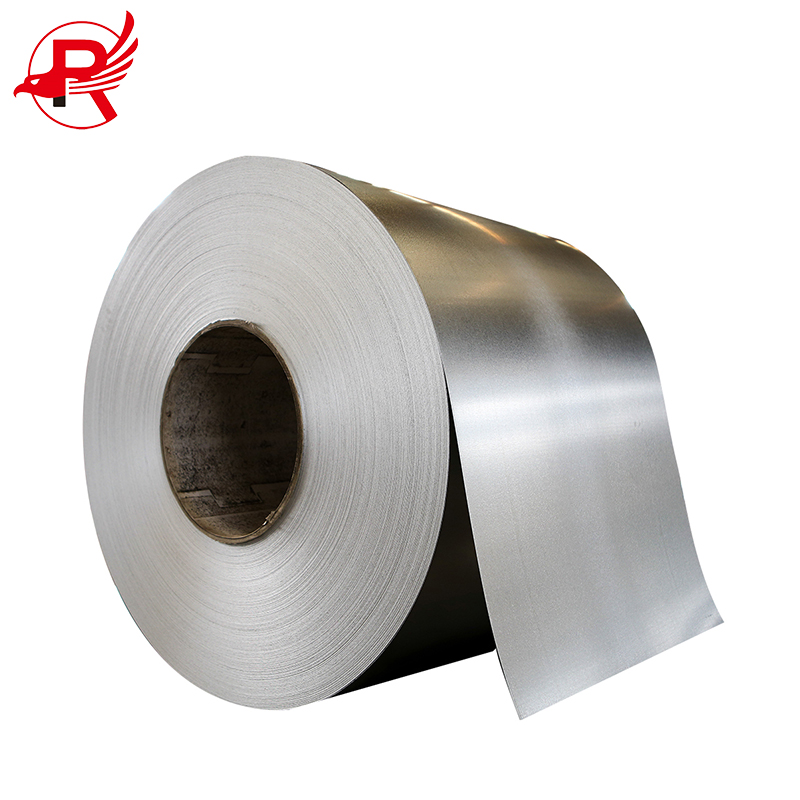

High Quality G250+AZ150 Aluzinc Galvalume Steel Coil

| Product Name | DX51D AZ150 0.5mm thickness aluzinc/galvalume/zincalume Steel Coil |

