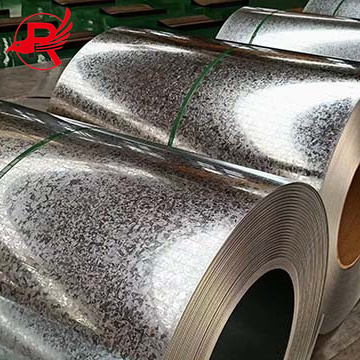

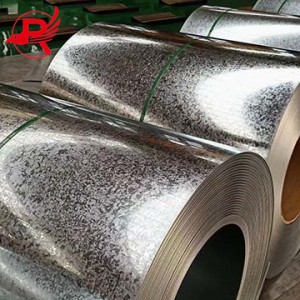

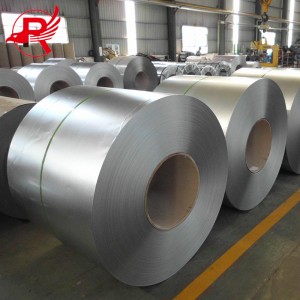

High Quality Galvanized Carbon Steel Coil 0.12mm-6mm Thick Steel Coil

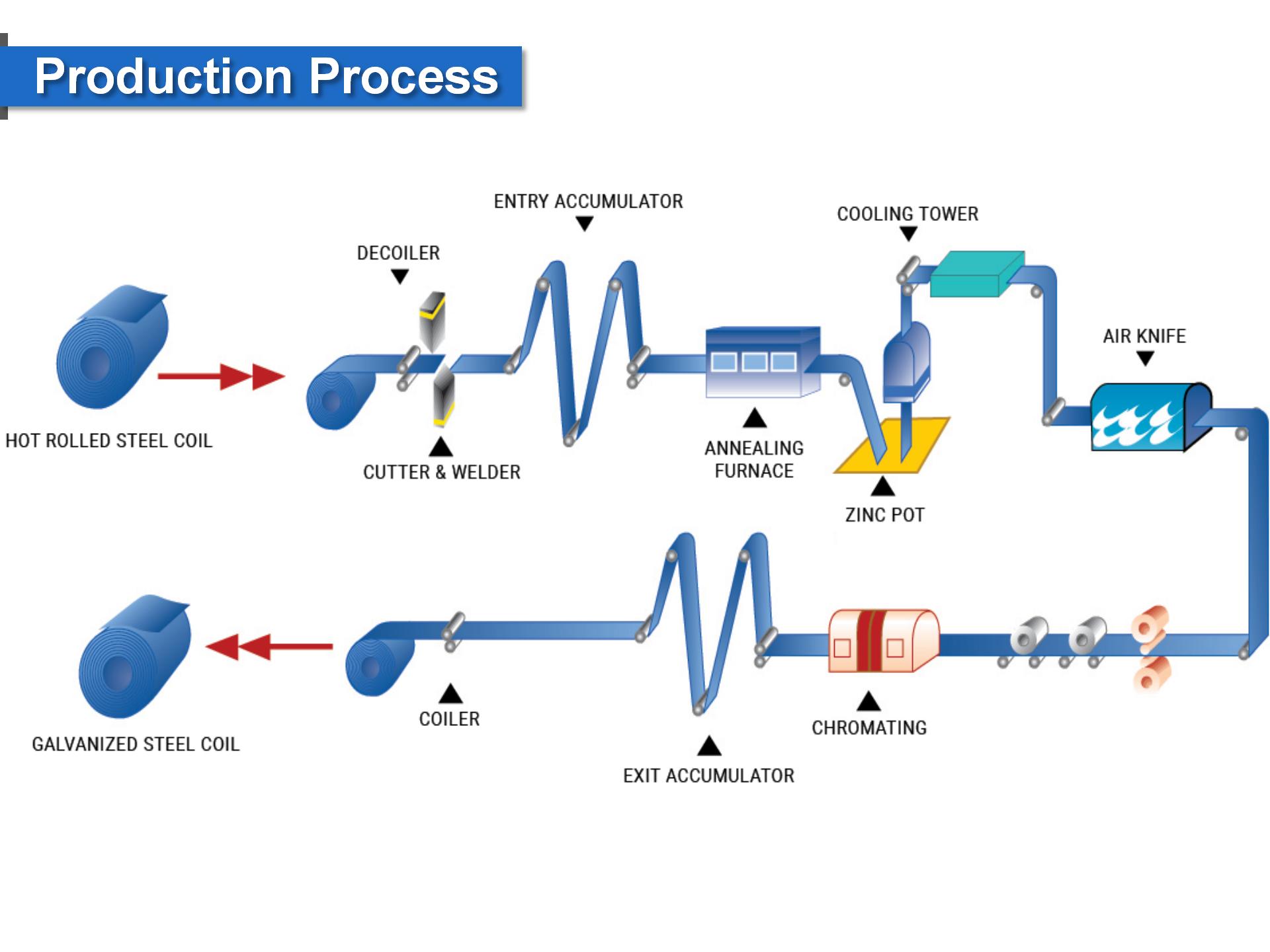

Galvanized coil, a thin steel sheet that is dipped into the molten zinc bath to make its surface adhere to a layer of zinc. At present, it is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously dipped in the bath with melted zinc to make galvanized steel plate; Alloyed galvanized steel sheet. This kind of steel plate is also made by hot dip method, but it is heated to about 500 ℃ immediately after being out of the tank, so that it can form an alloy coating of zinc and iron. This galvanized coil has good coating tightness and weldability. Galvanized coils can be divided into hot-rolled galvanized coils and cold-rolled hot-rolled galvanized coils, which are mainly used in construction, household appliances, automobiles, containers, transportation and household industries. In particular, steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries. The demand of construction industry and light industry is the main market of galvanized coil, which accounts for about 30% of the demand of galvanized sheet.

1. Corrosion Resistance: Galvanizing is an economical and effective rust prevention method that is often used. About half of the world's zinc production is used for this process. Zinc not only forms a dense protective layer on steel surface, but also has cathodic protection effect. When the zinc coating is damaged, it can still prevent the corrosion of iron based materials through cathodic protection.

2. Good Cold Bending and Welding Performance: low carbon steel is mainly used, which requires good cold bending, welding performance and certain stamping performance

3. Reflectivity: high reflectivity, making it a thermal barrier

4. The Coating Has Strong Toughness, and the zinc coating forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

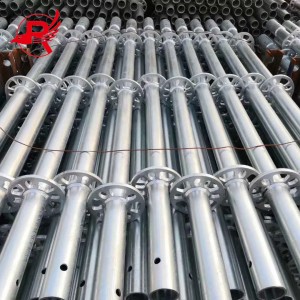

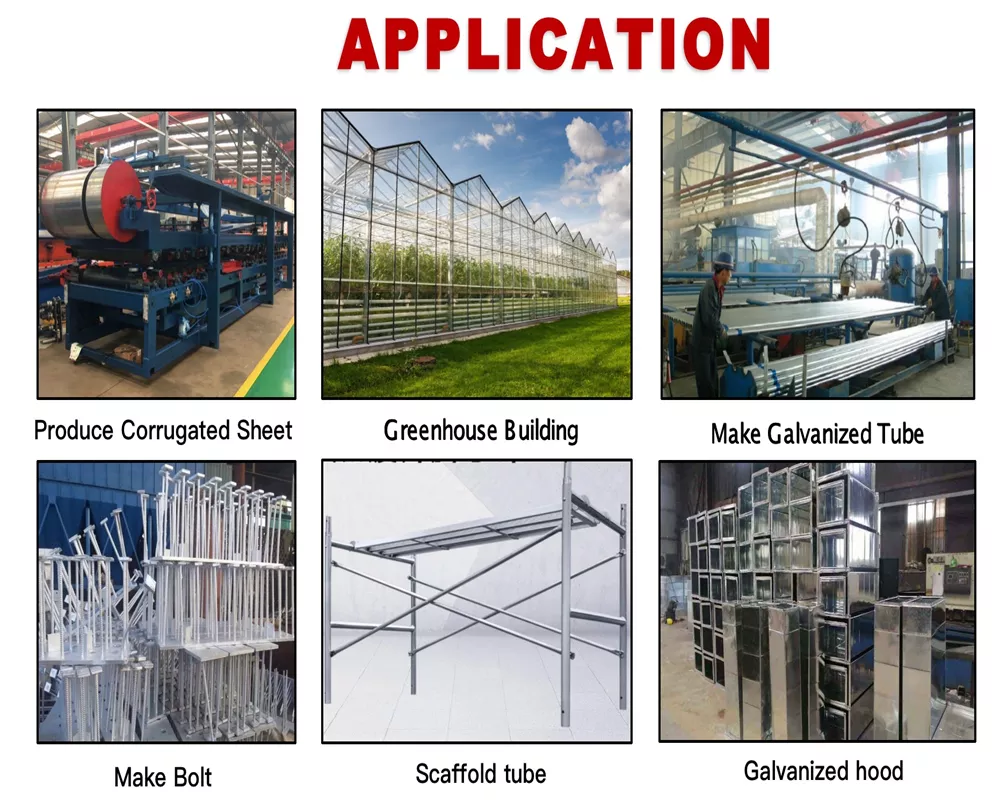

Galvanized steel coil products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries. The construction industry is mainly used to manufacture anti-corrosion roof panels and roof gratings for industrial and civil buildings; In light industry, it is used to manufacture household appliance shells, civil chimneys, kitchen appliances, etc. In automobile industry, it is mainly used to manufacture corrosion resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; It is mainly used for the storage and transportation of materials and packaging tools.

