Download the Latest GI Steel Roofing Sheet Specifications and Dimensions.

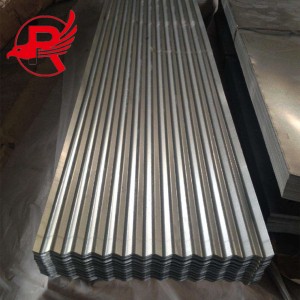

EN 10346 DX51D+Z Galvanized Steel Roofing Sheet | Corrosion-Resistant & Long-Lasting

| Item | Specification | Item | Specification |

| Material Standard | EN 10346 DX51D+Z | Steel Grade | DX51D+Z |

| Base Material | Low Carbon Steel | Yield Strength | ≥ 230–550 MPa (Grade Optional) |

| Thickness | 0.25–1.20 mm | Width | 600–1250 mm (Effective Width Customized) |

| Length | 1–12 m, or Customized | Zinc Coating | Z60–Z275 g/m² |

| Coating Type | Hot-Dip Galvanized (GI) | Surface Finish | Regular Spangle / Zero Spangle |

| Profile Type | Corrugated / Trapezoidal / Ribbed | Dimensional Tolerance | Conforms to EN 10346 / ASTM A653 |

| Applications | Industrial roofs, warehouses, workshops, residential roofing | Processing Service | Cutting, profiling, punching |

| Quality Certification | ISO 9001, SGS / BV Third-Party Inspection | Packing | Standard Seaworthy Export Packing |

Technical Data

EN 10346 DX51D+Z Galvanized Steel Roofing Sheet Chemical Composition

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Aluminium (Al) | Others |

| Content (wt%) | ≤ 0.12 | ≤ 0.60 | ≤ 0.045 | ≤ 0.045 | ≤ 0.03–0.15 | 0.015–0.06 | Balance Fe |

Notes:

DX51D+Z is a low-carbon steel with good formability and suitable for hot-dip galvanizing.

Coating with Zinc (Z) has excellent corrosion resistance.

The composition may vary slightly from producer to producer or rolling according to process, but the above values are the standard range.

EN 10346 DX51D+Z Galvanized Steel Roofing Sheet Mechanical Property

| Property | Typical Value |

| Yield Strength (ReH) | 140–280 MPa (depends on thickness) |

| Tensile Strength (Rm) | 270–410 MPa |

| Elongation (A50) | 23–34% |

| Hardness (HB) | ~120 HB (varies with cold-rolled thickness) |

| Bend Test | 180° bend over sheet thickness without cracking (depends on thickness) |

| Zinc Coating (Z) | Z60 – Z275 g/m² per side (depending on corrosion requirement) |

Notes

Thickness: Normal roofing thicknesses range from 0.4 mm to 1.0 mm.

Coating: Z60–Z275 offers light to heavy corrosion protection; higher values are applied in aggressive environments.

Formability: DX51D+Z can be roll-formed, bent or cut with ease, which make it a perfect material for roof profiles.

Grades For Roofing: We usually use DX51D+Z100 or Z120 for the normal roofing in good balance between cost and corrosion protection.

EN 10346 DX51D+Z Galvanized Steel Roofing Sheet Sizes

| Parameter | Typical Range | Notes |

| Thickness (t) | 0.35 – 1.2 mm | Most roofing sheets are 0.4–0.7 mm; thicker sheets used for industrial roofs. |

| Coating (Z) | Z60 – Z275 g/m² per side | Determines corrosion resistance; Z120–Z180 common for roofing. |

| Width (B) | 600 – 1250 mm (mill finish) | Roll-formed widths vary with profile; effective cover width is slightly less. |

| Length (L) | 2 – 12 m | Can be cut to customer requirements; long sheets reduce joints. |

| Spangle (Zinc coating appearance) | Regular / Minimized / Zero | Depends on aesthetic requirements. |

| Weight | 3–10 kg/m² | Depends on thickness and coating. |

Click the Button on The Right

Main Applications

Industrial Buildings – Factories and manufacturing plants, workshops

Warehouses and Logistical Centers – Storage, distribution

Commercial Buildings – Shopping malls, office buildings, car parks

Residential Roofing: House roofs, villas, low-rise residential building roofs

Agricultural buildings such as farmhouses, shelter for animals

Temporary Structures – Office-space, prefab homes, construction field sheds

Secondary Applications

Wall cladding & Side paneling

Canopies and Car Ports

Shelters and Patio Covers

Suitable Environments

Typical urban areas

Industrial Areas

Regions of high humidity (for zinc-coated products with the thickness class Z180–Z275)

1) Branch Office - Spanish-speaking support, customs clearance assistance, etc.

2) Over 5,000 tons of stock in stock, with a wide variety of sizes

3) Inspected by authoritative organizations such as CCIC, SGS, BV, and TUV, with standard seaworthy packaging

Packing

Outer Packing:

Tighten steel banding to bundler

Wooden pallets or steel frames (optional)

Prevent edge damage with corner protector

Export Packing:

Normal seaworthy export packing

Container and bulk shipment are available

Packing can be tailored to customers' needs.

Delivery

Delivery Time:

Standard sizes: 7-15 days after confirmation of order

Customized profiles or sizes 15-25 days.

Shipping Methods:

20GP / 40GP / 40HQ containers

Break bulk shipment for over sized roofing sheets

Loading Method:

Horizontal stacking with protection

Fasten securely to prevent shifting during transport

Stable cooperation with shipping companies such as MSK, MSC, COSCO efficiently logistics service chain, logistics service chain are we to your satisfaction.

We follow the standards of quality management system ISO9001 in all procedure, and have strict control from packaging material purchase to transport vehicle scheduling. This guarantees the H-beams from the factory all the way to the project site, helping you build on a solid foundation for a trouble free project!

1.What is EN 10346 DX51D+Z steel?

EN 10346 DX51D+Z is a cold rolling low carbon steel sheet with zinc coating (galvanized) used for rust prevention.

DX51D: Cold rolled steel good for forming and bending.

+Z: Hot-dip zinc coated for resilience.

Application: roofing, cladding, gutter, light industrial buildings.

2.The Advantage

Corrosion Resistant: The zinc coating prevent steel from rusting.

Light & Buildable - Can be roll-formed, bent and cut.

Long Life: Minimal Maintenance Over A Long Life.

Affordable: A budget-friendly options for the residential, commercial and industrial roofs.

3.Service Life

Normal surroundings: 15–25 years.

Z180–Z275 or pre-painted sheets are recommmended in coastal or industrial areas.

4.Painting / Coating Options

It can be pre painted (PPGI) with polyester, PVDF or other paints to enhance the appearance and provide additional protection against corrosion.

5.Industrial Applications

Ideal for medium-duty general purpose roofing.

Severe heavy-duty loads may necessitate the use of thicker sheets, or structural steel (i.e. ASTM A653 G60).

6.Maintenance Tips

Clean roof from debris, leaves and dust.

Do not scratches your skin off steel.

Contact Details

Address

Kangsheng development industry zone,

Wuqing district, Tianjin city, China.

Phone

Hours

Monday-Sunday: 24-hour Service