| Material | DX51D/ 52D/ 53D/ 54D/ 55D/ DX56D+Z/ SGCC |

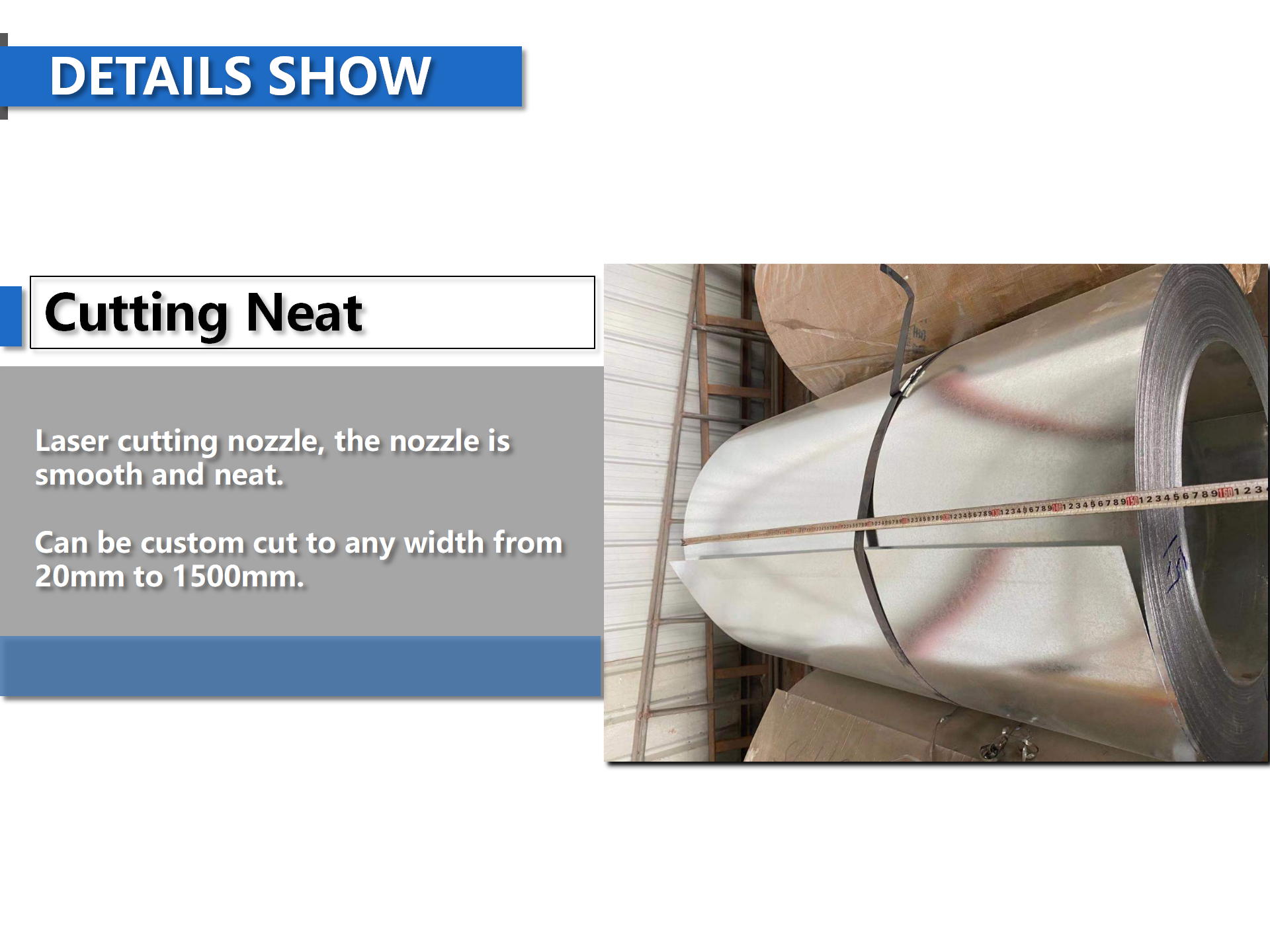

| Thickness Range | 0.15mm-3.0mm |

| Standard Width | 1000mm 1219mm 1250mm 1500mm 2000mm |

| Length | 1000mm 1500mm 2000mm |

| Coil Diameter | 508-610mm |

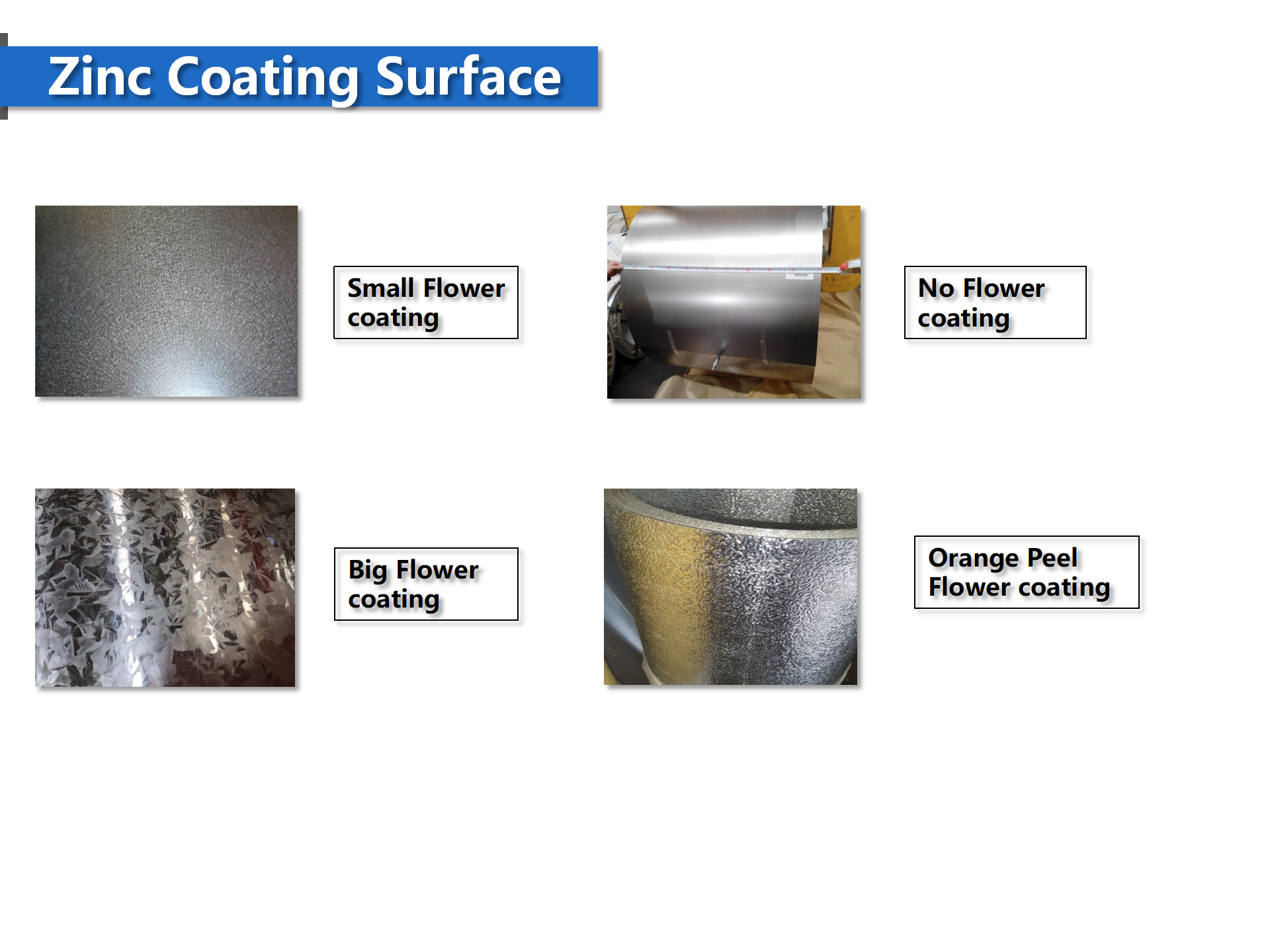

| Spangle | Regular,zero,minimized,big,skin pass |

| Weight per roll | 3-8ton |

| Product Name | Galvalume steel coil |

| Material | Cold rolled Zinc-Alu-zinc Hot Dipped steel coil/sheet |

| Surface Treatment | Filmed,Emboss,Wrinkle,Printing |

| Standard | DIN GB ISO JIS BA ANSI |