|

Name

|

Hot sale Shandong DX51D Z100 GI hot galvanized steel coil

|

|

Standard

|

AISI,ASTM,GB,JIS

|

|

Material

|

SGCC,SGCH,G550,DX51D,DX52D,DX53D

|

|

Brand

|

Shandong Sino Steel

|

|

Thickness

|

0.12-4.0mm

|

|

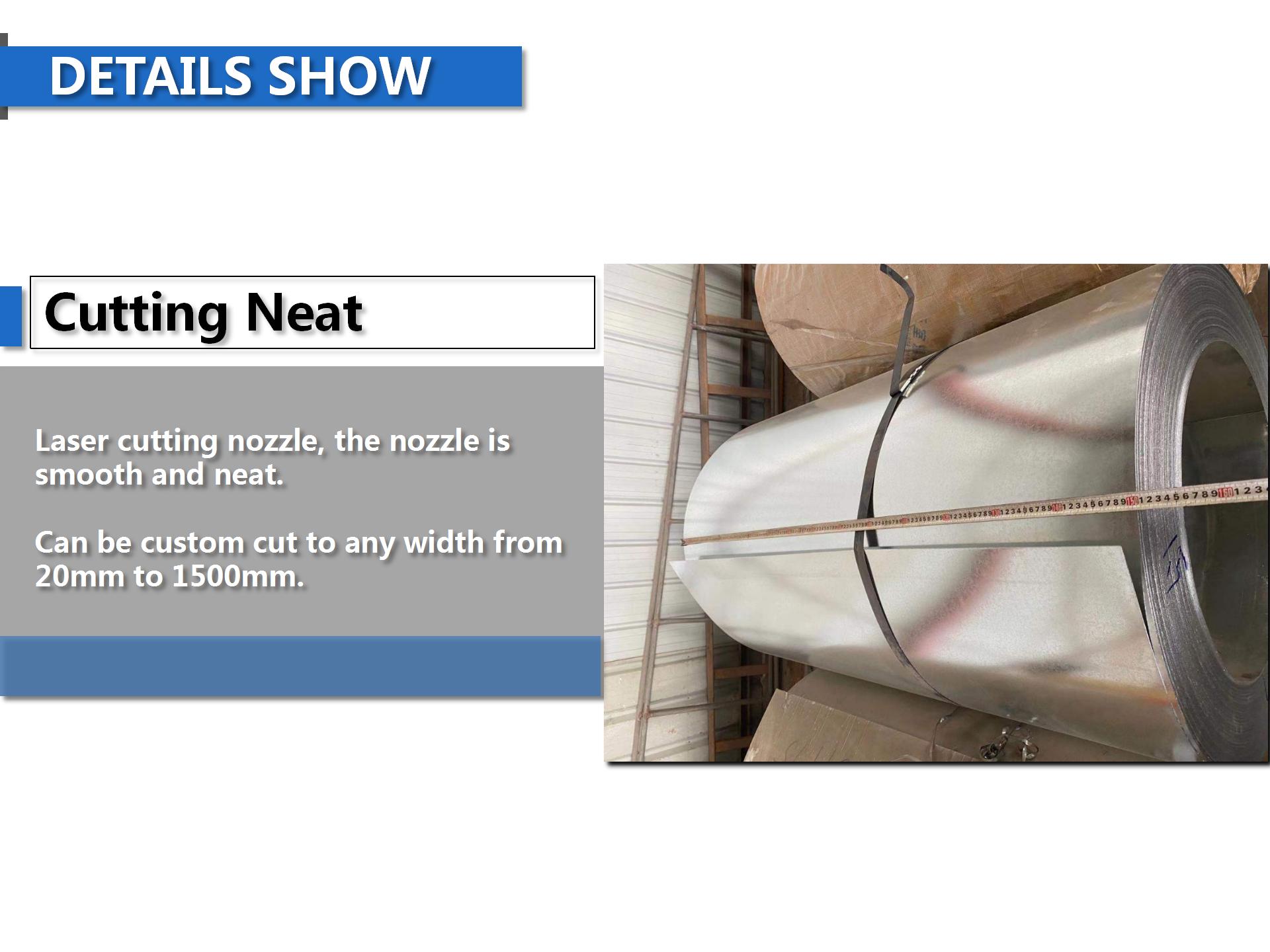

Width

|

600-1500 mm

|

|

Tolerance

|

+/-0.02mm

|

|

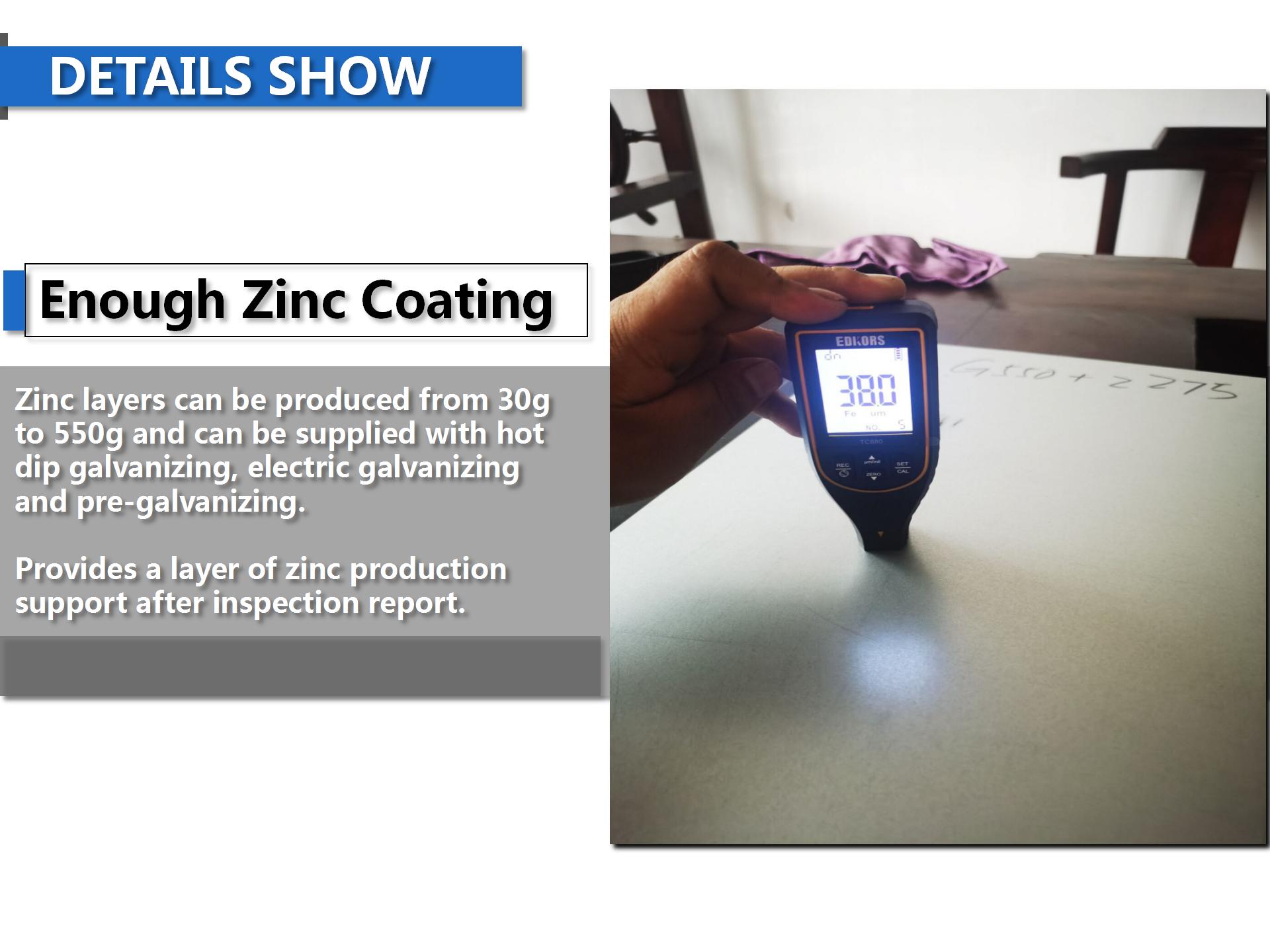

Zinc coating

|

40-600g/m2

|

|

Surface treatment

|

Unoil,dry,chromate passivated, non-chromate passivated

|

