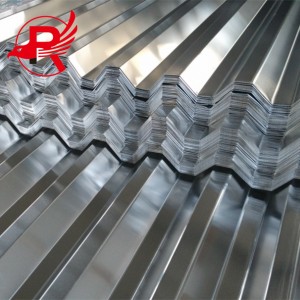

High Qualitydx51d/Dx54D Cold Rolled Colored Painted Galvanized Corrugated Steel Plate/Corrugated Board

|

Standard

|

AiSi, ASTM, BS, DIN, GB, JIS

|

|

Grade

|

DX51D/CGCC/SGHC/SPCC/SGCC

|

|

Model Number

|

All Types

|

|

Technique

|

Cold Rolled/Hot Rolled

|

|

Surface Treatment

|

Coated

|

|

Application

|

Container Plate

|

|

Special Use

|

High-strength Steel Plate

|

|

Width

|

600 - 3600mm or as requirement

|

|

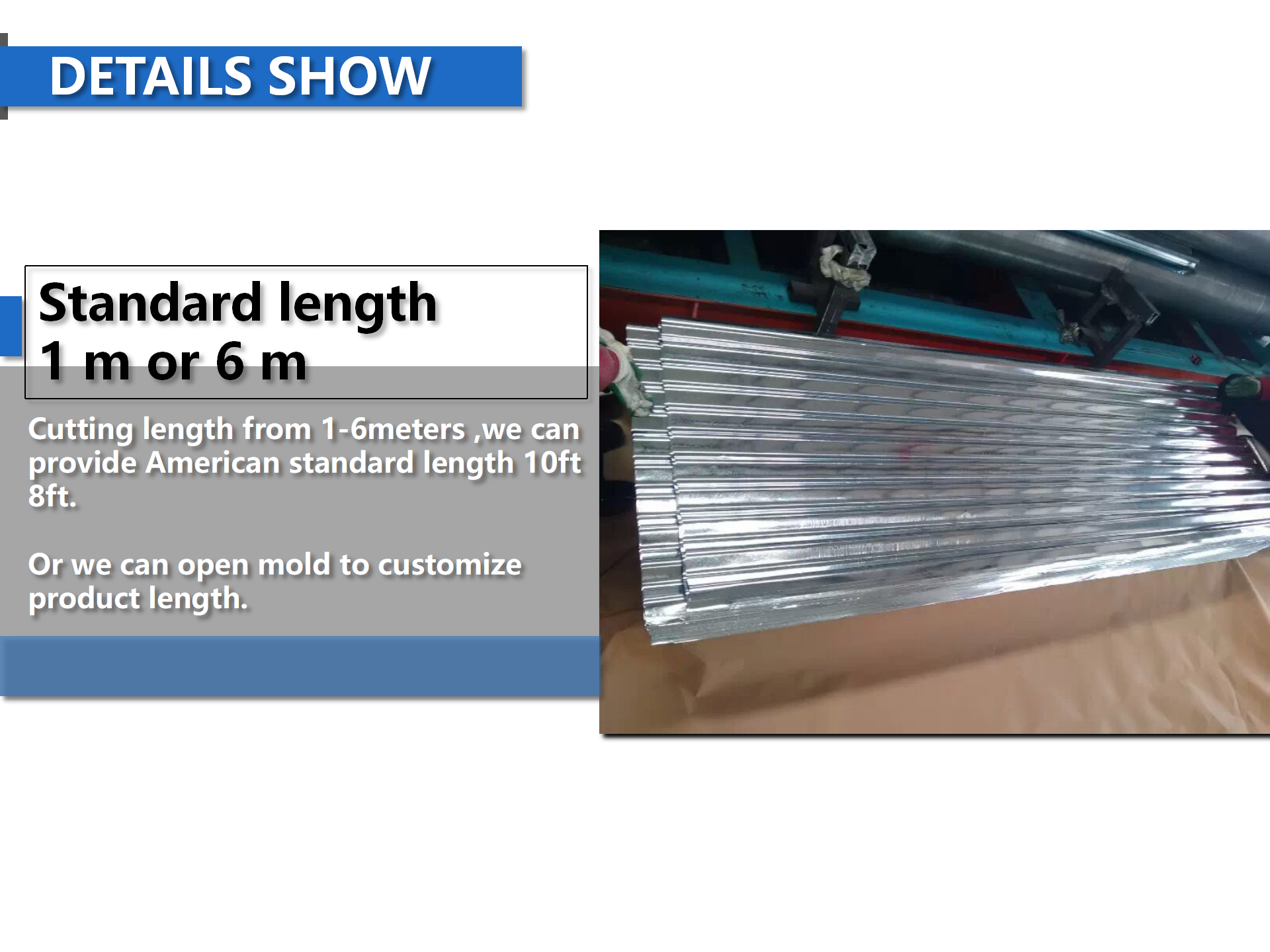

Length

|

2 - 5 meters

|

|

Tolerance

|

±1%

|

|

Type

|

Steel Sheet,Gavalume Steel Sheet

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching

|

|

Certification

|

ISO 9001-2008, CE, BV

|

|

Zinc coating

|

2-275(g/m2)

|

|

Depth of corrugated

|

from 15mm to 18mm

|

|

Pitch

|

from 75mm to 78mm

|

|

Gloss

|

by Customers' Request

|

|

Yield strength

|

550MPA/as required

|

|

Tensile strength

|

600MPA/as required

|

|

Hardness

|

Full hard/soft/as required

|

|

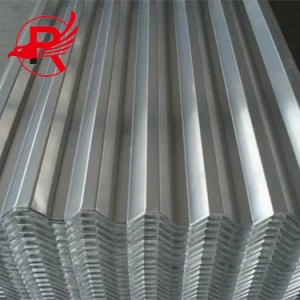

Application

|

roofing tile,house,ceiling,door

|

Steel structure house panel, movable house panel, etc.

Note:

1.Free sampling, 100% after-sales quality assurance, Support any payment method;

2.All other specifications of round carbon steel pipes are available according to your requirement (OEM&ODM)! Factory price you will get from ROYAL GROUP.

