API 5L Gr. B/X42 /X52 /X60 /X65 Psl2 Carbon Steel Line Pipe

| Grades | API 5L Grade B, X42, X52, X56, X60, X65, X70, X80 |

| Specification Level | PSL1, PSL2 |

| Outer Diameter Range | 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches. |

| Thickness Schedule | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Manufacturing Types | Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW |

| Ends Type | Beveled ends, Plain ends |

| Length Range | SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized |

| Protection Caps | plastic or iron |

| Surface Treatment | Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined |

API 5L pipe refers to carbon steel pipe used in oil and gas transmission systems. It is also used to transport other fluids such as steam, water, and mud.

The API 5L specification covers both welded and seamless fabrication types.

Welded Types: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Typical varieties of API 5L welded pipe are as below:

ERW: Electric resistance welding is used for pipe with diameter less than 24 inch.

DSAW/ SAW: Double-sided submerged arc welding/submerged arc welding is another method of welding that can be used in place of ERW for large diameter pipe.

LSAW: Longitudinal Submerged Arc Welding used for up to 48 inches in diameter pipe. Known as the JCOE forming process.

SSAW/HSAW: Spiral submerged arc welding/spiral submerged arc welding up to 100 inches diameter pipe.

Seamless Pipe Types: Hot-rolled Seamless Pipe and Cold-rolled Seamless Pipe

Seamless pipe is typically used for small diameter pipes (typically less than 24 inches).

(Seamless steel pipe is more commonly used than welded pipe for pipe diameters less than 150 mm (6 inches).

We also offer large diameter seamless pipe. Using a hot-rolled manufacturing process, we can produce seamless pipe up to 20 inches (508 mm) in diameter. If you require seamless pipe larger than 20 inches in diameter, we can produce it using a hot-expanded process up to 40 inches (1016 mm) in diameter.

API 5L specifies the following grades: Grade B, X42, X46, X52, X56, X60, X65, X70, and X80.

There are many different grades of steel for API 5L steel pipe such as Grade B, X42, X46, X52, X56, X60, X65, X70, and X80. With the increase of steel grade, the carbon equivalent control is more stringent, the mechanical strength is higher.

Also, the chemical composition of the API 5L seamless and welded pipes for a particular grade is not the same, the welded pipe has more higher demands and less amount of carbon and sulfur.

Chemical Composition for PSL 1 pipe with t ≤ 0.984” |

|||||||

| Steel Grade | Mass fraction, % based on heat and product analyses a,g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| max b | max b | max | max | max | max | max | |

| Seamless Pipe | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Welded Pipe | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; and Mo ≤ 0.15%, | |||||||

| b. For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70., | |||||||

| c. Unless otherwise agreed NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Unless otherwise agreed., | |||||||

| f. Unless otherwise agreed, NB + V = Ti ≤ 0.15%, | |||||||

| g. No deliberate addition of B is permitted and the residual B ≤ 0.001% | |||||||

| Chemical Composition for PSL 2 pipe with t ≤ 0.984” | |||||||||||||||||||||

| Steel Grade | Mass fraction, % based on heat and product analyses | Carbon Equiv a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Other | CE IIW | CE Pcm | |||||||||||

| max b | max | max b | max | max | max | max | max | max | max | ||||||||||||

| Seamless and Welded Pipe | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | As agreed | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | i,j | As agreed | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | As agreed | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | As agreed | |||||||||||

| Welded Pipe | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | i,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | i,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, CE limits shall be as agreed. The CEIIW limits applied fi C > 0.12% and the CEPcm limits apply if C ≤ 0.12%, | |||||||||||||||||||||

| b. For each reduction of 0.01% below the specified maximum for C, an increase of 0.05% above the specified maximum for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; up to a maximum of 2.00% for grades ≥ L485 or X70, but ≤ L555 or X80; and up to a maximum of 2.20% for grades > L555 or X80., | |||||||||||||||||||||

| c. Unless otherwise agreed Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% and Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Unless otherwise agreed, | |||||||||||||||||||||

| g. Unless otherwise agreed, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% and MO ≤ 0.50%, | |||||||||||||||||||||

| i. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% and MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% and MO ≤ 0.80%, | |||||||||||||||||||||

| l. For all PSL 2 pipe grades except those grades with footnotes j noted, the following applies. Unless otherwise agreed no intentional addition of B is permitted and residual B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Delivery Condition | Pipe grade |

| PSL1 | As-rolled, normalized, normalizing formed | A |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered or if agreed Q&T SMLS only | B | |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | As-rolled | BR, X42R |

| Normalizing rolled, normalizing formed, normalized or normalized and tempered | BN, X42N, X46N, X52N, X56N, X60N | |

| Quenched and tempered | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Thermomechanical rolled or thermomechanical formed | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Thermomechanical rolled | X90M, X100M, X120M | |

| The suffice (R, N, Q or M) for PSL2 grades, belongs to the steel grade |

PSL1 and PSL2 are different in the scope of testing as well as in their chemical and mechanical properties.

PSL2 is more stringent than the PSL1 in chemical composition, tensile properties, impact test, non-destructive testing and so on.

Impact Testing

Only PSL2 requires impact testing: except X80.

NDT: Non Destructive Testing. PSL1 does not require non destructive testing in case of discounting non destructive testing is applicable. PSL2 does.

(Non-destructive testing: Non-destructive testing and testing in the API 5L standard uses radiographic, ultrasonic, or other methods (without destroying the material) to detect defects and imperfections in pipelines.)

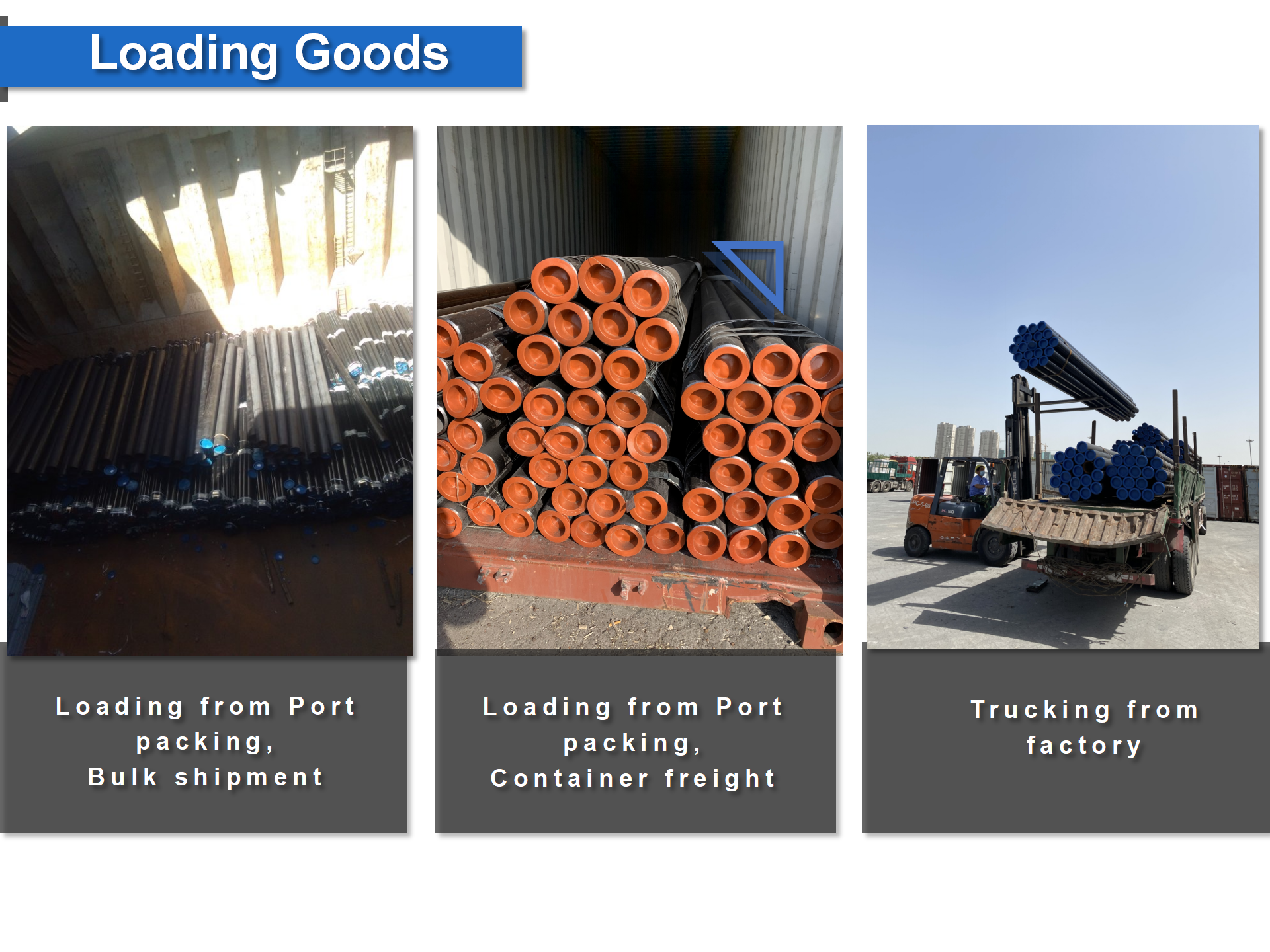

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Precautions for packaging and transportation of carbon steel pipes

1.API 5L Steel Pipe must be protected from damage caused by collision, extrusion and cuts during transportation, storage and use.

2. While handling carbon steel pipes You’re should pay attention to the explosion, fire, poisoning and other accident, and be in line with the safety operation procedures.

3. During use, carbon steel API 5L Pipe should avoid contact with high temperatures, corrosive media, etc. If used in these environments, carbon steel pipes made of special materials such as high temperature resistance and corrosion resistance should be selected.

4. The selection of carbon steel pipe should be that of suitable material and specification according to comprehensive factors including the use environment, the medium nature, pressure, temperature and so on.

5. Necessary inspections and tests shall be conducted before carbon steel pipe is used to prove its quality is up to the standard.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We 13 years gold supplier and accept trade assurance.