published standards worldwide, and specialized, proprietary sections are also available.

I-beams (capital "I" sections—in the UK, this includes universal beams (UB) and universal columns (UC); in Europe, this includes IPE, HE, HL, HD, and other sections; in the US, this includes wide flange (WF or W-shaped) and H-shaped sections)

Z-beams (reverse half-flanges)

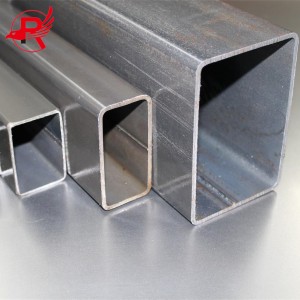

HSS (hollow structural sections, also known as SHS (structural hollow sections), including square, rectangular, circular (tubular), and oval sections)

Angles (L-shaped sections)

Structural channels, C-shaped sections, or "C" sections

T-beams (T-shaped sections)

Bars, which are rectangular in cross-section but not wide enough to be considered plate.

Rods, which are circular or square sections with a length relative to their width.

Plates, which are sheet metal thicker than 6 mm or 1⁄4 inch.

1.Construction Engineering

Industrial Buildings: Factories (machinery, metallurgy, chemical), warehouses (high-bay, cold storage)

Civil & Public Buildings: high-rises, stadiums, exhibition halls, theaters, airport terminals

Residential Buildings: Steel-structured housing

2. Transportation Infrastructure

Bridges: Long-span railway/highway bridges

Rail Transit: Vehicles and Stations

3. Special Engineering & Equipment

Marine & Shipbuilding: Off-shore platforms, ships

Machinery & Equipment: Industrial tanks, cranes, special vehicles, mechanical frames

4.Other Applications

Temporary buildings, large sopping mall domes, wind turbine towers, solar panel supports

Cutting Process

1. Preliminary Preparation

Material Inspection

Drawing Interpretation

2. Choosing the Appropriate Cutting Method

Flame Cutting: Suitable for thicker mild steel and low-alloy steel, ideal for rough machining.

Water Jet Cutting: Suitable for a variety of materials, especially heat-sensitive steel or high-precision, special-shaped parts.

Welding Processing

Through this process, heat, pressure or both (occasionally with the addition of filler material) is applied to cause atomic bonding at the interface of the steel components, resulting in a strong, monolithic structure. It is a crucial linking process in the fabrication of steel structures and has been extensively applied in buildings, bridges, machineries, shipbuilding and so on, bearing on the strength, stability and safety of the steel structure.

Based on the construction drawings or welding procedure qualification report (PQR), clearly define the weld joint type, groove dimensions, weld dimensions, welding position, and quality grade.

Punching Processing

This process involves mechanically or physically creating holes in steel structural components that meet design requirements. These holes are primarily used for connecting components, routing pipelines, and installing accessories. It is a crucial process in steel structure manufacturing to ensure component assembly accuracy and joint strength.

Based on the design drawings, specify the hole location (coordinate dimensions), number, diameter, accuracy level (e.g., ±1mm tolerance for standard bolt holes, ±0.5mm tolerance for high-strength bolt holes), and hole type (round, oblong, etc.). Use a marking tool (such as a steel tape measure, stylus, square, or sample punch) to mark the hole locations on the component surface. Use a sample punch to create locating points for critical holes to ensure accurate drilling locations.

A wide variety of surface treatment processes are available for steel structure building, effectively enhancing their corrosion and rust resistance, as well as their aesthetic appeal.

Hot-dip galvanizing: The old fashioned standby for rust resistance.

Powder coating: Colored powder for using outdoors or indoors for decorating.

Epoxy Coating Gems: Excellent corrosion resistance and good for aggressive environments.

Zinc-rich epoxy coating: High zinc content ensures long lasting electrochemical protection and high structural stability.

Spray painting: Versatile and affordable, serving diverse protective and decorative requirements.

Black oil coating: Cheap, and good enough for general rust protection work.

Our elite team of experienced structural engineers and technical experts possesses extensive project experience and cutting-edge design concepts, with a deep understanding of steel structure mechanics and industry standards.

Utilizing professional design software such as AutoCAD and Tekla Structures, we construct a comprehensive visual design system, from 3D models to 2D engineering plans, accurately representing component dimensions, joint configurations, and spatial layouts. Our services cover the entire project lifecycle, from preliminary schematic design to detailed construction drawings, from complex joint optimization to overall structural verification. We meticulously control details with millimeter-level precision, ensuring both technical rigor and constructability.

We are always customer-focused. Through comprehensive scheme comparison and mechanical performance simulation, we customize cost-effective design solutions for diverse application scenarios (industrial plants, commercial complexes, bridges and plank roads, etc.). While ensuring structural safety, we minimize material consumption and streamline the construction process. We provide comprehensive follow-up services, from drawing delivery to on-site technical briefings. Our professionalism ensures the efficient implementation of every steel structure project, making us a trusted, one-stop design partner.

Packaging steel structures depends on component type, size, transport distance, storage environment, and required protection to prevent deformation, rust, and damage.

Bare Packaging (Unpackaged)

For large/heavy components (columns, beams, trusses)

Direct loading/unloading with lifting equipment; secure connections to prevent damage

Bundled Packaging

For small/medium, regular components (angle steel, channels, pipes, plates)

Bundles must be tight enough to prevent shifting but not cause deformation

Wooden Box/Wooden Frame Packaging

For small, fragile, or high-precision parts, long-distance transport, or export

Provides excellent protection against environmental damage

Special Protective Packaging

Corrosion protection: Apply anti-rust treatment for long-term storage or humid transport

Deformation protection: Add supports for slender or thin-walled components to prevent bending

Transportation: Express (Sample Delivery), Air, Rail, Land, Train, Sea shipping (FCL or LCL or Bulk)

From the moment your product is delivered, our professional team will provide comprehensive support throughout the installation process, offering meticulous assistance. Whether optimizing on-site installation plans, providing technical guidance on key milestones, or collaborating with the construction team, we strive to ensure an efficient and precise installation process, ensuring the stability and safety of your steel structure.

During the after-sales service phase of the manufacturing process, we provide maintenance recommendations tailored to the product's characteristics and answer questions regarding material care and structural durability.

If you encounter any product-related issues during use, our after-sales team will respond promptly, providing professional technical expertise and a responsible attitude to resolve any issues.

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We 13 years gold supplier and accept trade assurance.