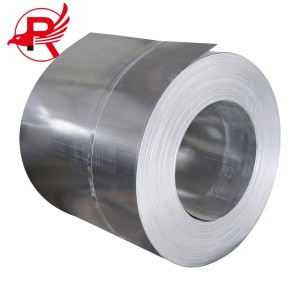

GB/T 2518-2008 DX51D/DX52D/DX53D+Z275 Pre-painted Steel Coil | Domestic Low-Carbon Steel, 275 g/m² Zinc Coating, for Construction & Industrial Use

| Category | Specification | Category | Specification |

| Standard | GB/T 2518-2008 | Applications | Roofing sheets, wall panels, appliance panels, architectural decoration |

| Material / Substrate | DX51D, DX52D, DX53D, DX51D+Z275 | Surface Features | Smooth, uniform coating with excellent corrosion resistance |

| Thickness | 0.12 – 1.2 mm | Packaging | Moisture-proof inner wrap + steel strapping + wooden or steel pallet |

| Width | 600 – 1500 mm (customizable) | Coating Type | Polyester (PE), High-durability Polyester (SMP), PVDF optional |

| Zinc Coating Weight | Z275 (275 g/m²) | Coating Thickness | Front: 15–25 µm; Back: 5–15 µm |

| Surface Treatment | Chemical pre-treatment + coating (smooth, matte, pearl, fingerprint-resistant) | Hardness | HB 80–120 (depends on substrate thickness and processing) |

| Coil Weight | 3–8 tons (customizable per transport/equipment) | — | — |

| Serial Number | Material | Thickness (mm) | Width (mm) | Roll Length (m) | Weight (kg/roll) | Application |

| 1 | DX51D | 0.12 – 0.18 | 600 – 1250 | Customization on demand | 2 – 5 Tons | Roofing, wall panels |

| 2 | DX51D | 0.2 – 0.3 | 600 – 1250 | Customization on demand | 3 – 6 Tons | Home appliances, billboards |

| 3 | DX51D | 0.35 – 0.5 | 600 – 1250 | Customization on demand | 4 – 8 Tons | Industrial equipment, pipes |

| 4 | DX51D | 0.55 – 0.7 | 600 – 1250 | Customization on demand | 5 – 10 Tons | Structural materials, roofing |

| 5 | DX52D | 0.12 – 0.25 | 600 – 1250 | Customization on demand | 2 – 5 Tons | Roofing, walls, appliances |

| 6 | DX52D | 0.3 – 0.5 | 600 – 1250 | Customization on demand | 4 – 8 Tons | Industrial panels, pipes |

| 7 | DX52D | 0.55 – 0.7 | 600 – 1250 | Customization on demand | 5 – 10 Tons | Structural materials, roofing |

| 8 | DX53D | 0.12 – 0.25 | 600 – 1250 | Customization on demand | 2 – 5 Tons | Roofing, walls, decorative panels |

| 9 | DX53D | 0.3 – 0.5 | 600 – 1250 | Customization on demand | 4 – 8 Tons | Appliances, industrial equipment |

| 10 | DX53D | 0.55 – 0.7 | 600 – 1250 | Customization on demand | 5 – 10 Tons | Structural materials, machinery panels |

Notes:

Each grade (DX51D, DX52D, DX53D) can be supplied in thin, medium, and thick gauge coil specifications.

Thickness & strength based recommended application scenarios are relatively suitable for actual market.

The width, coil length and coil weight can also be customized according to the requirement of factory and transportation.

Our PPGI steel coils can be made according to the detailed conditions of your projects. For strips, we offer substrates including DX51D, DX52D, DX53D and other standard grades, zinc coatings from Z275 and above, with good corrosion protection, smooth surface and excellent formability.

Coating materials available:

Thickness: 0.12 – 1.2 mm

Width: 600 – 1500 mm (customizable)

Type of Coating & Color: PE, SMP, PVDF or others according to your requirement

Coil Weight & Length: You can determine these both Coil Weight & Length according to your production and shipping needs

These customized color-coated steel coils provide an excellent balance of performance and attractive appearance. They are also best suited for roof sheets, wall cladding and domestic appliances, industrial and building materials. With our custom solutions, our steel coils deliver efficiency, strength and beauty making them worth the most for your projects.

