-

Factory Supply Z275 Dx51d Cold Rolled Dipped Gi Galvanized Steel Sheets

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective rust prevention method that is often used, and about half of the world’s zinc production is used in this process.

-

Hot Sales Top Quality Dx52d Z140 Galvanized Steel Sheet for Building Iron Roof Sheet

Galvanized sheet is a kind of metal material that is coated with zinc on the surface of steel plate, mainly used to prevent steel corrosion and increase its durability. Galvanized sheet is usually a hot-dip galvanizing process, that is, the steel plate is immersed in a molten zinc solution to form a uniform zinc layer on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life.

Galvanized sheet is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized sheets are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In the automotive industry, galvanized sheets are used to make body shells and components to increase their weather resistance and durability.

In general, galvanized sheet has good corrosion resistance and mechanical properties, is an important metal material, for protecting steel from corrosion and extending its service life plays an important role.

-

Construction Material High Quality Hot Dipped Galvanized Steel Coils z275

galvanized coils, is a metal material that prevents corrosion of steel by plating a layer of zinc on the surface of the steel coil. Galvanized coils are usually hot-dip galvanizing, in which the steel coil is immersed in a molten zinc solution so that a uniform zinc layer is formed on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life.

Galvanized coil has good corrosion resistance, high strength and hardness, good processing performance and decorative performance. It is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized rolls are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In the automotive industry, galvanized coils are used to make body shells and components to increase their weather resistance and durability.

In general, galvanized coil has good corrosion resistance and mechanical properties, and is an important metal material that plays an important role in protecting steel from corrosion and extending its service life.

-

Factory Cold Folled Hot Dipped DX53D Galvanized Steel Coil for Customers Demands

Galvanized coil is a metal material, by plating a layer of zinc on the surface of the steel coil to prevent steel corrosion process. Usually using hot dip galvanizing process, the steel coil is immersed in a molten zinc solution to form a uniform zinc layer on its surface. This treatment can effectively prevent the steel from being eroded by air, water and chemicals, and extend its service life. Galvanized coil has good corrosion resistance, high strength and hardness, good processing performance and decorative performance. It is widely used in construction, furniture, automobile manufacturing, power equipment and other fields. In the construction industry, galvanized rolls are often used to make components such as roofs, walls, pipes and doors and Windows to improve their corrosion resistance and aesthetics. In general, galvanized coil is an important metal material that plays an important role in protecting steel from corrosion and extending its service life.

-

Low Price High Quality BWG 20 21 22 SAE1008 GI Galvanized Binding Wire

Galvanized steel wire surface smooth, smooth, no cracks, joints, thorns, scars and corrosion, galvanized layer uniform, strong adhesion, corrosion resistance lasting, toughness and elasticity is excellent. The tensile strength should be between 900Mpa-2200Mpa (wire diameter Φ0.2mm- 4.4mm). Galvanized steel wire is made of drawing high quality carbon structural steel, and then galvanized (galvanizing or hot-dip galvanizing).The thickness of the hot-dip zinc layer is 250g/m. Greatly improved the corrosion resistance of steel wire.

-

Manufacturer Wholesale Outer Diameter 3 Inch Round Galvanized Steel Pipe

Galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

-

High Quality Gi Galvanized Steel Iron Pipe Steel Tube for Sale

Galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

-

60.3*2.5mm Welded Galvanized Gi Iron Steel Pipe Price From China Factory

Galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

-

Manufacture Q345 Cold Rolled Galvanized C Channel Steel

Galvanized C-shaped steel is a new type of steel made of high-strength steel plate, then cold-bent and roll-formed. Compared with traditional hot-rolled steel, the same strength can save 30% of the material. When making it, the given C-shaped steel size is used. C-shaped steel The forming machine automatically processes and forms.

Compared with ordinary U-shaped steel, galvanized C-shaped steel can not only be preserved for a long time without changing its material, but also has relatively strong corrosion resistance, but its weight is also slightly heavier than the accompanying C-shaped steel. It also has a uniform zinc layer, smooth surface, strong adhesion, and high dimensional accuracy. All surfaces are covered by a zinc layer, and the zinc content on the surface is usually 120-275g/㎡, which can be said to be a super protective one. -

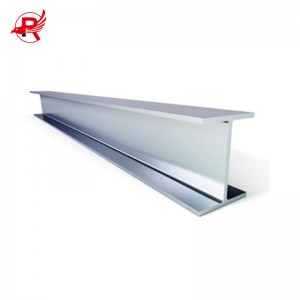

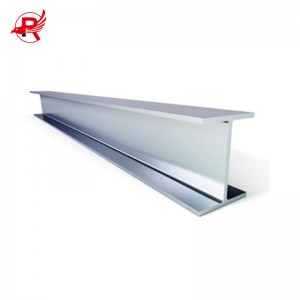

High Quality SS400 H Section Galvanized Steel H Shape Beam

H-shaped steel is a kind of economically efficient profile with more optimized section area distribution and more reasonable strength-to-weight ratio, which is named because its section is the same as the English letter “H”. Because all parts of H-shaped steel are arranged at right angles, H-shaped steel has the advantages of strong bending resistance, simple construction, cost saving and light structural weight in all directions, and has been widely used.

-

High Grade Q345B 200*150mm Carbon Steel Welded Galvanized Steel H Beam for Construction

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

Hot Rolled Color Coated Coil / PPGI Steel Coil RAL 9002 For Building Materials

PPGI is a product of hot galvanized plate, hot aluminum plated zinc plate, electrogalvanized plate, etc., after surface pretreatment (chemical degreasing and chemical conversion treatment), coated with one or several layers of organic coating on the surface, and then baked and cured. Because coated with a variety of different colors of organic paint color steel coil named, referred to as color coated coil.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur