ASTM A36 Steel Accessories & Scaffolding Pipes Description

| Parameter |

Specification / Description |

| Product Name |

ASTM A36 Scaffolding Pipe / Carbon Steel Support Tube |

| Material Grade |

Structural carbon steel per ASTM A36 |

| Standards |

ASTM A36 compliant |

| Outer Diameter |

48–60 mm (standard range) |

| Wall Thickness |

2.5–4.0 mm |

| Pipe Length Options |

6 m, 12 ft, or custom lengths for project requirements |

| Pipe Type |

Seamless or welded construction |

| Surface Finish Options |

Black (untreated), Hot-Dip Galvanized (HDG), epoxy/paint coating optional |

| Yield Strength |

≥ 250 MPa |

| Tensile Strength |

400–550 MPa |

| Key Advantages |

High load capacity, improved corrosion resistance (Galvanized), uniform dimensions, safe & easy installation and removal |

| Typical Uses |

Scaffolding systems, industrial platforms, temporary structural supports, staging |

| Quality Certification |

ISO 9001 and ASTM standard compliance |

| Payment Terms |

T/T 30% deposit + 70% balance prior to shipment |

| Delivery Lead Time |

Approx. 7–15 days depending on quantity |

ASTM A36 Steel Accessories & Scaffolding Pipes Size

| Outer Diameter (mm / in) |

Wall Thickness (mm / in) |

Length (m / ft) |

Weight per Meter (kg/m) |

Approx. Load Capacity (kg) |

Notes |

| 48 mm / 1.89 in |

2.5 mm / 0.098 in |

6 m / 20 ft |

4.5 kg/m |

500–600 |

Black steel, HDG optional |

| 48 mm / 1.89 in |

3.0 mm / 0.118 in |

12 m / 40 ft |

5.4 kg/m |

600–700 |

Seamless or welded |

| 50 mm / 1.97 in |

2.5 mm / 0.098 in |

6 m / 20 ft |

4.7 kg/m |

550–650 |

HDG coating optional |

| 50 mm / 1.97 in |

3.5 mm / 0.138 in |

12 m / 40 ft |

6.5 kg/m |

700–800 |

Seamless recommended |

| 60 mm / 2.36 in |

3.0 mm / 0.118 in |

6 m / 20 ft |

6.0 kg/m |

700–800 |

HDG coating available |

| 60 mm / 2.36 in |

4.0 mm / 0.157 in |

12 m / 40 ft |

8.0 kg/m |

900–1000 |

Heavy-duty scaffolding |

ASTM A36 Steel Accessories & Scaffolding Pipes Size

Steel Ringlock Scaffolding Advantages Customized Content

| Customization Category |

Options Available |

Description / Range |

| Dimensions |

Outer Diameter, Wall Thickness, Length |

Diameter: 48–60 mm; Wall Thickness: 2.5–4.5 mm; Length: 6–12 m (adjustable per project) |

| Processing |

Cutting, Threading, Prefabricated Fittings, Bending |

Pipes can be cut to length, threaded, bent, or fitted with couplers and accessories according to project requirements |

| Surface Treatment |

Black Steel, Hot-Dip Galvanized, Epoxy Coating, Painted |

Surface treatment selected based on indoor/outdoor exposure and corrosion protection needs |

| Marking & Packaging |

Custom Labels, Project Info, Shipping Method |

Labels indicate pipe size, ASTM standard, batch number, test report info; packaging suitable for flatbed, container, or local delivery |