| Standard | Common Grades | Description / Notes |

| EN (European Standard) EN 10142 / EN 10346 | DX51D, DX52D, DX53D, DX51D+Z275 | Low-carbon hot-dip galvanized steel. Zinc coating 275 g/m², good corrosion resistance. Suitable for roofing, wall panels, and appliances. |

| GB (Chinese Standard) GB/T 2518-2008 | DX51D, DX52D, DX53D, DX51D+Z275 | Domestic common low-carbon steel grades. Zinc coating 275 g/m². Used for construction, industrial buildings, and appliances. |

| ASTM (American Standard) ASTM A653 / A792 | G90 / G60, Galvalume AZ150 | G90 = 275 g/m² zinc coating. Galvalume AZ150 offers high corrosion resistance. Suitable for industrial and commercial buildings. |

| ASTM (Cold Rolled Steel) ASTM A1008 / A1011 | CR Steel | Cold-rolled steel used as base material for PPGI production. |

| Popular Pre-Painted Coil Colors | ||

| Color | RAL Code | Description / Common Use |

| Bright White | RAL 9003 / 9010 | Clean and reflective. Used in appliances, indoor walls, and roofing. |

| Off-White / Beige | RAL 1014 / 1015 | Soft and neutral. Common in commercial and residential buildings. |

| Red / Wine Red | RAL 3005 / 3011 | Elegant and classic. Popular for rooftops and industrial buildings. |

| Sky Blue / Blue | RAL 5005 / 5015 | Modern appearance. Used in commercial buildings and decorative applications. |

| Gray / Silver Gray | RAL 7001 / 9006 | Industrial look, dirt-resistant. Common in warehouses, roofs, and facades. |

| Green | RAL 6020 / 6021 | Natural and eco-friendly. Suitable for garden sheds, roofs, and outdoor constructions. |

Due to its good anti-corrosion performance, good appearance and process performance, PPGI color coated coils product is applied in many fields of industry and life, such as:

Building and Construction

When it comes to roofing, wall cladding and structural uses, color coated coils will not only bring color enhancements to buildings, they can also increase weather resistance and longevity.

Transportation Industry

Color coated coil for transportation products such as container, automobile body, carriage plate has features of light weight and wear resistance, which can effectively enhance transportation efficiency and transportation.

Scale Equipment and Pipes

With superb corrosion resistance, it's ideal for industrial pipes, machinery enclosures, and storage.

Ceilings and Partitions: Used for industrial ceilings, office partitions and other interior applications, it is simple to fit and maintain.

Home Appliance

As used in outer covers of refrigerators, washing machines, air conditioners, and other household appliances, color coated coils give a polished, attractive finish to the panels and make them easy to clean.

Home Deco

Used in furniture panels, kitchen cabinet and decorative board, the colour coated coils can produce in multiple colors and are the best choice for aesthetical and practical results.

Note:

1. Free sampling, 100% after-sales quality assurance, Support any payment method;

2. All other specifications of PPGI are available according to your

requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

First to decoiler -- stitching machine, roller, tension machine, open-book looping soda-wash degreasing -- cleaning, drying passivation -- at the beginning of drying -- touched -- the early drying --finish fine tu --finish drying --Air-cooled and water-cooled -rewinding looper -Rewinding machine -----(rewinding to be packed into storage).

Packaging is generally by steel iron package and water proof package, steel strip binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

1. What is the DX51D Z275 steel?

Hot-dip galvanized mild steel, PPGI/galvanized coil substrate. Z275 = zinc layer 275g/m2, good corrosion resistance in outdoors/industrial applications.

2. What is the purpose of PPGI steel coil?

Pre-Painted Galvanized Iron. Sturdy, handsome, corrosion-resistant. Excellent for roofing, walling, appliances. Ex:) Steel Coil PPGI,9003 PPGI Coil.

3. Which steel grades are usual in PPGI coils?

EU (EN 10346/10142): DX51D, DX52D, DX53D, DX51D+Z275 China (GB/T 2518): Same as EU grades US (ASTM A653/A792): G90, G60, AZ150; CR Steel (ASTM A1008/A1011) as base material

4. What pre-painted coil colors are most popular?

Bright White/Pearl White (RAL9010/9003), Beige/Off-White (RAL1015/1014), Red/Wine Red (RAL3005/3011), Sky Blue/Blue (RAL5005/5015), Gray/Silver Gray (RAL7001/9006), Green (RAL6020/6021)

5. What are the application of DX51D Z275 and PPGI Coil?

Roofing/wall panels, industrial commercial building,ERW galvanised pipes, home appliances/furnitures, galvalume coils with high salt-spray.

6. What is the DX51D equivalent for ASTM?

ASTM A653 Grade C; DX52D alternative for different thickness/zinc coating. Suit for ASTM standard projects.

7. Production scale of Royal Steel Group?

5- production bases (5,000㎡per each). Main products: steel pipe /coil /plate /structure. The additions for 2023: 3 steel coil + 5 steel pipe production lines,

8. Can you make different colors / specifications?

Yes Customized PPGI/galvanized/galvalume coils (thickness, width, coating weight, RAL color) according to client s requirements.