| Grade | GB/T-12754 JIS G 3312 EN 10169 ASTM A755 |

| Brand | CAMELSTEEL |

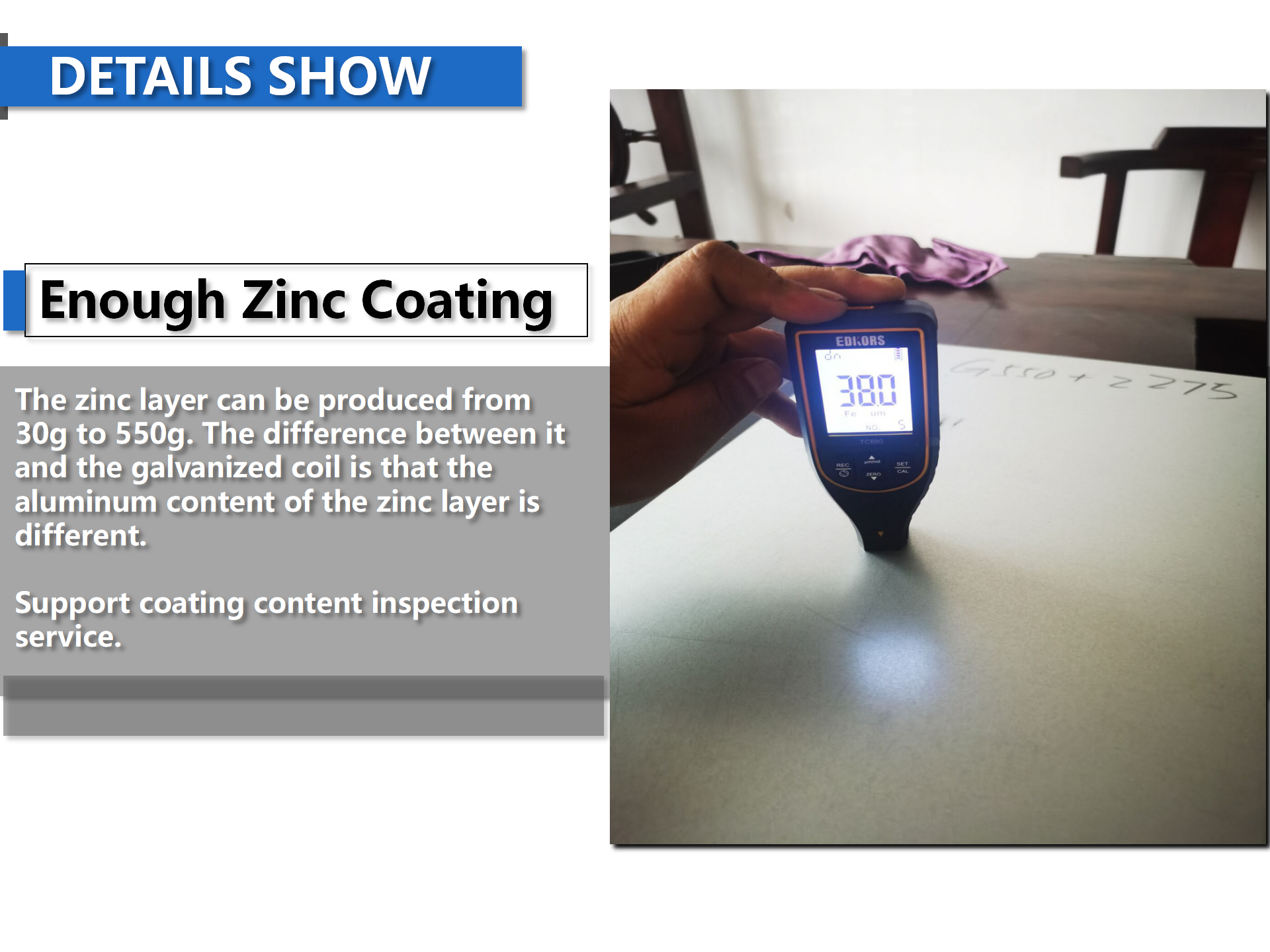

| Zinc/Aluzinc coating | Zn 40g/sm-275g/sm Alu-zinc 40-150g/sm |

| Coil weight | 3-5tons or As your requirement |

| Painting | Prime : 5μm Top coating : 7--20μm |

| Back coating | 7 --15μm |

| Color | As RAL or your requirement |

| Hardness | CQ/FH/As your requirement (G300-G550) |

| Surface Treatment | With plastic film , Chromated, Wrinkle, Matt, Decorate, Sand surface, Highlight. |

| Application | building industry,wall cladding,roofing sheet,roller shutter |

Buildings: roofs, walls, garages, sound insulation walls, pipes, modular houses, etc

Automobile: muffler, exhaust pipe, wiper accessories, fuel tank, truck box, etc

Household appliances: refrigerator backplane, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electrical cabinet

Agriculture: pig house, chicken house, granary, greenhouse pipes, etc

Others: heat insulation cover, heat exchanger, dryer, water heater and other chimney pipes, oven, illuminator and fluorescent lamp shade.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