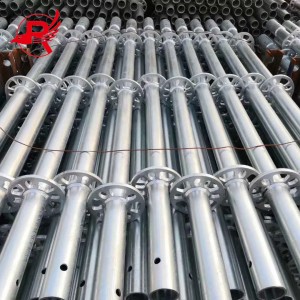

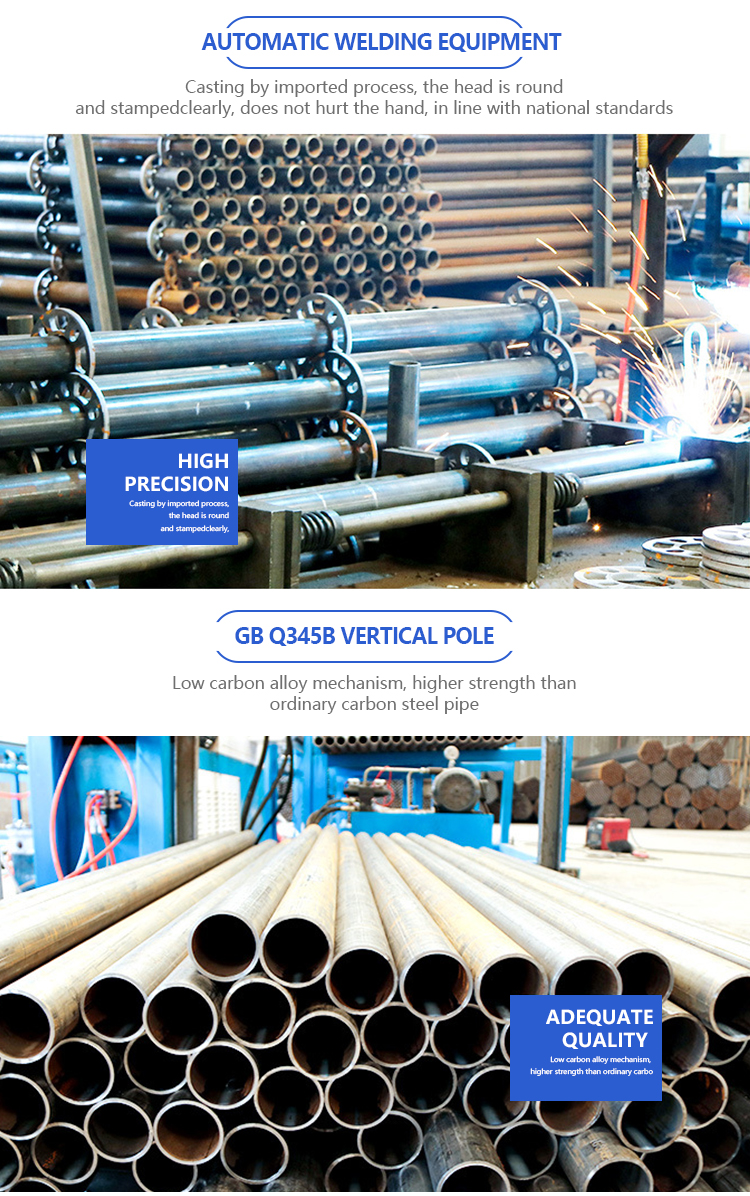

1. Advanced technology

The disc type connection method is 0 mainstream scaffolding connection mode. The reasonable node design can reach the transmission force of each rod through the node center, mainly used in Europe and America 0 and regions. It is an upgraded product of scaffolding, mature technology and connection. Robust, stable structure, safe and reliable.

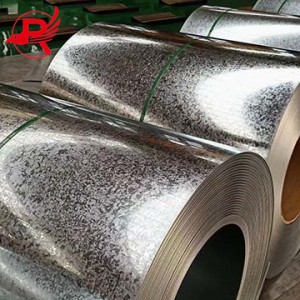

2. Raw material upgrade

The main materials are all low-alloy structural steel (national standard Q345B), the strength is 1.5--2 times higher than that of traditional scaffolding carbon steel pipe (national standard Q235).

3. Hot-dip galvanizing process

The main components are made of internal and external hot-dip galvanizing anti-corrosion technology, which not only improves the service life of the product, but also provides further guarantee for safety, while at the same time making beautiful and beautiful.

