Top Suppliers 304 Stainless Steel Round Bar - Factory Price 304 316 321 Stainless Steel Wire Rods – Royal Group

Top Suppliers 304 Stainless Steel Round Bar - Factory Price 304 316 321 Stainless Steel Wire Rods – Royal Group Detail:

Product Detail

| Product Name | Stainless steel wire |

| Type

|

200 series: 201,202 |

| 300 series: 301,302,304,304L,308,309S,310s,316,316L,321,347 | |

| 400 series: 410,420,430,434 | |

| Wire diameter | 0.02-5mm |

| Standard | ASTM AISI GB JIS SUS DIN |

| Length | As customers’ requirement |

| Packing | Spool or roll |

| MOQ | 50kg |

| Delivery | 20 days after received the deposit |

| Usage | Lifting,fixing,cableway,hanging,supporting,refloatation,haulage. |

Main Application

Stainless steel wire is widely use for lifting, fixing, cableway, hanging, supporting, refloatation, haulage,making kitchen utensils, steel balls, etc.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

Stainless Steel Wire Specification

|

Specification |

Grade |

Symbol |

|

|

AISI/SAE |

DIN |

||

|

Auestenite |

302HQ |

1.4567 |

WSA |

|

304 |

1.4301 |

WSB |

|

|

304HC/304J3 |

- |

||

|

305 |

1.4303 |

||

|

316 |

1.4401 |

||

|

Martensite |

430 |

1.4016 |

WSB |

|

434 |

1.4113 |

||

|

Ferrite |

410 |

1.4006 |

|

- Wire diameter possible range: 5mm ~ 40mm

- Packaging form: 100kg ~ 1,000kg / Single weight can be changed according to customer’s order.

Wire Diameter Range

| Wire diameter (mm) | Allowable tolerance (mm) | Maximum deviation of diameter (mm) |

| 0.020-0.049 | +0.002 -0.001 | 0.001 |

| 0.050-0.074 | ±0.002 | 0.002 |

| 0.075-0.089 | ±0.002 | 0.002 |

| 0.090-0.109 | +0.003 -0.002 | 0.002 |

| 0.110-0.169 | ±0.003 | 0.003 |

| 0.170-0.184 | ±0.004 | 0.004 |

| 0.185-0.199 | ±0.004 | 0.004 |

| 0.-0.299 | ±0.005 | 0.005 |

| 0.300-0.310 | ±0.006 | 0.006 |

| 0.320-0.499 | ±0.006 | 0.006 |

| 0.500-0.599 | ±0.006 | 0.006 |

| 0.600-0.799 | ±0.008 | 0.008 |

| 0.800-0.999 | ±0.008 | 0.008 |

| 1.00-1.20 | ±0.009 | 0.009 |

| 1.20-1.40 | ±0.009 | 0.009 |

| 1.40-1.60 | ±0.010 | 0.010 |

| 1.60-1.80 | ±0.010 | 0.010 |

| 1.80-2.00 | ±0.010 | 0.010 |

| 2.00-2.50 | ±0.012 | 0.012 |

| 2.50-3.00 | ±0.015 | 0.015 |

| 3.00-4.00 | ±0.020 | 0.020 |

| 4.00-5.00 | ±0.020 | 0.020 |

Mechanical Properties

|

Symbol |

Diameter (mm) |

Grade |

Tensile strength (kgf/mm2) |

Elongation(%) |

Reduction of Area rate(%) |

|

WSA |

0.8 ~ 2.0 |

STS XM-7 |

49~64 |

≥30 |

≥70 |

|

2.0 ~ 5.5 |

STS XM-7 |

45~60 |

≥40 |

≥70 |

|

|

STS 304HC, 304L |

52~67 |

≥40 |

≥70 |

||

|

WSB |

0.8 ~ 2.0 |

STS XM-7 |

51~69 |

≥20 |

≥65 |

|

STS 430 |

51~71 |

|

≥65 |

||

|

2.0 ~ 17.0 |

STS XM-7 |

46~64 |

≥25 |

≥65 |

|

|

STS 304HC, 304L |

54~72 |

≥25 |

≥65 |

||

|

STS 430 |

46~61 |

≥10 |

≥65 |

Chemical Composition

|

material |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

|

STS304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

8.00 ~ 10.50 |

18.00 ~ 20.00 |

- |

|

STS304L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

9.00 ~ 13.00 |

18.00 ~ 20.00 |

- |

|

STS316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

10.00 ~ 14.00 |

16.00 ~ 18.00 |

2.00 ~ 3.00 |

|

STS316L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

12.00 ~ 15.00 |

16.00 ~ 18.00 |

2.00 ~ 3.00 |

|

STS410 |

≤0.15 |

≤1.00 |

≤1.00 |

≤0.040 |

≤0.030 |

11.50 ~ 13.50 |

- |

- |

|

STS420J1 |

0.16 ~ 0.25 |

≤1.00 |

≤1.00 |

≤0.040 |

≤0.030 |

12.00 ~ 14.00 |

- |

- |

|

STS420J2 |

0.26 ~ 0.40 |

≤1.00 |

≤1.00 |

≤0.040 |

≤0.030 |

12.00 ~ 14.00 |

- |

- |

|

STS430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.030 |

16.00 ~ 18.00 |

- |

- |

Process of production

The production process of martensitic stainless steel is as follows: hot rolling roil - annealing – alkali immersion – rinsing – pickling – coating – wire drawing – decoating – finished product inspection – packaging

Austenitic stainless steel wire production process: hot rolling coil – solution treatment – alkali immersion – rinsing – pickling – coating – wire drawing – decoating – neutralization – finished product inspection – packaging

Packing and Transportation

the standard sea packaging of stainless steel wire

Standard export shipping package:

Woven bag + packing belt;

Customize the packaging according to your requirements (accept printing logo or other content on the packaging);

Other special packaging will be designed according to customer requirements;

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

FAQ

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.

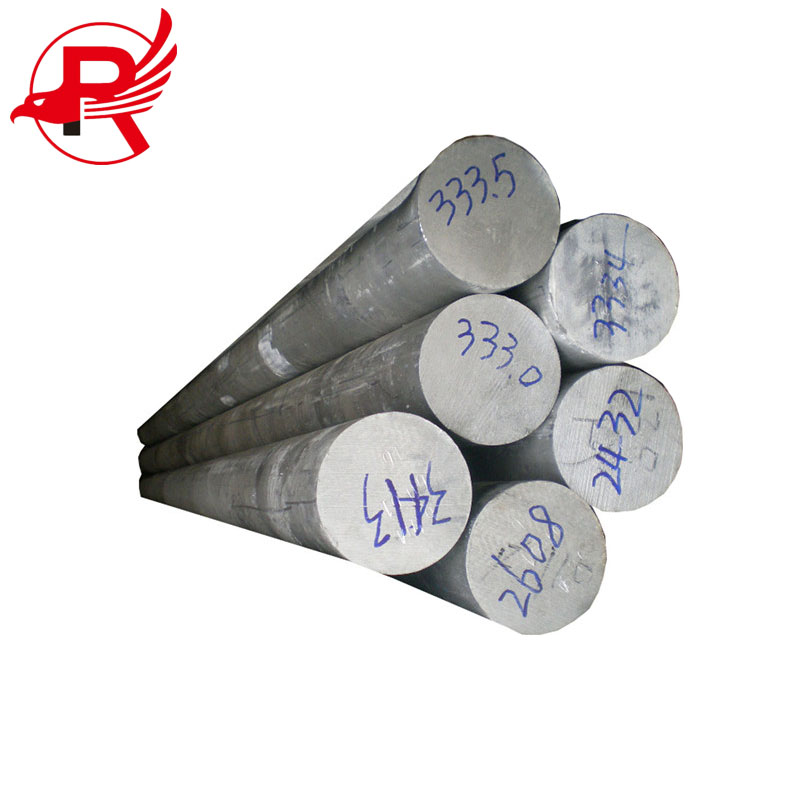

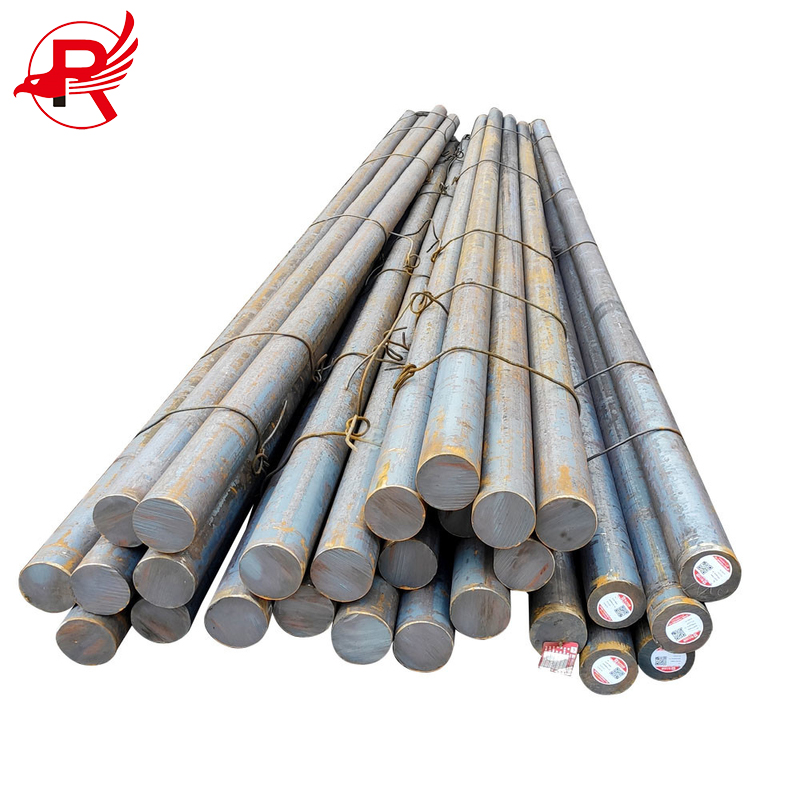

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Top Suppliers 304 Stainless Steel Round Bar - Factory Price 304 316 321 Stainless Steel Wire Rods – Royal Group , The product will supply to all over the world, such as: Singapore, Croatia, Mombasa, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.