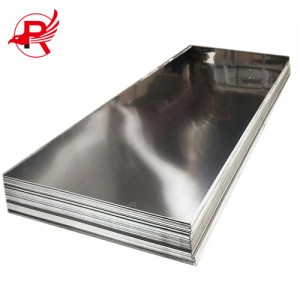

High Quality ASTM 347 Heat Resistant Stainless Steel Sheet

| Product Name | 309 310 310S Heat Resistant Stainless Steel Plate For Industrial Furnaces And Heat Exchangers |

| Length | as required |

| Width | 3mm-2000mm or as required |

| Thickness | 0.1mm-300mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness Tolerance | ±0.01mm |

| Material | 309 ,310,310S,316,347,431,631, |

| Application | It is widely used in construction materials, chemicals, high-temperature applications, medical facilities, food industry, agriculture, and ship parts. It is also suitable for food and beverage packaging, kitchen tools, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs, and screens. |

| MOQ | 1 ton , We can accept sample order. |

| Shipment Time | Within 7-15 workdays after receiving deposit or L/C |

| Export Packing | Waterproof paper and steel belt packaging. Standard export sea freight packaging. Suitable for various transportation, or transported as required. |

| Capacity | 250,000 tons/year |

The heat resistance of stainless steel plates is crucially determined by their composition, which typically includes chromium, nickel, and other alloying elements.

These elements provide excellent oxidation resistance and corrosion resistance in high-temperature environments, allowing the plates to maintain their structural integrity and mechanical properties even after prolonged exposure to high temperatures.

There are many grades of heat-resistant stainless steel plates, such as 310S, 309S, and 253MA, each with different heat resistance capabilities under varying temperature ranges and environmental conditions. These plates also come with various surface treatments, thicknesses, and sizes available, making them suitable for application in various industrial and commercial fields.

Overall, heat-resistant stainless steel plates are key components in industries such as aerospace, petrochemicals, and power generation, where the ability to withstand high temperatures is crucial for the performance and longevity of equipment.

Stainless steel plates are widely used in multiple industries due to their excellent corrosion resistance, high strength, and versatility. The main applications of stainless steel plates include:

1. Construction: Stainless steel plates are used in the construction of buildings, bridges, and other structures because of their durability, strength, and aesthetic appeal.

2. Kitchen Equipment: Stainless steel plates are widely used to manufacture kitchen equipment such as sinks, countertops, cabinets, and appliances due to their corrosion resistance, stain resistance, and heat resistance.

3. Automotive: Due to their high strength and corrosion resistance, stainless steel plates are used to manufacture automotive components such as exhaust systems, fuel tanks, and body panels.

4. Medical: Stainless steel plates are used in the medical industry to manufacture surgical instruments, implants, and equipment because of their excellent biocompatibility and corrosion resistance.

5. Aerospace: Stainless steel sheets are used in the aerospace industry for the manufacturing of aircraft and spacecraft components due to their high strength, durability, and resistance to extreme temperatures.

6. Energy: Due to their corrosion resistance and high-temperature endurance, stainless steel sheets are utilized in the energy sector for the manufacturing of pipes, tanks, and other equipment.

7. Consumer Goods: Stainless steel sheets are used in a variety of consumer products, such as home appliances, furniture, and jewelry, because of their aesthetic appeal and durability.

Note:

1. Get free samples, 100% after-sales quality support guaranteed, and you can use any payment method; 2. Customized to provide all other specifications of round carbon steel pipes (OEM & ODM) according to your requirements! You can obtain factory prices through ROYAL GROUP.

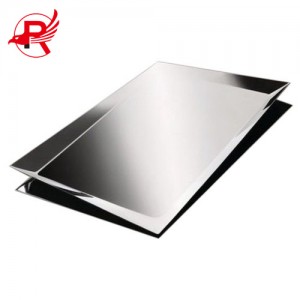

Through different cold-rolling methods and the subsequent surface reprocessing, the surface finish of stainless steel plates can have many different types.

The surface processing of stainless steel sheet have NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright and other surface finishes, etc.

NO.1: The No. 1 surface refers to the surface obtained after hot rolling stainless steel sheets followed by heat treatment and pickling. The purpose is to remove the black oxidation scale generated during the hot rolling and heat treatment processes through pickling or similar treatments. This is the No. 1 surface treatment. The No. 1 surface appears silver-white and matte. It is mainly used in high-temperature and corrosion-resistant industries where surface gloss is not required, such as the alcohol industry, chemical industry, and large containers.

2B: The characteristic of the 2B surface is that it is different from the 2D surface, using a smooth roller for smoothing treatment, resulting in a shinier finish than the 2D surface. The surface roughness Ra value measured by the instrument is between 0.1 and 0.5 μm, which is the most common type of processing. This type of stainless steel sheet surface has the widest range of applications, suitable for general use, and is widely used in industries such as chemical, papermaking, petroleum, and medical, and can also be used as building curtain walls.

TR Hard Surface: TR stainless steel is also known as hard steel. Its representative steel grades are 304 and 301, which are commonly used for products that require high strength and hardness, such as railway vehicles, conveyor belts, springs, and washers. The principle is to utilize the work-hardening characteristics of austenitic stainless steel to enhance the strength and hardness of the steel plate through cold processing methods such as rolling. Hard materials use several to several dozen percentage points of light rolling to replace the slight flatness of the 2B base surface, and no annealing is performed after rolling. Therefore, the TR hard surface of hard materials refers to the cold-rolled surface after rolling.

Rerolled Bright 2H: After the rolling process, the stainless steel sheet will undergo bright annealing treatment. The strip steel can be rapidly cooled through a continuous annealing line. The speed of the stainless steel sheet on the production line is about 60 to 80 meters per minute. After this step, the surface treatment will provide a 2H bright finish re-rolling.

No. 4: The surface polishing effect of No. 4 is brighter and more refined than that of No. 3. It is achieved by polishing cold-rolled stainless steel sheets based on 2D or 2B surfaces, using abrasive belts with a grain size of 150-180#. The instrument measured a surface roughness Ra value of 0.2 to 1.5μm. The NO.4 surface is widely used in restaurant and kitchen equipment, medical devices, architectural decoration, containers, and more.

HL: The HL surface is usually referred to as a hairline finish. The Japanese JIS standard specifies the use of 150-240# sanding belts for polishing to achieve a continuous hairline patterned abrasive surface. In China's GB3280 standard, the related provisions are relatively vague. HL surface treatment is mainly used for architectural decoration, such as elevators, escalators, and facades.

No. 6: The surface of No. 6 is based on the surface of No. 4, further polished using a Tampico brush or abrasives with a grain size of W63 as specified by standard GB2477. This surface has a good metallic luster and a soft texture. It has weak reflections and does not reflect images. Due to this excellent characteristic, it is very suitable for making building curtain walls and architectural edge decorations, and it is also widely used for kitchen utensils.

BA: BA is a surface obtained after bright heat treatment through cold rolling. Bright heat treatment is an annealing process conducted in a protective atmosphere, ensuring that the surface is not oxidized to maintain the luster of the cold-rolled surface, followed by slight flattening with high-precision leveling rollers to improve surface brightness. This surface is close to mirror polishing, with a measured surface roughness Ra value of 0.05-0.1μm. The BA surface has a wide range of applications, including kitchen utensils, home appliances, medical equipment, automotive parts, and decorations.

No.8: No.8 is a mirrored finish surface with the highest reflectivity, free of abrasive particles. The stainless steel deep processing industry also refers to it as 8K plate. Generally, BA material is only used as raw material for mirror treatment through grinding and polishing. After mirror treatment, the surface has an artistic feel, thus it is mainly used for architectural entrance decoration and interior decoration.

The standard sea packaging of stainless steel sheet

Standard export sea packaging:

Waterproof paper roll + PVC film + straps + wooden pallet;

Custom packaging according to your requirements (printing logos or other content on the packaging is accepted);

Other special packaging will be designed according to customer requirements.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

Q: Are u a manufacturer?

A: Yes, we are a spiral steel pipe manufacturer located in Daguzhuang Village, Tianjin, China.

Q: Can I have a trial order only several tons?

A:Of course. We can ship your goods through the less than container load (LCL) service.

Q: Do u have payment superiority?

A: For large orders, a letter of credit with a term of 30-90 days is acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.