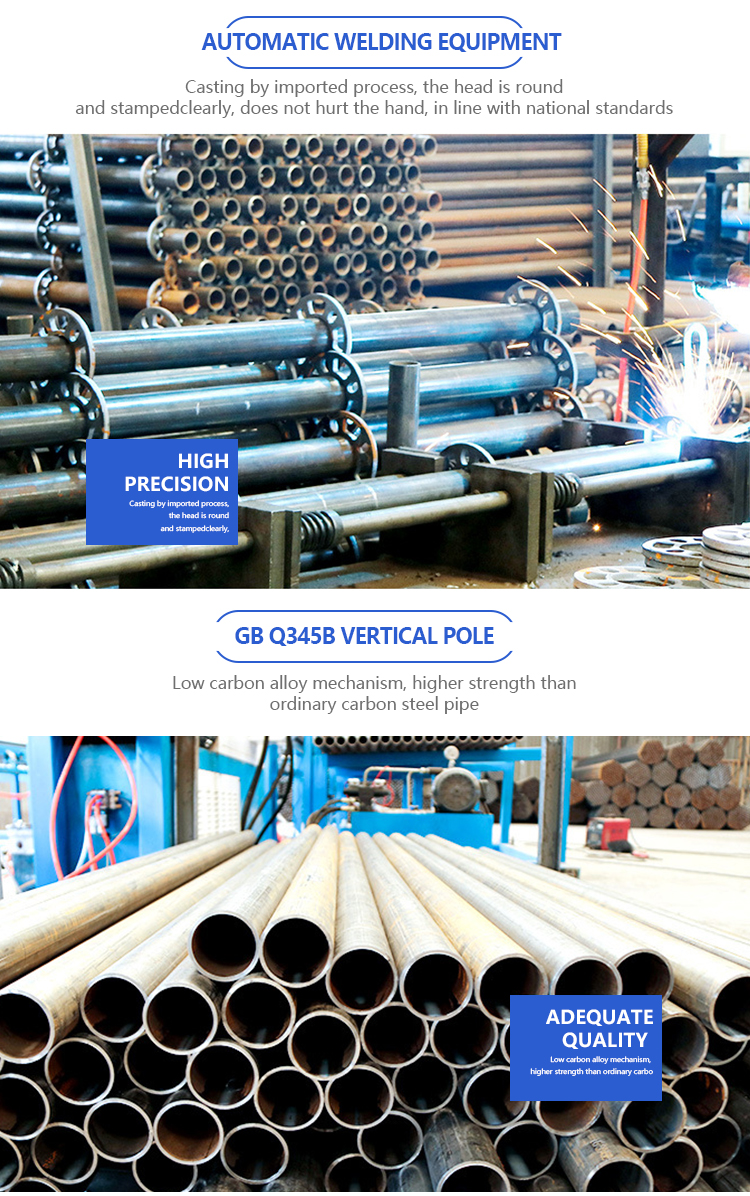

4, reliable quality

The product starts from the cutting, the whole product processing has to go through 20 to the process, and each step is carried out by special plane to reduce the intervention of human factors, especially the production of crossbars and poles, using self-developed fully automatic welding machine. The products have high precision, strong interchangeability and stable and reliable quality.

5, large carrying capacity

Taking the 60 series heavy-duty support frame as an example, the allowable bearing capacity of a single pole with a height of 5 meters is 9.5 tons (safety factor 2). The damage load reached 19 tons. It is 2-3 times that of traditional products.

6, low dosage and light weight

Under normal circumstances, the distance between the poles is 1.5 meters, 1.8 meters, the step of the crossbar is 1.5 meters, the large spacing can reach 3 meters, and the step distance is 2 meters. Therefore, the amount of the same support volume will be reduced by 1/2 compared to the conventional product, and the weight will be reduced by 1/2 to 1/3.

7, fast assembly, easy to use, save money

Due to the small amount and light weight, the operator can assemble it more conveniently. The cost of detachment, transportation, rental and maintenance will be saved accordingly, under normal circumstances.

Steel Ringlock Scaffolding Details

Steel Ringlock Scaffolding Installation Procedure

Our factory