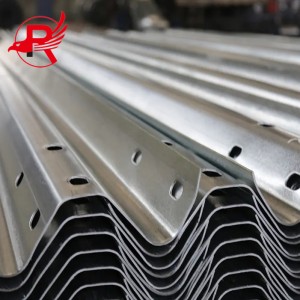

Factory Direct Customized Price Steel Galvanized Thrie Beam Guardrail Road Safety Crash Barrier with CE Certificate

|

Name

|

W Beam Guardrail Per AASHTO M180

|

|

Size

|

Effective Length of Beam Section 12.5 ft or 25.0 ft

Can be Customized |

|

Steel Thickness

|

Class A = 2.67MM (0.105 in.)

Class B = 3.43MM (0.135 in.)

Can be customized.

|

|

Surface Treatment

|

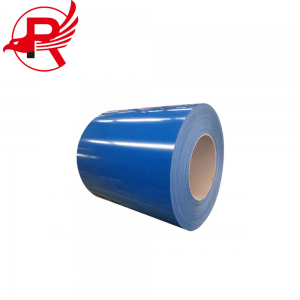

Hot Dip Galvanized as per ASTM A653

|

|

Zinc Coating Thickness

|

Type 1 = Zinc coated 550 g/sq. meter minimum single spot

Type 2 = Zinc coated 1100 g/sq. meter minimum single spot

Type 3 =Uncoated Steel

Type 4 = Weathering Steel

Can be customized.

|

|

Free Sample

|

Available

|

|

Production Time:

|

Approximately 7~15 business days.

|

|

Production Capacity

|

60000 Tons/Month

|

|

Warranty

|

2 Years

|

metal barrier have a wide variety of applications, including:

1. Security: Metal barriers can be used to physically protect property or prevent unauthorized access to restricted areas. They are commonly used in high security facilities such as airports, government buildings and military installations.

2. Vehicle control: metal barrier fencing such as bollards, guardrails, and gates can be used to regulate vehicle traffic and prevent accidents. They are commonly used in car parks, toll booths and construction sites.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

The process of steel road barrier involves several steps. Here is an overview of the general process:

1. Design: The initial phase of metal guardrail production is the designing of the guardrails. Designers create designs using computer aided design (CAD) programs.

2. Material Selection: The next stage is to choose suitable material for the obstacle, now that you've finalized the design. Steel, aluminum and iron are the most frequently used materials.

3. Cutting: Then we cut it to the required size and shape when we have chosen the materials. This is possible by using different cutting instruments such as water jet, laser or plasma cutter.

4. Forming: After cut, the material can be formed to the target shape and size by bending, rolling and stamping, etc.

5. Welding: When the components are formed, they are welded to the finished barrier. Welding is performed by different methods, among them arc welding and gas welding.

6. Finishing: The obstacle is welded, then finished. This can involve sandblasting, powder coating or painting to protect the metal from the elements and give the metal a decorative finish.

7. Quality Control: Metal fences undergo a quality control test before being dispatched to make sure they meet the necessary standards and are not defective.

In conclusion, the production of a metal barrier is a multistage process that is a difficult one which necessitates a team of experts having specialized knowledge and equipment.

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: 30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We 13 years gold supplier and accept trade assurance.