Download the Latest GI Steel Roofing Sheet Specifications and Dimensions.

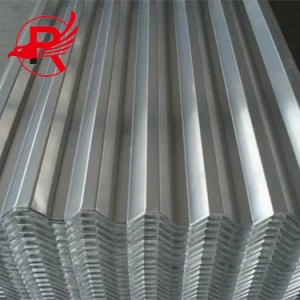

JIS G3302/G3303 Galvanized Steel Roofing Sheet – Durable Corrugated Roof Panels

| Specification | Item | Specification |

| Material Standard | JIS G3302 / G3303 | Commercial Hot-Dip Galvanized Steel |

| Base Material | Low Carbon Steel | SPHC / SS330 / Equivalent |

| Thickness | 0.25–1.20 mm | Customizable according to requirement |

| Width | 600–1250 mm | Effective width can be customized |

| Length | 1–12 m, or Customized | Standard or cut-to-length available |

| Zinc Coating | Z12–Z24 g/m² per side | ~17–33 μm, depending on grade and corrosion requirement |

| Coating Type | Hot-Dip Galvanized (GI) | Regular Spangle / Zero Spangle |

| Profile Type | Corrugated / Trapezoidal / Ribbed | Standard industrial roofing profiles |

| Steel Grade | Commercial Quality | JIS G3302/G3303 Standard |

| Yield Strength | ≥ 230–550 MPa | Grade dependent |

| Surface Finish | Regular Spangle / Zero Spangle | Smooth, uniform zinc coating |

| Dimensional Tolerance | Conforms to JIS G3302 / G3303 | Ensures proper fit and installation |

| Applications | Industrial roofs, warehouses, workshops, residential roofing | Durable and corrosion-resistant |

| Processing Service | Cutting, profiling, punching | Custom profiles available |

| Quality Certification | ISO 9001, SGS / BV Third-Party Inspection | Reliable quality assurance |

| Packing | Standard Seaworthy Export Packing | Secure for long-distance shipment |

Notes and Recommendations:

Zinc Coating is expressed as Z12–Z24 g/m², corresponding to a thickness of approximately 17–33 μm. Z18–Z24 is commonly used for outdoor roofing.

Profile Type: Corrugated, Trapezoidal, Ribbed, etc., can be provided according to customer requirements.

Thickness and Width can be customized on a project-by-project basis, allowing purchasing managers to quickly understand the available options.

Technical Data

JIS G3302/G3303 Galvanized Steel Roofing Sheet Chemical Composition

| Element | JIS G3302 / G3303 SPHC (Typical %) | Notes |

| Carbon (C) | ≤ 0.12–0.15 | Low carbon steel for good formability |

| Manganese (Mn) | 0.30–0.50 | Improves strength |

| Phosphorus (P) | ≤ 0.035 | Impurity control |

| Sulfur (S) | ≤ 0.035 | Impurity control |

| Silicon (Si) | ≤ 0.03–0.10 | Optional, depending on grade |

| Copper (Cu) | ≤ 0.30 | Optional, may improve corrosion resistance |

| Nitrogen (N) | ≤ 0.008 | Optional |

| Others | Balanced | Residual elements within limits |

Notes:

The above composition is typical for commercial hot-dip galvanized steel sheets under JIS G3302 / G3303.

Carbon content ≤ 0.15% ensures good cold formability for roofing profiles.

Other elements (Mn, Si, Cu) vary slightly depending on the mill and intended corrosion resistance.

JIS G3302/G3303 Galvanized Steel Roofing Sheet Mechanical Property

Standard Reference

JIS G3302: Hot-dip zinc-coated steel sheet (commercial quality)

JIS G3303: Hot-dip zinc-coated steel sheet (cold-rolled commercial quality)

Mainly used for roofing, cladding, and light structural applications.

| Property | Typical Value | Notes |

| Tensile Strength (MPa) | 270 – 410 MPa | Depends on base steel grade (SPHC or equivalent) |

| Yield Strength (MPa) | 140 – 270 MPa | Varies by thickness and temper |

| Elongation (%) | 18 – 35% | Measured over a gauge length of 50 mm |

| Bendability | 180° around a radius of 1–3× thickness | Sheet should not crack |

| Hardness (HV) | 80 – 120 | Indicative of base steel and zinc coating |

| Zinc Coating Mass (g/m²) | 60 – 275 g/m² | Usually classed as Z60, Z90, Z120, Z180, Z275 |

| Impact Resistance | Good | Depends on sheet thickness; no brittle fracture under normal handling |

Note: Exact values may vary depending on manufacturer, coating thickness, and steel substrate (commercial quality vs. cold-rolled).