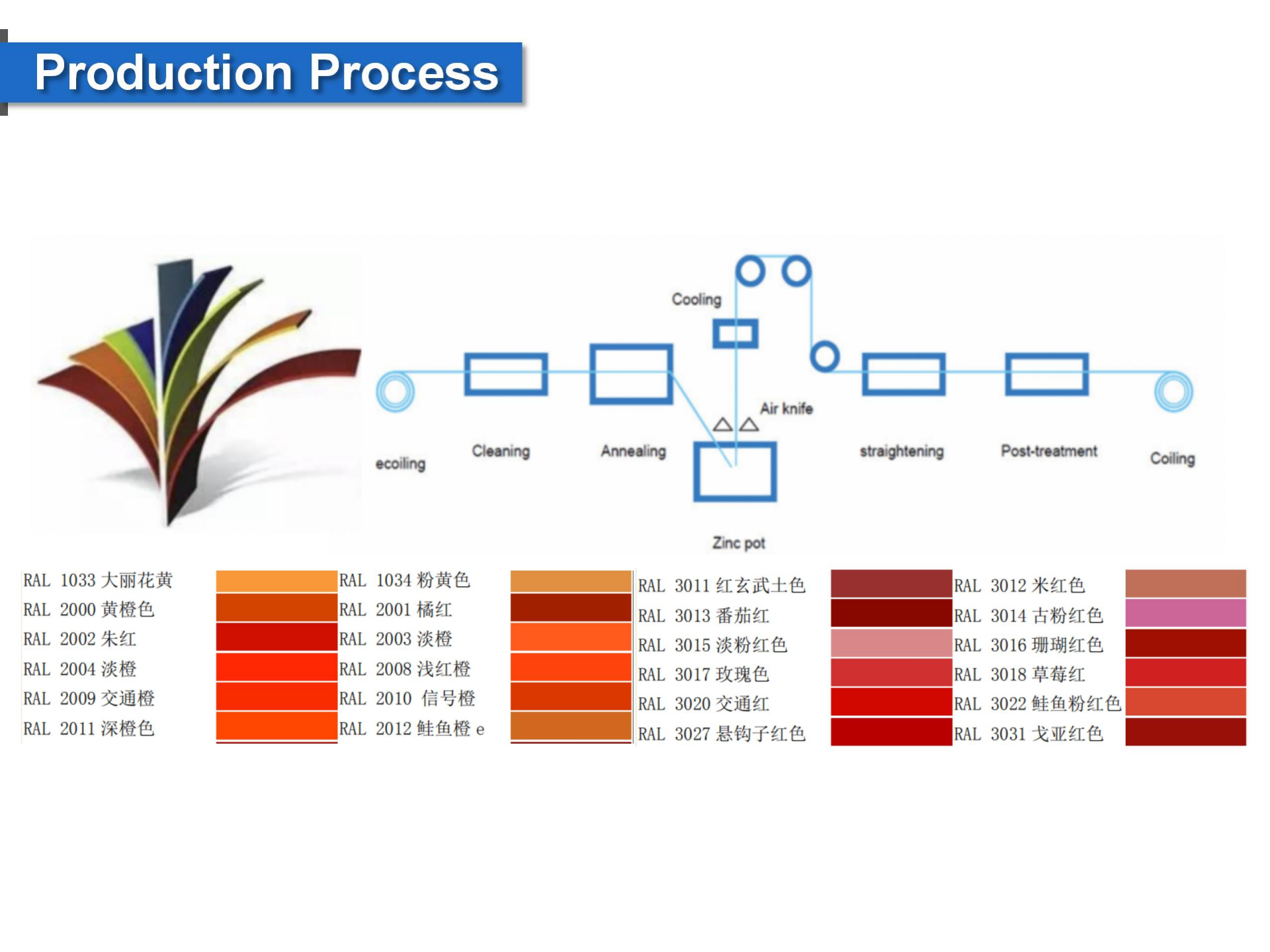

According to production and processing methods, it can be divided into the following categories:

① Galvanized corrugated board. The thin steel sheet with a zinc layer is adhered to the surface by immersing it in a bath of molten zinc. At present, it mainly adopts the continuous galvanizing process, that is, the coiled steel plate is continuously immersed in a galvanizing tank and combined with molten zinc to form a galvanized steel plate.

②Alloy galvanized corrugated board. This kind of steel panel is also made by the hot dip method, but immediately after it is discharged from the tank, it is heated to about 500°C to form an alloy film of zinc and iron. The galvanized sheet has good paint adhesion and weldability;

③Electro-galvanized corrugated board. Galvanized steel sheets produced by electroplating methods have good workability. However, the coating is thin and its corrosion resistance is not as good as hot-dip galvanized sheet.

④ Single-sided and double-sided galvanized corrugated boards. Single-sided galvanized steel panels are products that are galvanized on only one side. In terms of welding, painting, anti-rust treatment, processing, etc., it has better adaptability than double-sided galvanized sheets. In order to overcome the shortcomings of not being galvanized on one side, another type of galvanized sheet is coated with a thin layer of zinc on the other side, that is, double-sided differential galvanized sheet.

⑤Alloy and composite galvanized corrugated boards. It is a steel plate made of zinc and other metals (such as lead and zinc alloys) or even composite coating. This kind of steel plate not only has excellent anti-rust properties, but also has good coating properties.