|

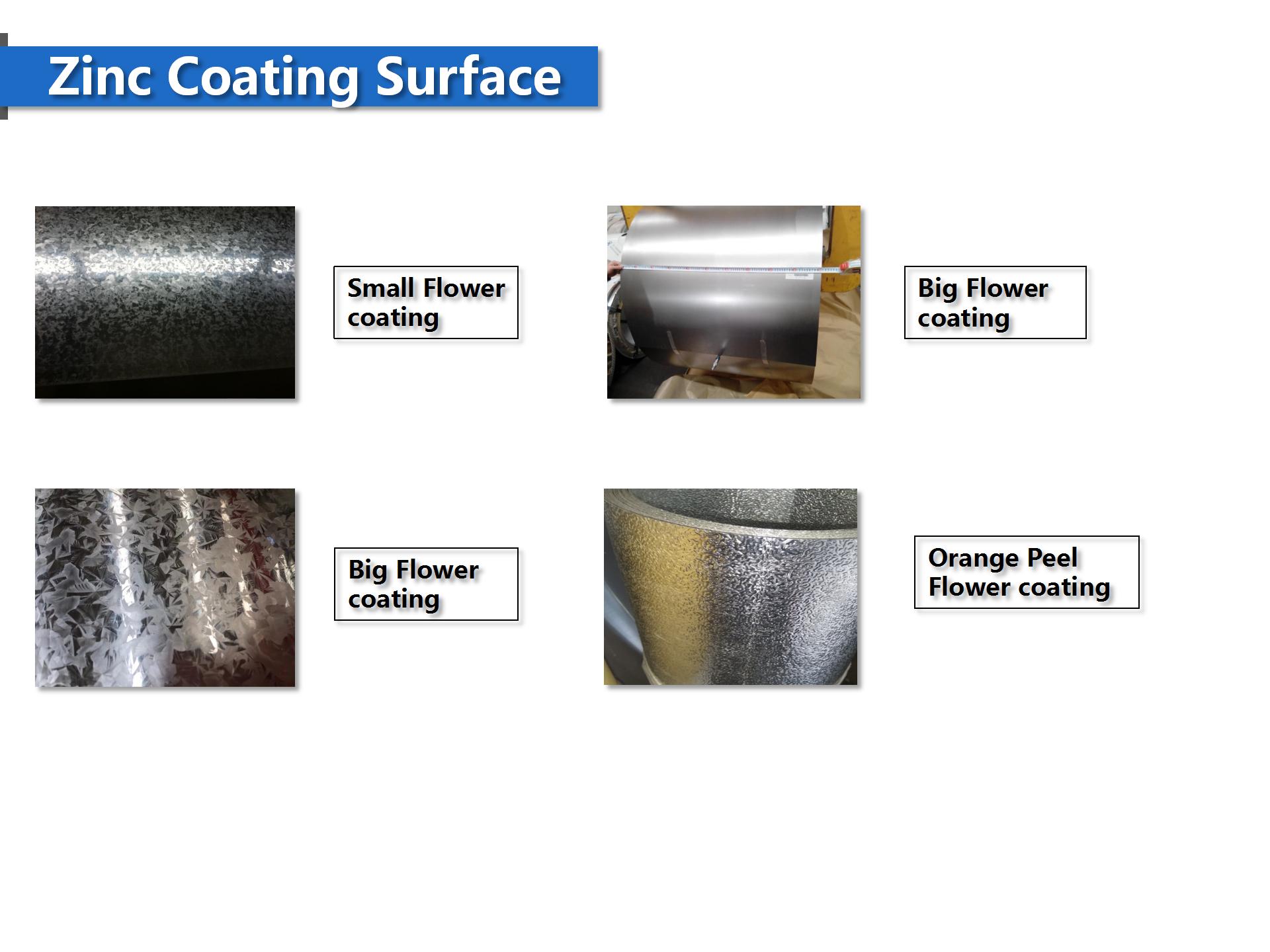

Spangle

|

Regular spangle,minimal spangle, zero spangle,big spangle

|

|

Coil ID

|

508mm/610mm

|

|

Coil Weight

|

3-8 tons

|

|

Technique

|

Hot rolled, cold rolled

|

|

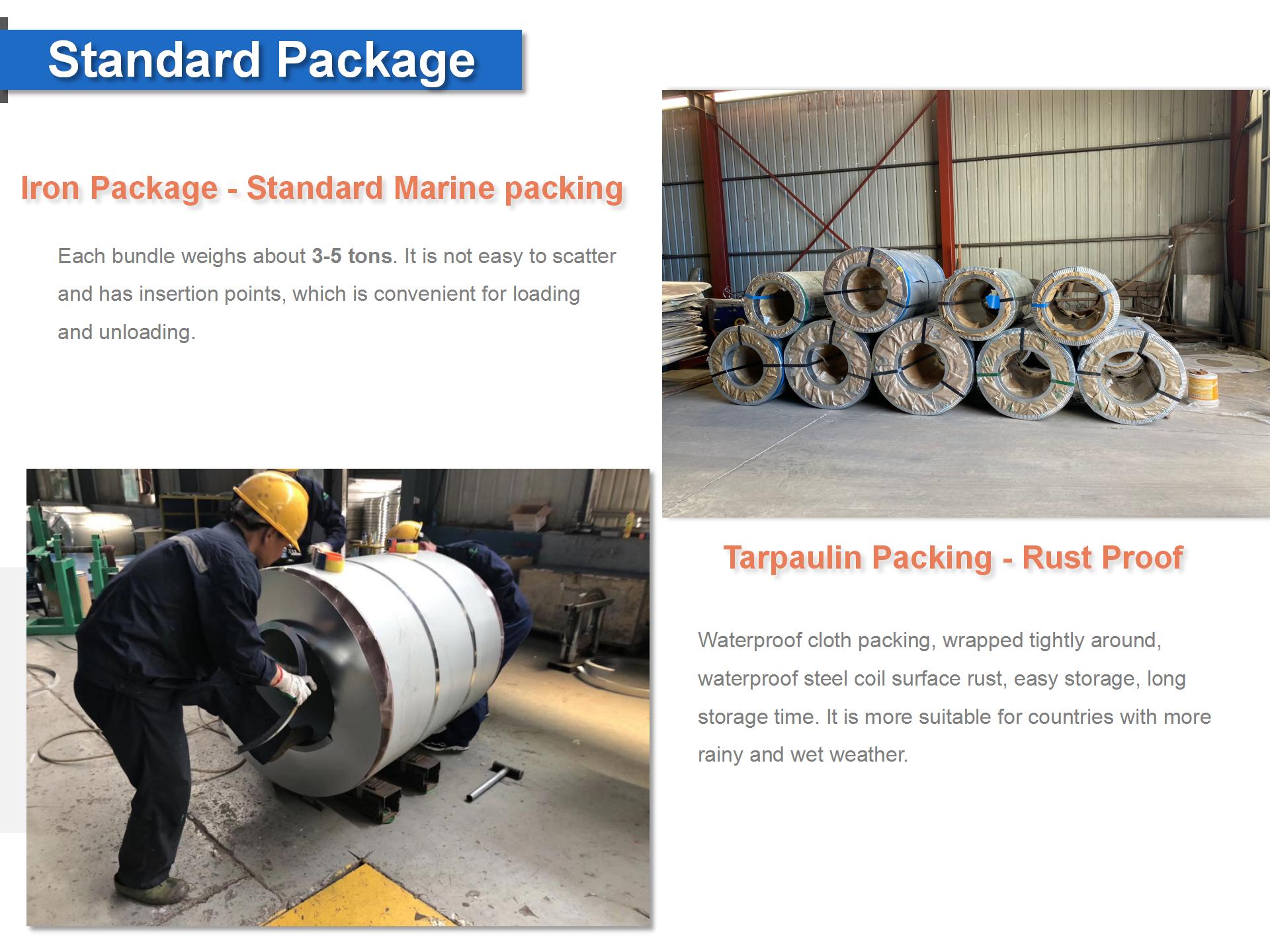

Package

|

Standard seaworthy export packing:

3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve |

|

Certification

|

ISO 9001-2008,SGS,CE,BV

|

|

MOQ

|

22 TONS (in one 20ft FCL)

|

|

Delivery

|

15-20 days

|

|

Monthly Output

|

30000 tons

|

|

Description

|

Galvanized steel is mild steel with a coating of zinc. The zinc protects the steel by providing cathodic protection to the exposed steel, so should the surface be damaged the zinc will corrode in preference to the steel. Zinc steel is one of the most widely used products, used extensively in the building sector, automotive, agricultural and other areas where the steel needs to be protected from corrosion

|

|

Payment

|

T/T, LC, Kun Lun Bank,Western Union, Paypal

|

|

Remarks

|

Insurance is all risks and accept the third party test

|

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact

us for further information.

2. Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 5-20 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5. What kinds of payment methods do you accept?

30% in advance by T/T, 70% will be before shippment basic on FOB; 30% in advance by T/T, 70% against the copy of BL basic on CIF.