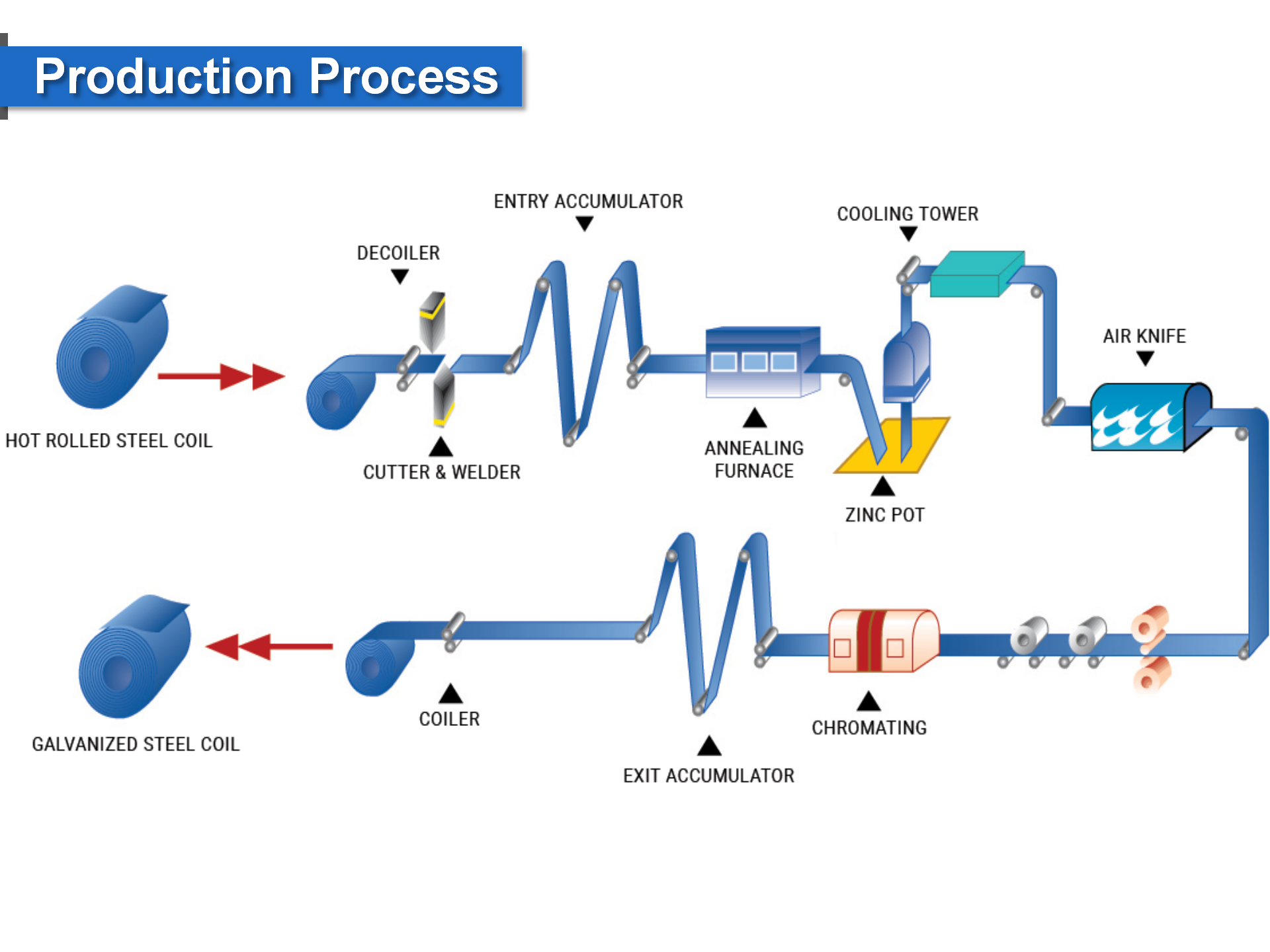

The production process of galvalume coated steel coil usually involves several stages, including:

1. Cleaning and preparation: The process begins with cleaning the raw steel coil to remove any dirt, oil or rust. The coils are then dried and pre-treated with chemicals to improve their adhesion to the coating.

2. Coating: The pretreated coils are coated with a mixture of aluminum (55%), zinc (43.5%) and silicon (1.5%) in a continuous hot-dip process. The mixture forms a galvanized coating on steel surfaces with excellent corrosion resistance.

3. Cooling: After the coating process, the coil is cooled in a controlled environment to cure the coating and improve its adhesion to the steel surface.

4. Finishing: Then the galvalume coil is trimmed, leveled and cut to size. They are also quality checked to ensure they meet the required specifications for thickness, width and surface finish.

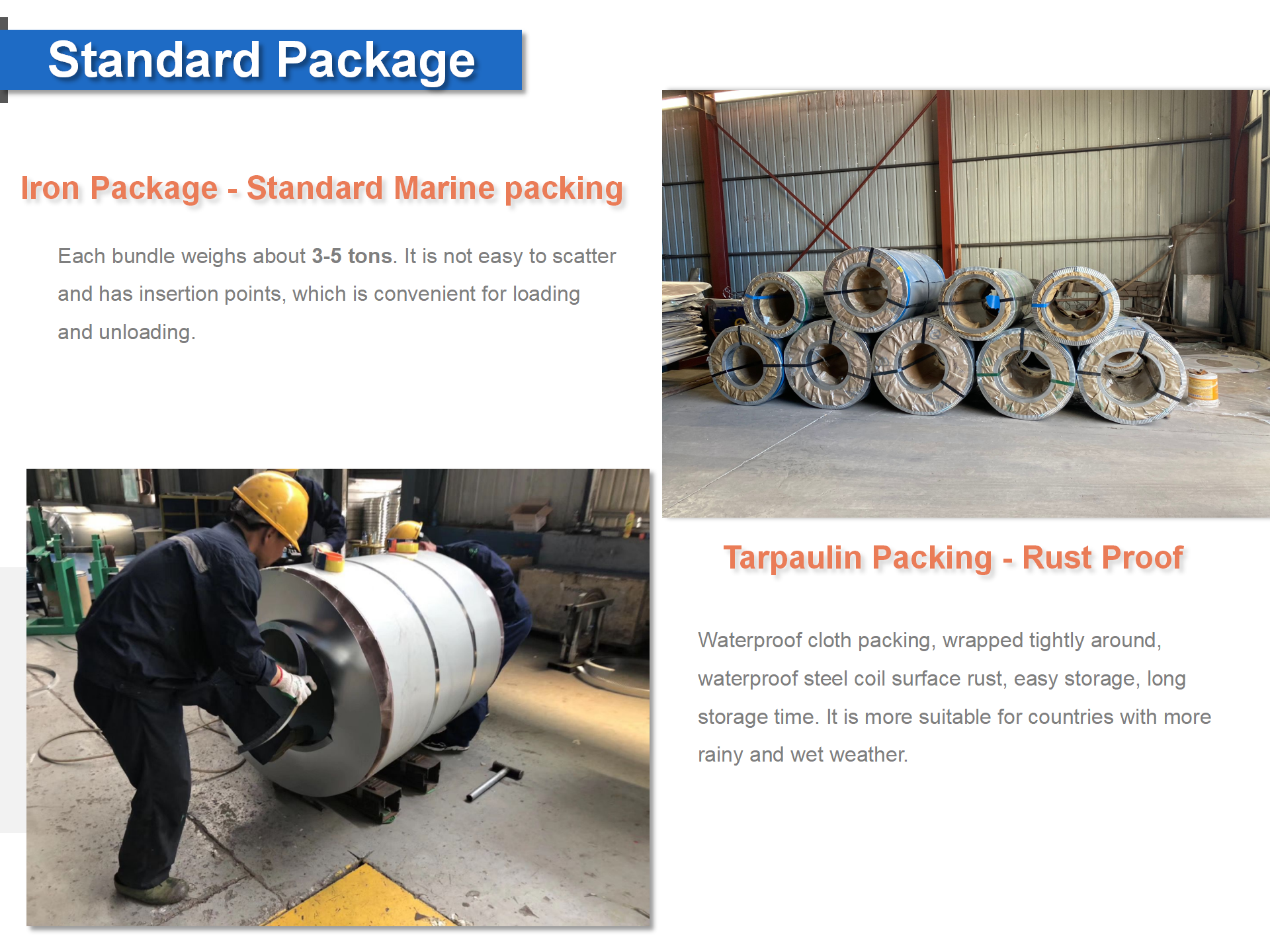

5. Packaging and Shipping: The finished galvalume coil is then packaged and shipped to customers for various applications such as roofing, siding, and automotive manufacturing.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Daqiuzhuang Village, Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.