-

Aluminum Industrial Profile T bar 6061 6063 6082 T6 Price Per kg Industrial Aluminum Profile Aluminum Extrusion

T-shaped aluminum, also known as industrial aluminum profile, is a commonly used aluminum profile in industrial production. With its unique T-shaped cross-section design, excellent mechanical properties and processing performance, it is widely used in the frame structure production of various mechanical equipment, automation equipment, production lines, workbenches, protective covers and other fields.

-

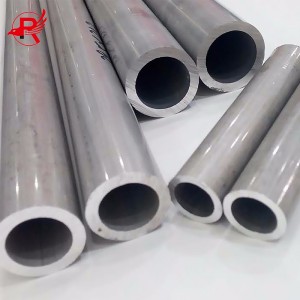

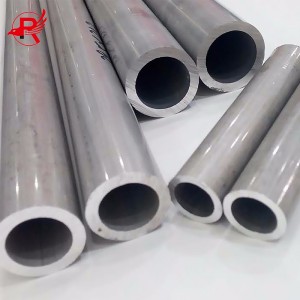

Low Price Different Sizes 6061 Aluminum Tube in Stock

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

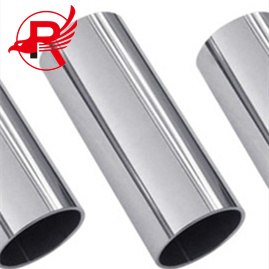

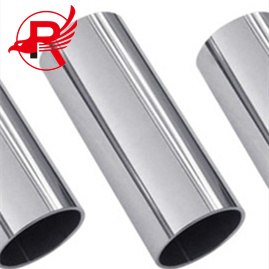

Hot Selling 6000 Series 8 / 10 Inch Seamless Aluminum Round Pipes

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

High Quality Customized A7075 Alloy Aluminum Round Tube

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

Prime Quality 6062 Aluminum Alloy Round Pipe Price

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

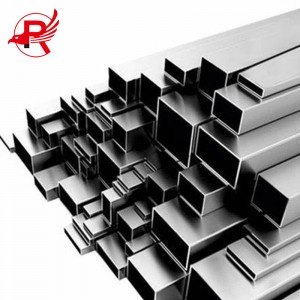

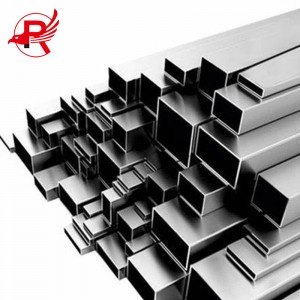

Custom Size 6000 Series Alloy Aluminium Rectangular Pipe Tube

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

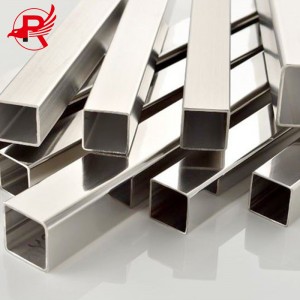

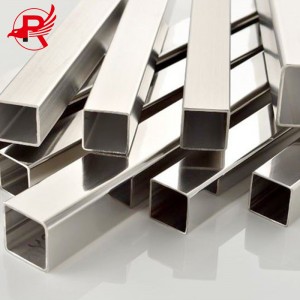

Cheap Prices Custom Size Series Alloy 3003 Aluminium Square Pipe Tube

Aluminum tube is a kind of non-ferrous metal tube, which refers to a metal tubular material that is made of pure aluminum or aluminum alloy and is hollowed along its entire longitudinal length. Common materials are: 1060, 3003, 6061, 6063, 7075, etc. The caliber varies from 10mm to several hundred millimeters, and the standard length is 6 meters. Aluminum tubes are widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household appliances, etc. Aluminum tubes are everywhere in our lives.

-

Top Quality 304 Stainless Steel Tube Best Price 316L Stainless Steel Pipe/Tube

For annealed stainless steel pipes with an inner diameter of more than 6.0 mm and a wall thickness of less than 13 mm, the W-B75 Webster hardness tester can be used. The test is very fast and simple, and is suitable for rapid and non-destructive qualification inspection of stainless steel pipes. For stainless steel pipes with an inner diameter greater than 30mm and a wall thickness greater than 1.2mm, use a Rockwell hardness tester to test HRB and HRC hardness.

-

Alloy 304 3I6 Stainless Steel Rectangular Tubing

Stainless steel square tube

Rectangular tube is a name for square coffin and rectangular coffin, that is, steel tubes with equal and unequal side lengths. It is made of strip steel after process treatment. Generally, the strip steel is unpacked, flattened, crimped, and welded to form a round tube, and then the round tube is rolled into a square tube and then cut to the required length.

Stainless steel rectangular tube is a kind of hollow long strip of steel with a rectangular section, so it is called a rectangular tube.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

Best Price Hairline Rectangular Tube SS 304 304L Stainless Steel Pipe

Stainless steel square tube

Rectangular tube is a name for square coffin and rectangular coffin, that is, steel tubes with equal and unequal side lengths. It is made of strip steel after process treatment. Generally, the strip steel is unpacked, flattened, crimped, and welded to form a round tube, and then the round tube is rolled into a square tube and then cut to the required length.

Stainless steel rectangular tube is a kind of hollow long strip of steel with a rectangular section, so it is called a rectangular tube.

With more than 10 years steel exporting experience to more than 100 countries, we have gained great reputation and lots regular clients.

We will support you well along the whole process with our professional knowledge and prime quality goods.

Stock Sample is Free & Avaliable! Welcome your inquiry!

-

Factory Price 301 302 303 Square Stainless Steel Tube

Stainless steel square tube

Rectangular tube is a name for square coffin and rectangular coffin, that is, steel tubes with equal and unequal side lengths. It is made of strip steel after process treatment. Generally, the strip steel is unpacked, flattened, crimped, and welded to form a round tube, and then the round tube is rolled into a square tube and then cut to the required length.

Stainless steel rectangular tube is a kind of hollow long strip of steel with a rectangular section, so it is called a rectangular tube.

-

Best Price ASTM A312 304 304L 316LStainless Steel Pipe

Stainless steel is an iron alloy that is resistant to rust and corrosion. It contains at least 11% chromium. Stainless steel’s corrosion resistance comes from chromium, which forms a passive film that protects the material and repairs itself in the presence of oxygen.

Its cleanability, strength and corrosion resistance have led to the use of stainless steel in pharmaceutical and food processing plants.

Different types of stainless steel are marked with AISI three-digit numbers, and the ISO 15510 standard lists the chemical composition of stainless steels specified in existing ISO, ASTM, EN, JIS and GB standards in a useful interchange table.

Stock Sample is Free & Avaliable! Welcome your inquiry!

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur