Good Quality Aluminum Pipe - Best Sale 2024 7075 6061 5052 t651 Aluminum Alloy Round Bar for Aircraft Structure – Royal Group

Good Quality Aluminum Pipe - Best Sale 2024 7075 6061 5052 t651 Aluminum Alloy Round Bar for Aircraft Structure – Royal Group Detail:

Product Detail

|

Product Name |

ASTM B211,ASTM B221, ASTM B531 ETC | |

|

Material |

Aluminum, aluminum alloy2000 Series: 2014A, 2014, 2017, 2024, 2219, 2017, 2017A, 22185000 Series: 5052, 5056, 5154, 5015, 5082, 5754, 5456, 5086, 51826000 Series: 6061, 6060, 6063, 6070, 6181, 6082

7000 Series: 7005, 7020, 7022, 7050, 7075 8000 Series: 8011, 8090 |

|

|

Processing |

Extrusion | |

|

Shape |

Round, Square, Hex, etc. | |

|

Size |

Diameter (mm) | Length (mm) |

| 5mm-50mm | 1000mm-6000mm | |

| 50mm-650mm | 500mm-6000mm | |

|

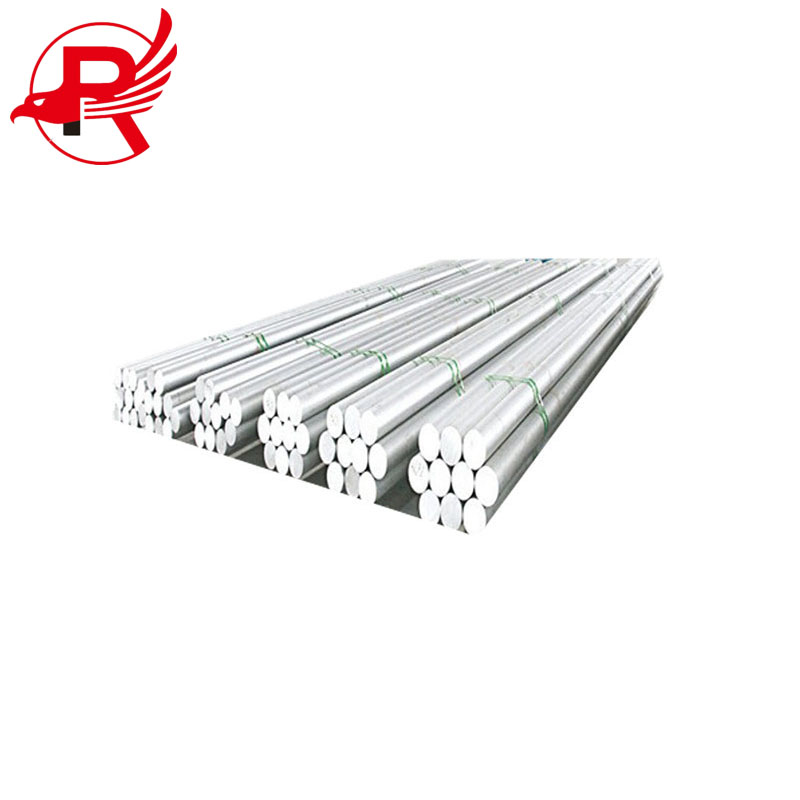

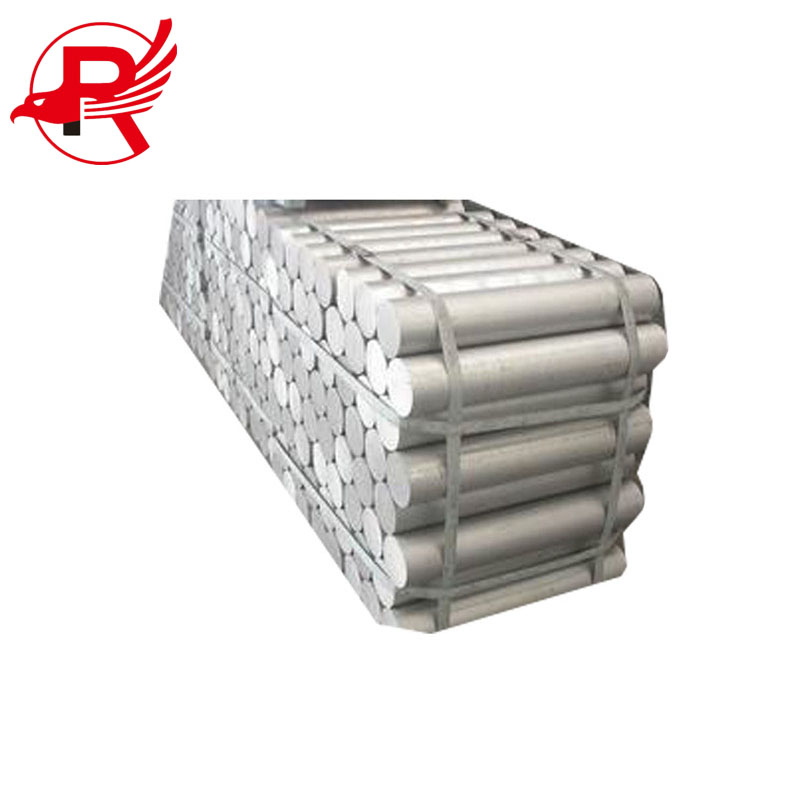

Packing |

Standard export packingPlastic bag or waterproof paperWooden case (custom suffocating free)Pallet | |

|

Property |

Aluminum has a special chemical physical characteristic, not only light weight, firm texture, but have good ductility, electrical conductivity, thermal conductivity, heat resistance and radiation | |

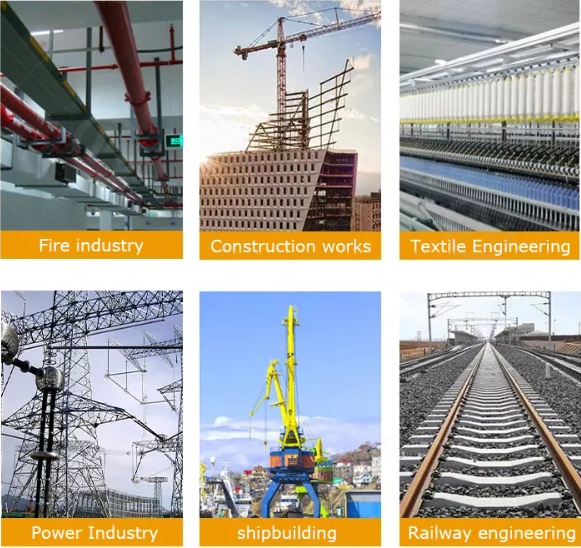

Main Application

Aluminum is non-toxic and can be used in food preparation equipment. Aluminum’s reflective nature is suitable for light fixtures, is non-combustible and so does not burn. Some end uses include transportation, food packaging, furniture, electrical applications, building, construction, machinery and equipment.

Aluminum bar can be used for a variety of applications, including:

- Medical assembly

- Aircraft construction

- Structural components

- Commercial transportation

- Electrical Components

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

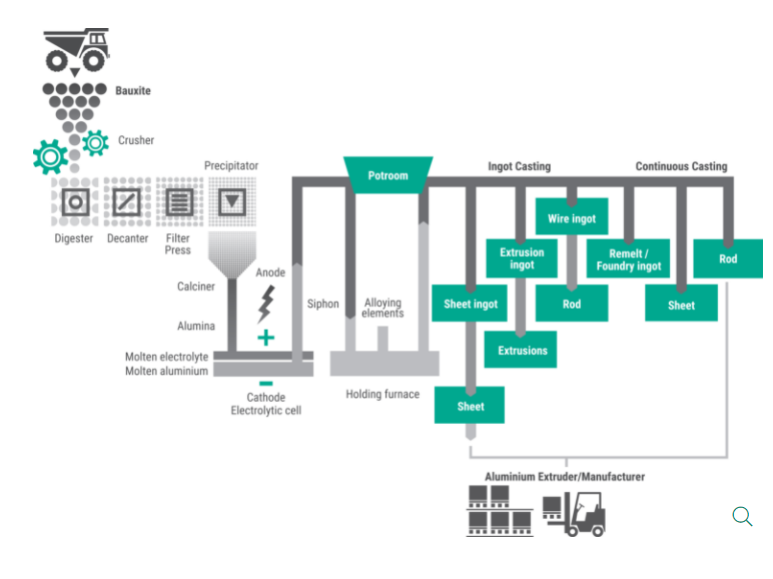

Process of production

The production process of martensitic stainless steel is as follows: hot rolling roil - annealing – alkali immersion – rinsing – pickling – coating – wire drawing – decoating – finished product inspection – packaging

Austenitic stainless steel wire production process: hot rolling coil – solution treatment – alkali immersion – rinsing – pickling – coating – wire drawing – decoating – neutralization – finished product inspection – packaging

product Inspection

Packing and Transportation

Packaging is generally naked, steel wire binding, very strong.

If you have special requirements, you can use rust proof packaging, and more beautiful.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Our Customer

FAQ

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Daqiuzhuang village, Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.

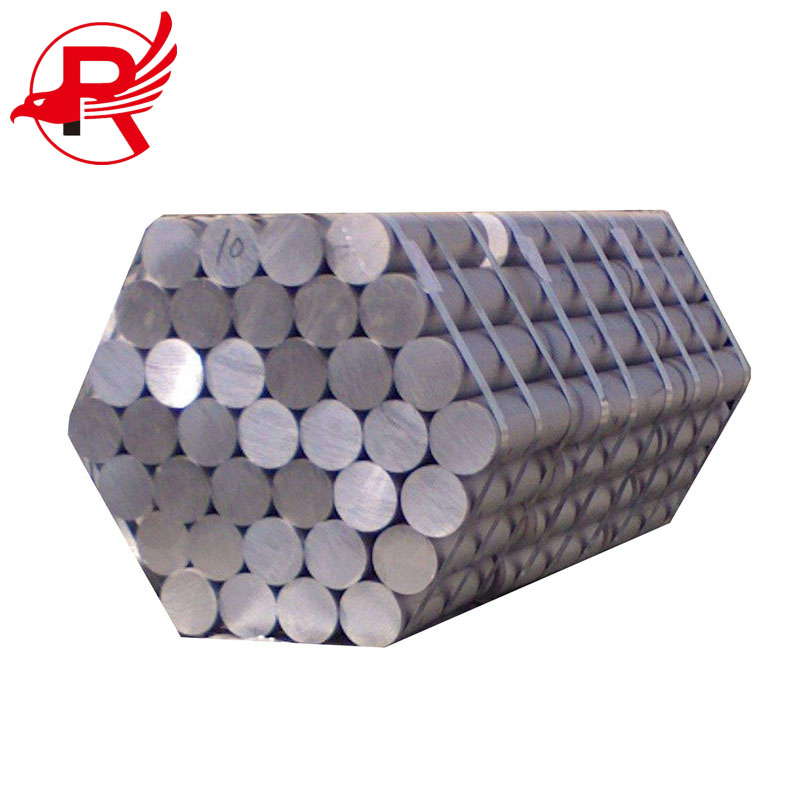

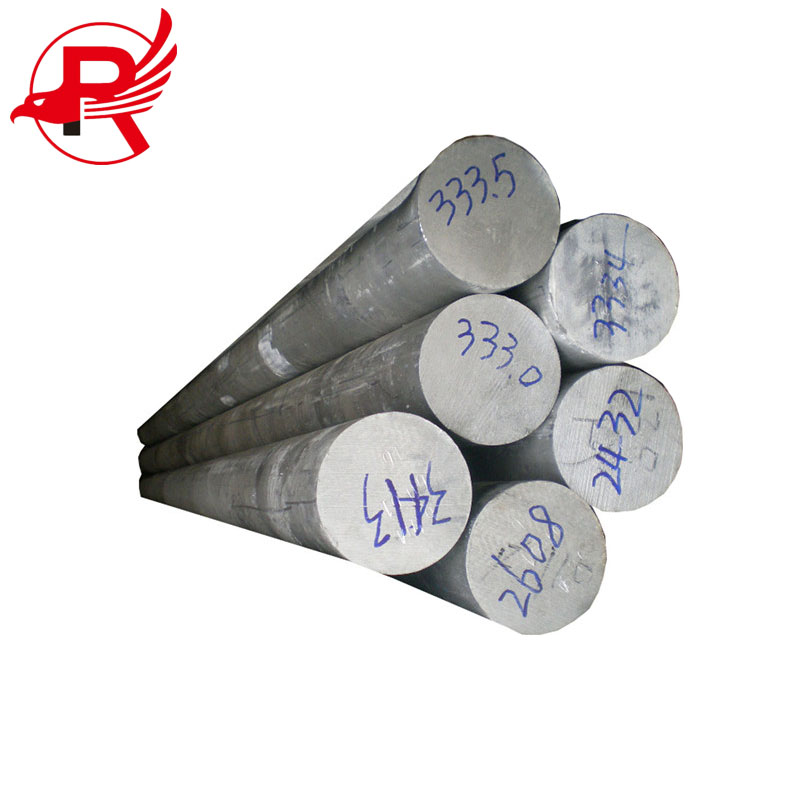

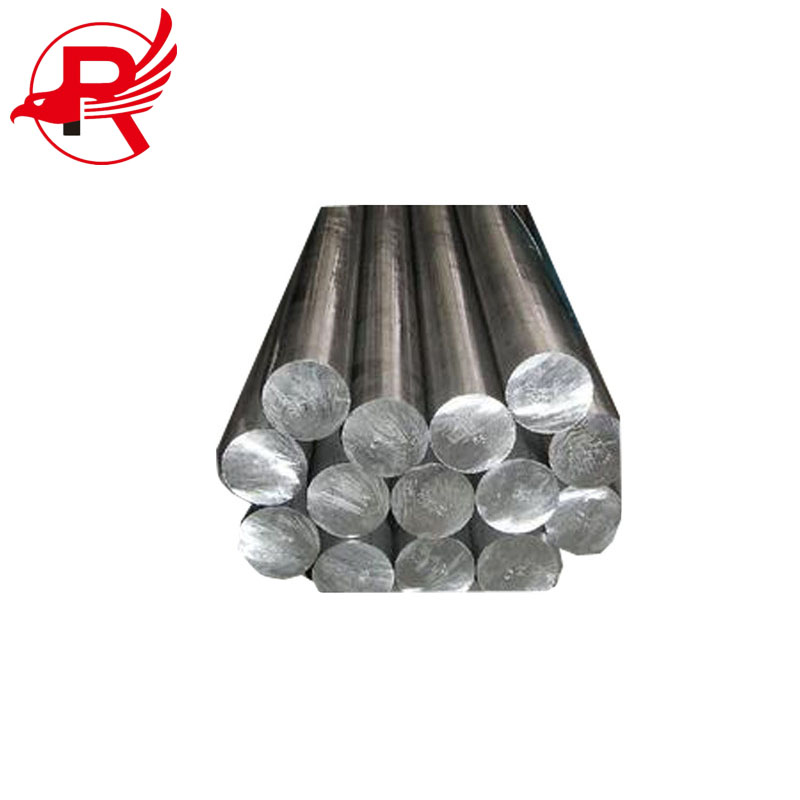

Product detail pictures:

Related Product Guide:

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Good Quality Aluminum Pipe - Best Sale 2024 7075 6061 5052 t651 Aluminum Alloy Round Bar for Aircraft Structure – Royal Group , The product will supply to all over the world, such as: Russia, Tunisia, Jordan, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!