JIS G3302/G3303 Galvanized Steel Roofing Sheet Sizes

| Parameter | Typical Range | Notes |

| Thickness (t) | 0.35 – 1.2 mm | Most roofing sheets are 0.4–0.7 mm; thicker sheets used for industrial roofs. |

| Coating (Z) | Z60 – Z275 g/m² per side | Determines corrosion resistance; Z120–Z180 common for roofing. |

| Width (B) | 600 – 1250 mm (mill finish) | Roll-formed widths vary with profile; effective cover width is slightly less. |

| Length (L) | 2 – 12 m | Can be cut to customer requirements; long sheets reduce joints. |

| Spangle (Zinc coating appearance) | Regular / Minimized / Zero | Depends on aesthetic requirements. |

| Weight | 3–10 kg/m² | Depends on thickness and coating. |

Click the Button on The Right

Main Applications

Industrial Buildings – Factories and manufacturing plants, workshops

Warehouses and Logistical Centers – Storage, distribution

Commercial Buildings – Shopping malls, office buildings, car parks

Residential Roofing: House roofs, villas, low-rise residential building roofs

Agricultural buildings such as farmhouses, shelter for animals

Temporary Structures – Office-space, prefab homes, construction field sheds

Secondary Applications

Wall cladding & Side paneling

Canopies and Car Ports

Shelters and Patio Covers

Suitable Environments

Typical urban areas

Industrial Areas

Regions of high humidity (for zinc-coated products with the thickness class Z180–Z275)

1) Branch Office - Spanish-speaking support, customs clearance assistance, etc.

2) Over 5,000 tons of stock in stock, with a wide variety of sizes

3) Inspected by authoritative organizations such as CCIC, SGS, BV, and TUV, with standard seaworthy packaging

Packing

Outer Packing:

Tighten steel banding to bundler

Wooden pallets or steel frames (optional)

Prevent edge damage with corner protector

Export Packing:

Normal seaworthy export packing

Container and bulk shipment are available

Packing can be tailored to customers' needs.

Delivery

Delivery Time:

Standard sizes: 7-15 days after confirmation of order

Customized profiles or sizes 15-25 days.

Shipping Methods:

20GP / 40GP / 40HQ containers

Break bulk shipment for over sized roofing sheets

Loading Method:

Horizontal stacking with protection

Fasten securely to prevent shifting during transport

Stable cooperation with shipping companies such as MSK, MSC, COSCO efficiently logistics service chain, logistics service chain are we to your satisfaction.

We follow the standards of quality management system ISO9001 in all procedure, and have strict control from packaging material purchase to transport vehicle scheduling. This guarantees the H-beams from the factory all the way to the project site, helping you build on a solid foundation for a trouble free project!

1. What are the differences between JIS G3302 and G3303?

JIS G3302 applies to hot dip galvanized steel sheets on the basis of hot rolled steel used for roofing and general structural purposes.

JIS G3303 is a standard for galvanized steel sheet which is manufactured from cold rolled steel sheet as a base material. It is excellent in surface quality, thickness tolerance and formability, and is suitable for precision roofing profile.

2. What thickness is used for corrugated roofing?

The main thickness of jls g3302/g3303 steel roof sheet is 0.35mm-1.2mm.

0.35–0.50 mm: Seemingly appropriate for roofing of houses and small sheds.

0.50–0.80 mm: For commercial and industrial use buildings.

0.80–1.2 mm: For heavy duty roofs and wide span buildings.

3. What kind of zinc coating weights have?

Regular zinc coating grades are:

Z60, Z90, Z120, Z180 and Z275 (g/m²).

A thick zinc coating results in a much better rust protection, particularly for basement areas or humid tropical weather.

4. Can JIS G3302/G3303 be roll formed into shapes?

Yes, it is. These galvanized steel sheets have good rolling performance and can roll-form into:

Corrugated (wave) profiles

Ribbed or trapezoid profiles

Custom roof can be made .

When made right, they also enjoy good bendability with no cracks.

5. What are mechanical properties, usually?

Standard mechanical properties:

Tensile Strength: 270–410 MPa

Yield Strength: 140–270 MPa

Elongation: 18–35%

The actual value is dependent upon the thickness of the sheet, the base steel, and the coating.

6. What is the size of the sheet?

Thickness: 0.35 – 1.2 mm

Overall Width: 750 – 1250 mm

Width: 700 – 1200 mm (after profiling)

Length: 500 – 6000 mm (custom lengths up to 12,000 mm available)

7. Are these roofing sheets suitable for external use?

Yes. The hot-dip zinc coating offers excellent corrosion resistance, so JIS G3302/G3303 is also applicable for outdoor roof and wall sheet. For severe condition, more zinc coating or color coating should be taken.

8. Can the sheets be painted or color coated?

Certainly. JIS G3302/G3303 galvanized sheets have excellent paint adhesion and are often used as a substrate for pre-painted (PPGI) roofing sheets.

9. Then, how the roofing sheet packed and shipped?

Sheets are tightly packed with steel or plastic strapping, with waterproof protection and edge guards. Special packaging can be made if you want to customize the packaging of the product, to protect your goods in shipping.

10. What are the common uses of JIS G3302/G3303 galvanized roofing sheet?

They are largely applied to:

Residential and commercial roofing

Metal Building Warehouses

Farm buildings and storage

Wall Claddings and Roofing Systems

Contact Details

Address

Kangsheng development industry zone,

Wuqing district, Tianjin city, China.

Phone

Hours

Monday-Sunday: 24-hour Service