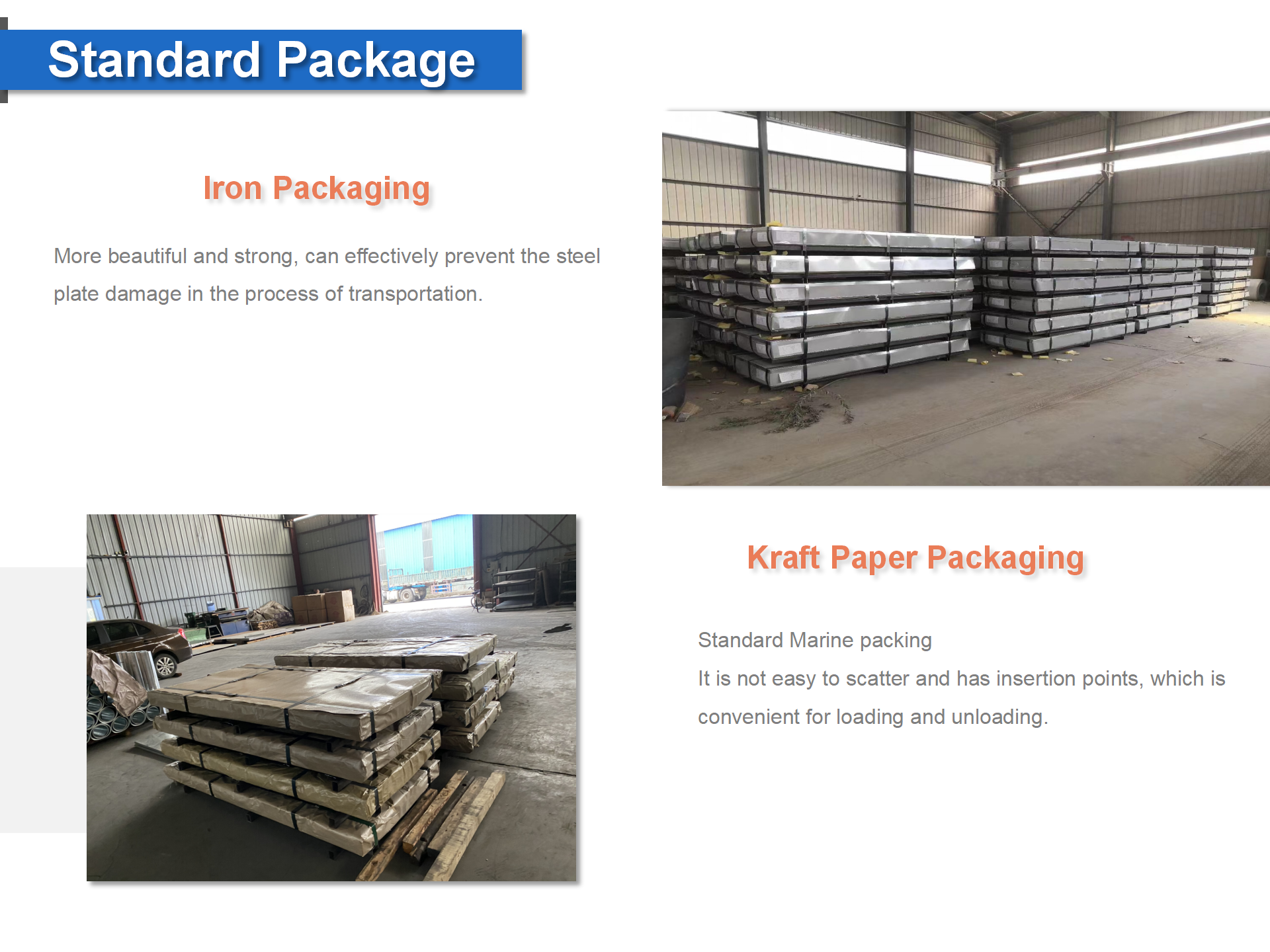

Packaging :

Steel corrugated boards are packaged and transported according to length, width, thickness and weight. Common packaging methods are horizontal and vertical. Horizontal packaging is generally made of stacked steel corrugated boards (the number of stacked layers generally does not exceed 3), and is supported and fixed with steel strips or skeletons. Vertical packaging is made of steel corrugated boards laid out longitudinally, alternately paved using interlacing or splitting methods, and bundled and cut with wooden strips, boards or buckles.

Transportation: Express (Sample Delivery), Air, Rail, Land, Sea shipping (FCL or LCL or Bulk)

Entertaining customer

We receive Chinese agents from customers all over the world to visit our company, every customer is full of confidence and trust in our enterprise.

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Daqiuzhuang Village, Tianjin City, China. Besides, we cooperate with many state-owned enterprises, such as BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP,etc.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: Do u have payment superiority?

A: For big order, 30-90 days L/C can be acceptable.

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years cold supplier and accept trade assurance.